Rail replacement in the Arctic Circle: Urgent reconstruction of a section of the economically important Malmbanan line in Sweden

Rail replacement in record time

Rail replacement on one of the most important routes in the ICE network of Deutsche Bahn

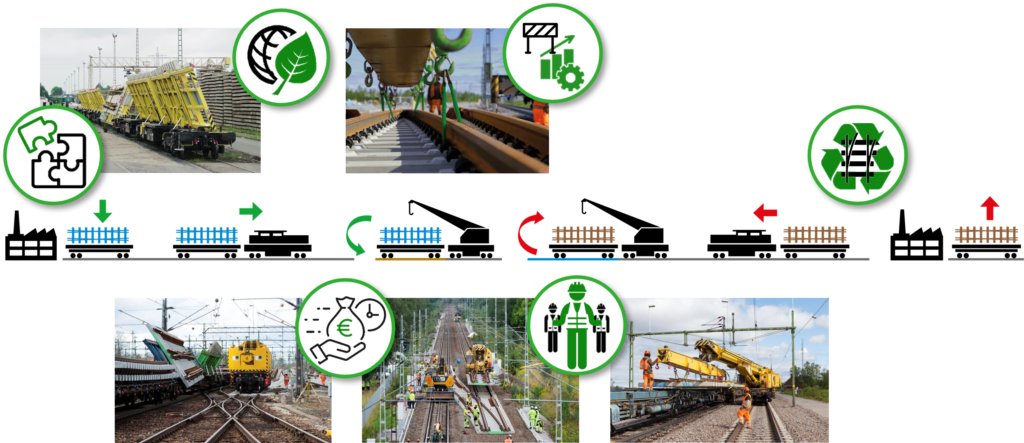

Complete portfolio of Track supply

Interface reduction thanks to extensive capacities & expertise

- 4 stationary rail-welding plants in Europe

- Well over 100,000,000 m of rail supplied to date

- Europe’s largest long-rail transport fleet with various loading/unloading and rail replacement systems

- 25+ years of experience in mobile rail welding

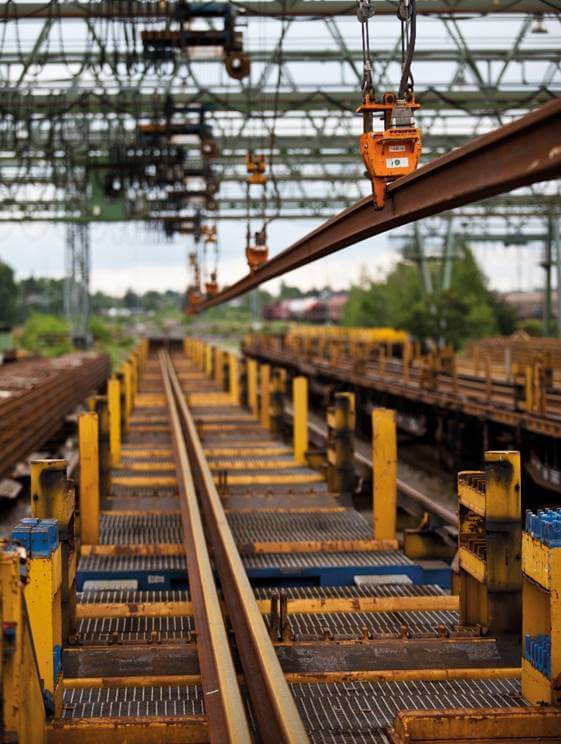

Rail Center Services: Production and assembly of welded long rails, insulating joints and profile transition joints

Long-rail production & just-in-time availability of all relevant rail profiles:

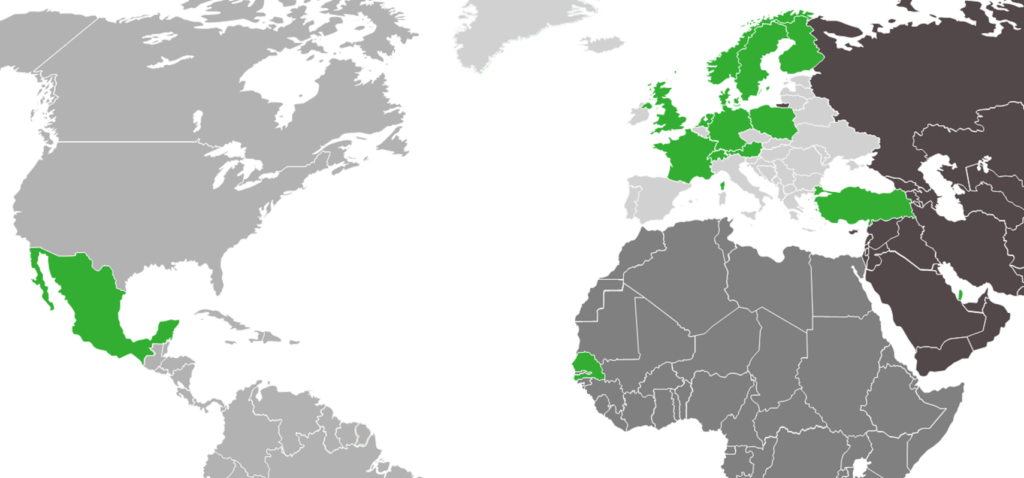

- Germany: core market since 1947, Q1 certified

- The Finnish welding plant has been part of the Vossloh Group since 2016 and supplies major national suppliers with all Rail Center services

- Denmark since 2006 (frame contract for all services)

- France since 2019 (frame contract for specialty rails & the only approved manufacturer for all transition joints in various combinations)

- Netherlands (welding & milling)

- Switzerland (welding)

- Sweden since 2012 (frame contract for transition joints)

- UK with individual components (insulating joints)

- South Africa (frame contract for transition joints)

Just-in-time logistics for rails

Long-rail transports:

- Largest fleet in Europe with 231 Robel wagons and 268 STS wagons, including the necessary unloading systems

- Precise localization via our own GPS positioning system and tracking in the web-based rail logistics portal

- Thanks to these capacities, we were able to win major DB projects and complete them on schedule.

Efficient rail installation & replacement

With the Railtainer solution, we are entering a new era in rail logistics. By increasing the loading capacity to 42 rails (60 E1) or 48 rails (49 E1) with a length of 120 m, we cover the main demand of our customers. Suitable for the transportation as well as the unloading and loading of rails. The use of standard container flat wagons as a base is our innovative answer to easily increase our fleet capacity. No loading timbers or other aids are required to attach the rails to the transport unit – a further contribution to sustainable rail transport.

In combination with our own rail loading wagons, our new generation of rail replacement wagons enables the rails to be completely replaced in the shortest possible time thanks to a highly efficient assembly line system. The rail replacement process includes welding using a mobile flash butt welding machine, unloading new rails and loading the old rails. Thanks to the high working speed of up to 4,000 meters of track per shift, closure and construction times are reduced to a minimum.

Fully automatic welding process

- Flash butt welding is one of the most advanced technologies for producing a seamless track body. As in stationary long rail welding, the rail ends are heated by high-amperage resistance heating up to the required welding temperature and are subsequently pressed against each other at a high hydraulic pressure – without the introduction of any foreign material.

- As a result of our processor controlled, fully automatic flash-butt welding process, these welded joints are less prone to failure and ensure a significantly higher strength and durability.

- On the process and machine side, we have numerous country approvals as well as sufficient capacity to successfully complete major construction sites, such as on the high-speed rail lines in Germany, as well as the Follobanen tunnel project in Norway, on schedule.

The various work steps of the flash-butt welding process, taking into account the direction of work:

Fields of application of our mobile welding trucks

Advantages and limits of use compared to other welding methods

- Higher quality & strength (about 500 kN greater bending force compared to thermite welding for rail profile 60E1)

- Greater process stability & high reproducibility of the result in mass production due to processor control ¨ No additional ultrasonic testing required

- High quantities in a short period (up to 8 welds per hour) for fast work progress

- No foreign materials are employed ¨ much safer working conditions & more environmentally friendly:

- significantly less smoke and dust

- considerably less waste, which is also recyclable

- no slag or welding residues

- no mold or packaging etc., only the sheared bead

- reduced logistical effort

- Applicable irrespective of weather conditions

- Can be used worldwide:

- Ambient temperature from -10 to +55° C

- Maximum working altitude up to 3,000 m above sea level

- Our machines cannot be used in switches and for the final weld

- Our machines are not suitable for grooved rails

- Higher costs for certification and maintenance of the machine in the respective countries where it is used

- Personnel require higher qualifications (traction vehicle driver, truck license, certification as a flash-butt welding machine operator)

- According to technical specification, smallest radius ≥ 300 m

Follo Line: Key data on currently the largest railway infrastructure project in Norway

Sneltram-Project in Utrecht: Semi-stationary welding

References on four continents

Pre-segmented turnouts delivered just-in-time

30% shorter installation time

5x faster turnout installation

In just 8 hours

References

- In addition to turnout transports in Scandinavia, France, Switzerland & the Netherlands, we also have a multi-year framework agreement with DB Netz for the delivery of pre-assembled turnout segments. From the turnout plant in Witten, we deliver to construction sites in all of Germany.

- Long-term letting, e.g. to Vossloh Cogifer in Poland

- Letting to private construction companies for construction projects in Germany or in the Netherlands, for example

- Transports including logistics services

- Operation of the WTW – especially of the hydraulic tilting process – exclusively by specially trained personnel

Customer benefits

- Uniform quality of the turnout construction thanks to the stationary production in the turnout plant

- Prefabricated, fully equipped turnout modules in plug & play design for a fast and efficient installation at the site

- Modern & environmentally friendly transport by rail

- Economic benefits through significantly shortened track construction work and reduced manpower requirements at the site. Moreover, no trackmen with turnout experience

are needed in the track – a crucial advantage

in times of personnel shortage

- High level of safety in the track

- Generally, we also offer to take the

old turnouts away for refurbishment

or disposal. - Turnout deliveries in Scandinavia, France,

Germany, Switzerland & the Netherlands - Fleet of 19 switch transport wagons in total; all with TSI approval & tracking system