Ensuring that the "traced line" is passable

Application: Monitoring the track occupancy and set track routes in “workshop areas” (kind of depots/yards used to sort and assemble the trains for the construction/maintenance of a line) or in industrial sites

Solution:

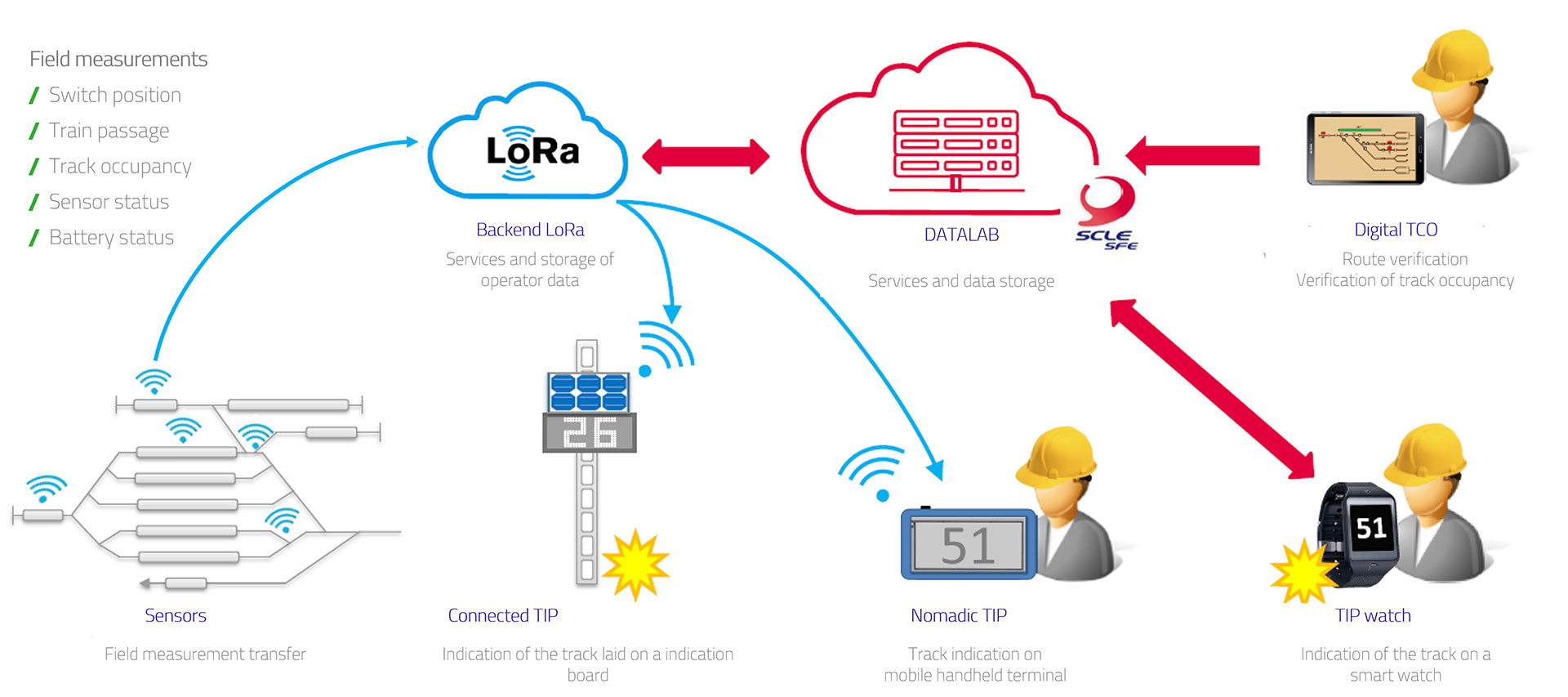

- Vossloh’s wireless switch-point detectors and axle counters, tested at the Rail Open Lab of SNCF with partner Scle Sfe, capture live information from the field and assist the operators to set the train routes on non-automated yards.

- Currently, data is collected via the Lora network, analyzed and displayed to operators in workshop areas as digital live information on a tablet and smart watch. In addition, costs can be reduced in the medium term as wrong itineraries and, in the worst case, derailments are avoided.

- The design includes a rechargeable battery and a universal mechanical fixation for any Vignole turnout without any perforation of rail or switch tongue.

- Control of switch position

- Track occupancy control

- Route planning

Support base for maintenance of railway infrastructure in Coutras

- Area: 300,000 m² (1.5 km x 200 m)

- Operation: 22 service tracks + 2 shunting drawers; 200 shunting movements in average

- An accounting of about 8,000 axles per day (½ million per yard)

- Verification of the position and sticking of about 1,000 switches per day (about 60,000 per yard)

- Number of feasible routes on the Station 4 side: ± 90

- Control of the switches from a remote station (switchman) and on site (shunter)

First wireless & connected Paulvé detectors for switch position detection & traffic detection/axle counting

Live information on the indication board, a tablet & smart watch

Green mobility intention

If we imagine that such products one day will be SIL4 approved and accepted on depot & main lines, they could widely reduce the infrastructure costs (thousand kilometers of cables & signalling system equipment like relays, cabinets, etc.) as well as resources.