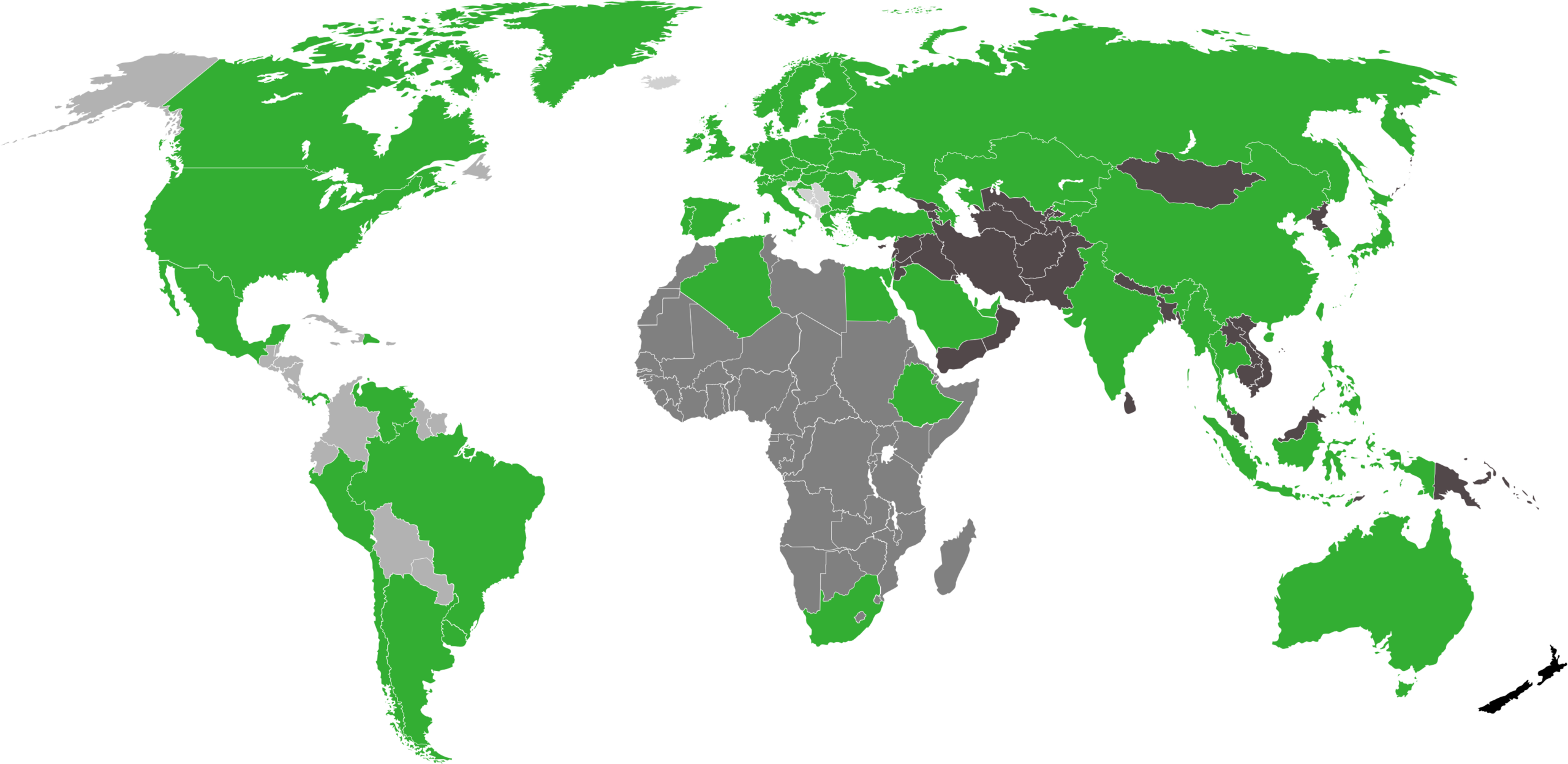

Safe ride comfort around the globe – for all load profiles

© Emmanuel Avargués; www.art-e.org

This route is completely located underground and was equipped in 2011 with cellentic intermediate plates along a track length of 22 km. Trains travel with speeds of 80 km/h at 3 minute intervals during rush hour, transporting up to 200,000 passengers daily. The Airport Line project presented demanding engineering problems since the tracks travel along a topographically difficult route: the area is prone to earthquakes and the route has extreme grades, with 40 km of track installed on viaducts. As a result, approx. 330,000 cellentic intermediate plates were installed here along a track length of 102 km. At speeds of up to 100 km/h they provide a safe and comfortable ride for about 143,000 passengers daily.

The Airport Line project presented demanding engineering problems since the tracks travel along a topographically difficult route: the area is prone to earthquakes and the route has extreme grades, with 40 km of track installed on viaducts. As a result, approx. 330,000 cellentic intermediate plates were installed here along a track length of 102 km. At speeds of up to 100 km/h they provide a safe and comfortable ride for about 143,000 passengers daily.

On China’s very first high-speed rail line, a total of 750,000 cellentic intermediate plates were installed into the slab track over a track length of 230 km. While the track is designed for 300 km/h, the route will however also support speeds up to 350 km/h.

On China’s very first high-speed rail line, a total of 750,000 cellentic intermediate plates were installed into the slab track over a track length of 230 km. While the track is designed for 300 km/h, the route will however also support speeds up to 350 km/h.

On the extension for Sukhumvit route approx. 45,000 cellentic intermediate plates were installed along the entire elevation along a 10.4 km track. Trains travel

along the route at maximum speeds of 80 km/h.

On the extension for Sukhumvit route approx. 45,000 cellentic intermediate plates were installed along the entire elevation along a 10.4 km track. Trains travel

along the route at maximum speeds of 80 km/h.

Almost a third of the route (designed for 300 km/h) consists of nine tunnels. cellentic intermediate plates were installed here on a track length of 154 km. The route has gradients of up to 20 ‰, 55 % of the

route is located along arcs with a minimum curve radius of 4.085 m

along the route at maximum speeds of 80 km/h.

Almost a third of the route (designed for 300 km/h) consists of nine tunnels. cellentic intermediate plates were installed here on a track length of 154 km. The route has gradients of up to 20 ‰, 55 % of the

route is located along arcs with a minimum curve radius of 4.085 m

along the route at maximum speeds of 80 km/h.

Urban traffic challenges for direct fastening systems on slab track

The perfect superstructure for local rail and metro lines today is the slab track, as the concrete bed guarantees a stable rail position and generates low maintenance costs. Ideally, highly elastic components are used to ensure a comfortable ride at high operational safety and low noise emissions.

- Elastic rail pads provide the following benefits:

- distribution of pressure and force

- reduced wear of wheel and rail

- increased elasticity and rail deflection of the entire system

- reduced contact stress for longer life of all components

- noticeably better ride comfort

- impact reduction.

- Hard rail pads suffer under extreme loads. The missing elasticity at the rail supporting point leads to:

- flexing in tight curves or

- increased rail wear (corrugations & head checks).

Examples of the consequences of too hard rail pads

read more

read less

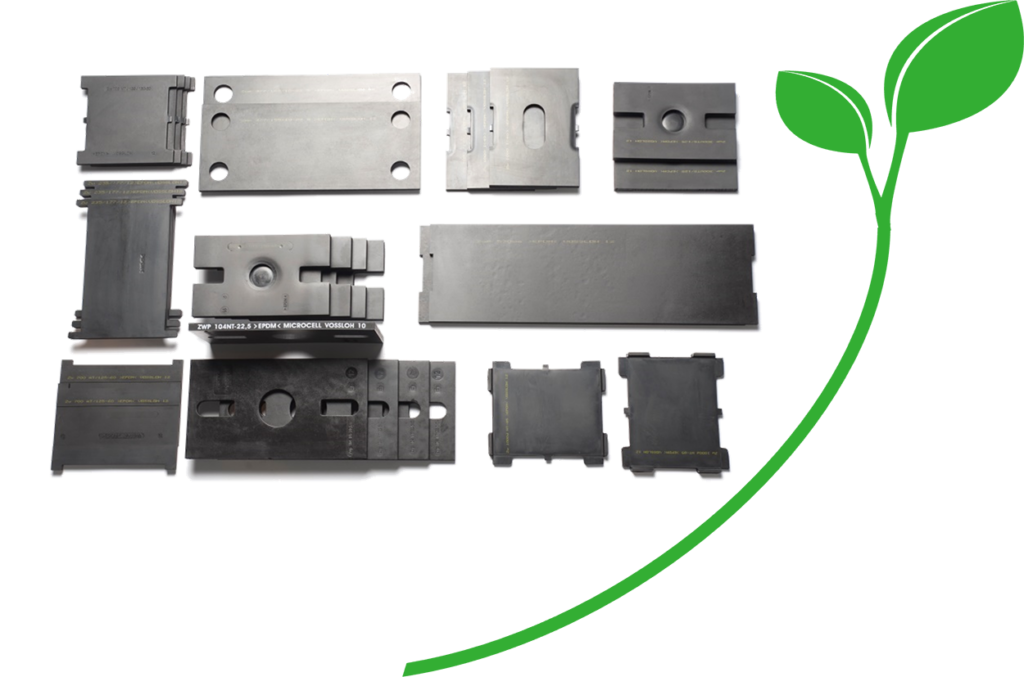

- For every rail installation variant, Vossloh offers suitable fastening systems. Their highly elastic rail pads made of cellentic ensure the elasticity of the ballasted track.

The key to success – the composition of the material

Rail pads under constant load testing:

Various materials deform to differing degrees under enormous pressure, e.g. when the train passes over them.

All components of the fastening systems are optimally attuned to each other.

The cellentic components reduce vibrations caused by track and wheel unevenness.

Thanks to its defined porosity, the cellentic pad can work within its own structure and will hardly deform under load.

Rail pads and intermediate plates allow rail deflection and can therefore optimally distribute occurring vertical forces.

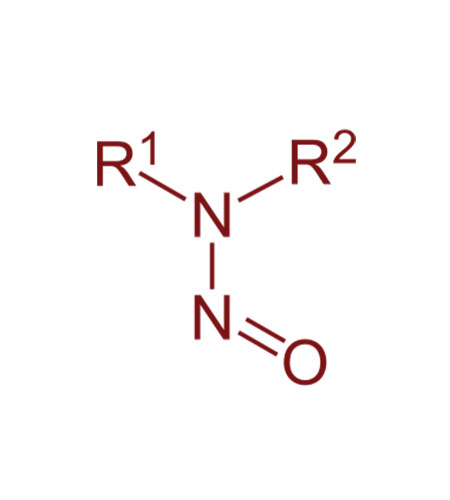

cellentic: Nitrosamine-free manufacturing process

- Carbon emissions reduced by >10 % over the entire lifecycle

- Ecological further development with eco-friendly vulcanization accelerators

- Healthier cycle in production and in the track

- Product range of rail pads & intermediate plates available as series products and as tailored individual solution

Nitrosamines are chemical reaction products that mainly occur under the influence of heat. They can be found - albeit in only small doses - in food & beverages, cosmetics and toys.

read more

read less

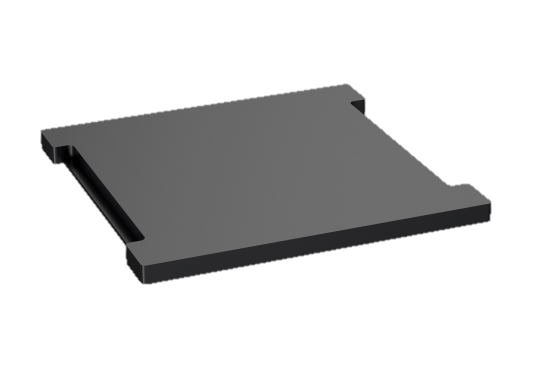

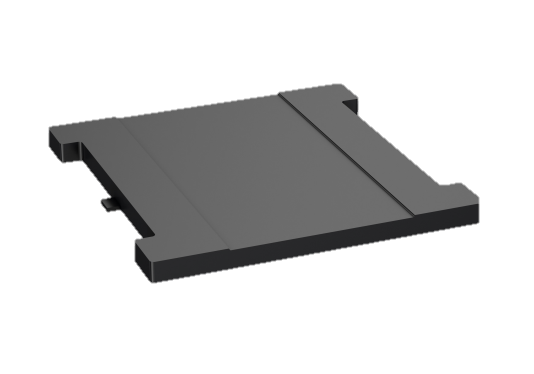

Different designs for rail pads

- Ensures that the rail pad is correctly placed under the rail and between the angled guide plates.

- For pre-assembled sleepers, the pre-assembly lips are important for the transport. They help the angled guide plates hold the rail pad in place.

- Reinforced edge areas stabilize the rail position.

- The rail behaviour is optimized by angled guide plates.

- Anti tilting (AT) protection reduces wear and tear and extends the service life.

- The AT version is provided with pre-assembly lips.

- Comprises optimized H-shape’s features for special scenarios: if high temperature variations during the track construction result in higher longitudinal displacements of the rail.

- Allows significant more flexibility during the track assembly.

- All rail pads are available in the new fin design, also with pre-assembly lips.