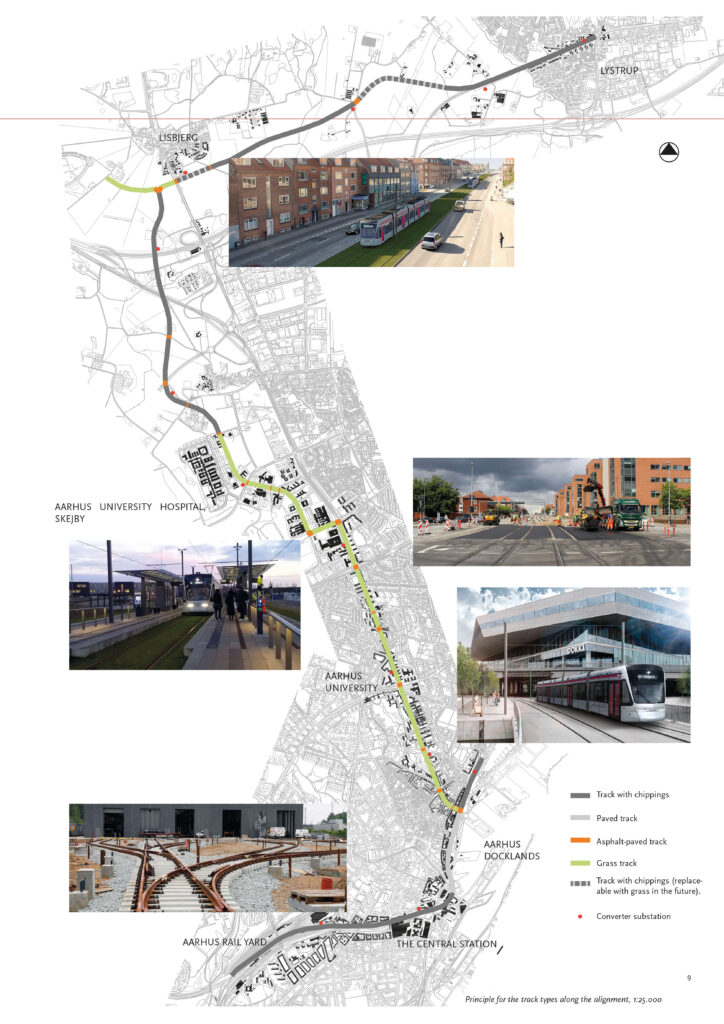

Aarhus light rail project

Combining UTS expertise for added value

- Reduced LCC and maximized product life through tailor-made hardware solutions and cross-departmental collaboration

- Optimal alignment of the objectives between customer and supplier through Vossloh’s participation in the entire lifecycle of the asset

- Studies and product-specific calculations for an optimized offer:

- Noise and vibration study to protect sensitive equipment from vibration

- DFF 200 fastening solution (former W-Tram) as a vibration-damping and noise-absorbing solution

- Floating installation of slab track with anti-vibration mats

- Rail expansion joint model for smooth gliding of the rail on bridges that required an absorption of movement in the track area