New M-Generation tension clamps

Worldwide it can be observed that the loads in railway tracks are increasing. As a result, rail defects are becoming more frequent. At the same time, automated trains always accelerate and brake at the same point.

Since the forces that occur must primarily be cushioned and offset by the rail fasteners, Vossloh has sought a way of sustainably increasing the robustness of rail fastening systems and, in this way, improving track position stability in the long term. The result is the new M-Generation tension clamps.

The decisive key to permanently increasing the robustness of the tension clamps against external influences lies in the significant increase in the natural frequency. Maximum safety in the track is also ensured by the multiple increase in torsional resistance, which leads to improved frame rigidity of the concrete sleeper track, e.g. in ballasted tracks. With comparatively lower life cycle costs, the M-Generation also enables higher elasticities.

Product features for first-class performance

- Ready for use in all fields of application, the increased natural frequency strengthens the robustness of M-clamps against external influences, thus extending their service life going hand in hand with reduced lifecycle costs.

- Compact product design: significantly reduced carbon emissions (use of green steel)

- Properties of the proven material are further optimized by additional micro-alloying (to guarantee fatigue limits/forces)

- Low-stress bending & improved hardening during the manufacturing process

- Increased robustness of the tension clamp & other fastening components (less wear)

- Lower weight & more compact design: lower transport costs

- High natural frequency: Strengthens the clamp robustness

- Innovative geometry with spring arms bent outwards for optimized contact points:

- Larger contact area at the rail base

- Higher torsional stiffness

- Excellent load/deflection properties: maintains the stability under extreme conditions over long periods of time

- Compact design: no risk of damage during tamping

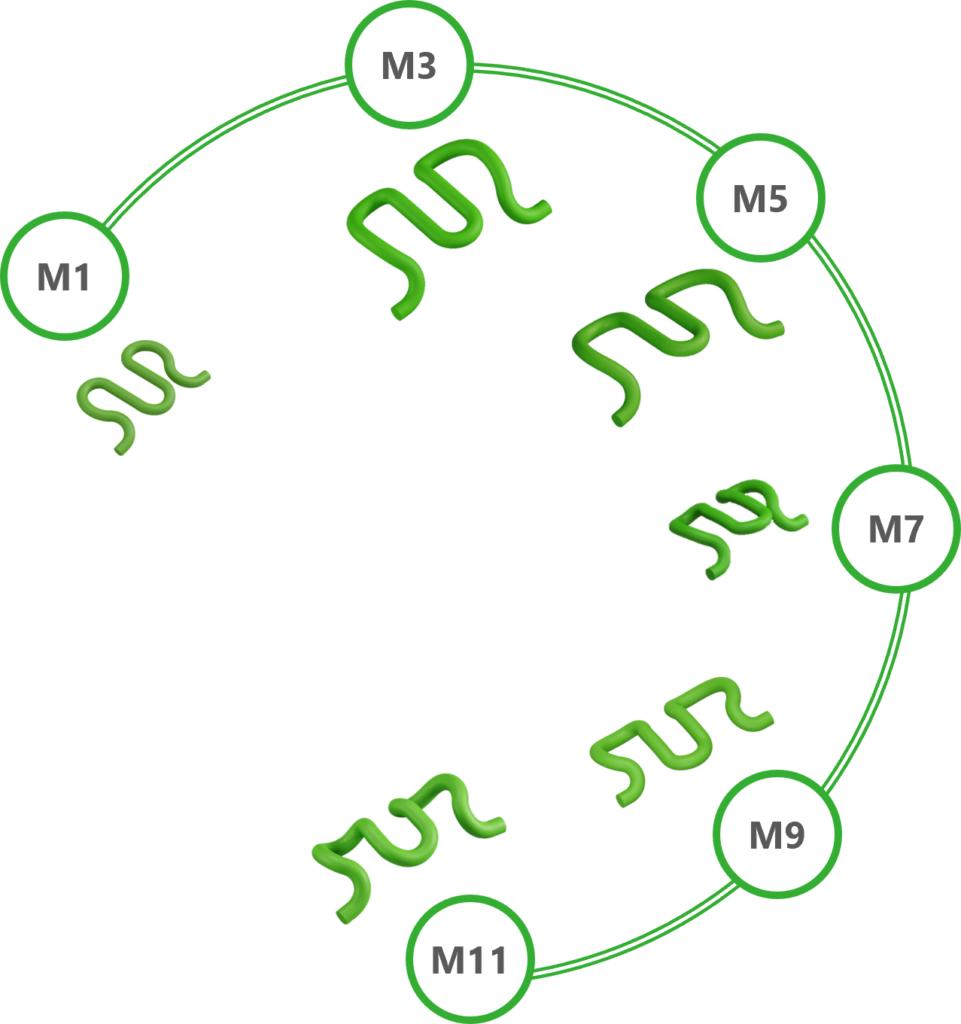

M-Generation

Expansion of the portfolio in light rail traffic & for high-speed lines

- M1: for the superstructure in light rail traffic with tight bends & maximum flexibility

- M3: Successor to the Skl 15 in the high-speed, mainline & light rail traffic sectors

- M5: reinforced M3 for increased requirements in high-speed traffic (>380 km/h & higher dynamic loads) as well as in heavy-haul applications; 25 % higher toe loads & high rail creep resistance

- M7: Alternative to the Skl 1, Skl 14 and Skl 21 in the mainline, metro & high-speed ballast track segments

- M9: Alternative to Skl 14 R, Skl 30, Skl 40 and Skl 42 for heavy freight traffic or routes with extreme requirements

- M11: New development for applications on ribbed plates (indirect fastening) with optimized geometry and improved properties.

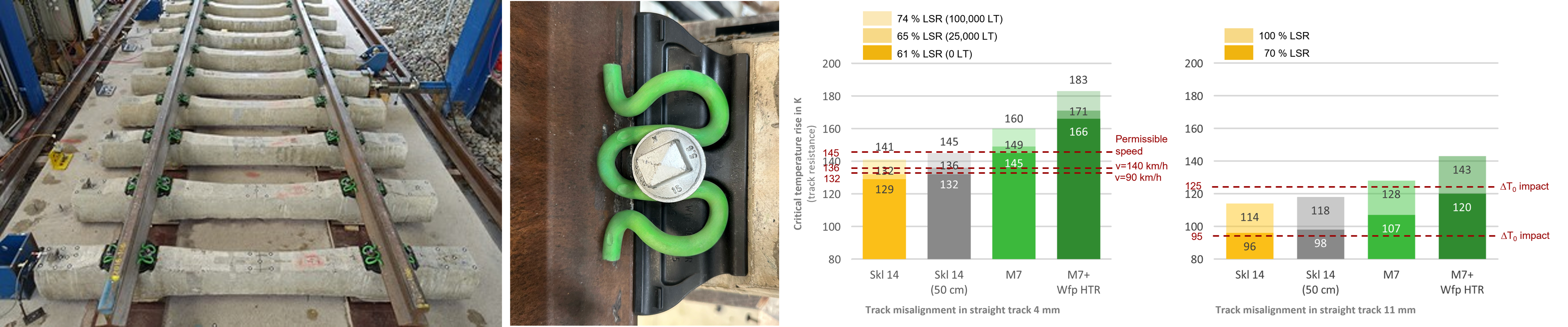

Installation of the M9 in an extremely demanding European track

M9 on heavy-haul lines in the US

M7 on an European track

Already in service in China and India, the M3 has been also installed in the German network for trial purposes since 2021

Installation of the M3 with PORR precast panel

Keeping rail on course for the future

User benefits

- Increasing the service life & thus the sustainability of the rail fastening system

- Innovative, compact design reduces transportation costs & reduces potential conflicts on the rails

- Ensuring long-term track availability & safety of the track

- New micro steel alloy reduces CO2 emissions by up to 65%

Features

- 100% improved torsional resistance for a significant increase in lateral track stability: more safety of the track despite climate change

- Natural frequency >1000 Hz leads to a more robust tension clamps in heavily loaded tracks & thus to lower LCC

- Higher fatigue strengths offer the possibility of increasing the elasticity of the rail

- Excellent interaction of mechanical properties: maintains lateral track stability under extreme conditions over an extended period of time

WfP HTR (High Torsional Resistance)

A safe future in rail despite increasing global warming

User benefits

- Reduces thermally induced track buckling & ensures greater safety of the track

- Long-term increase in track availability

- Less wear due to the larger contact surface to the rail & sleeper extends the service life of the rail fastening

Features

- Torsional resistance improved by >400%: for an extreme increase in lateral track stability, for use on bridges & in transition areas as a result of additional compressive forces in the rail

- Use in tight bends: more safety against track buckling & less wear on the Wfp

- No speed reductions necessary after the tamping process in the track: track availability is ensured

- Possible alternative to ballast widening in front of the sleeper head: resource

and cost reduction - Use in the special area of mud regions or white ballast areas

References

- Germany

- Bulgaria

Combined use of M-Tension Clamps

Preventive Solution

- Multiple increase of the torsional resistance (VDW) & thus significant improvement of the frame stiffness of the concrete track in the ballasted superstructure.

- Some state railway companies are considering adopting the M7 as the standard due to the tendency towards higher temperatures.

- In addition, lateral track stability can be significantly increased again on sections of track subject to particularly high loads in conjunction with the Wfp HTR.

- Increased safety & simultaneously

- reduced LCC due to reduced wear & a longer service life of the fastening system & the entire superstructure

- increased elasticity of the rail fastening systems in combination with the M-Generation tension clamps.