With the new highly elastic 336 rail fastening system for slab track, Vossloh offers rail infrastructure operators an optimum solution when criteria of structure-borne noise play a special role, as is currently the case in Melbourne with the metro tunnel project. The construction of the 9.5-km twin rail tunnels between South Kensington and South Yarra with 5 new underground stations is the largest public transport project in Victoria so far. As track/system supplier primarily responsible, Vossloh is implementing together with PORR different superstructure solutions for slab track optimally tailored to the line-specific needs.

A compelling and customer-oriented overall concept for an optimized noise & vibration control

In order to meet even the highest customer demands for noise & vibration control, the 336 system is used on the vibration-critical tunnel sections. Its very low stiffness of 8.5 kN/mm was thoroughly tested and confirmed in high-frequency dynamic tests at Müller BBM. In the transition between the classic form of slab track and a “floating slab track”, the stiffness range of the 336 is between 10 and 15 kN/mm.

The other permanent way solutions in the metro tunnel project were realized with the mass transit version of system 300 (formerly 300 UTS).

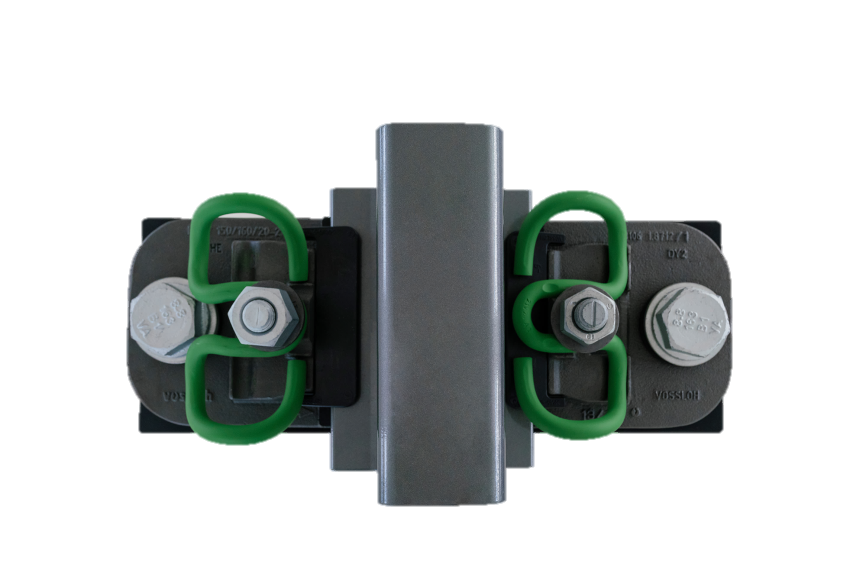

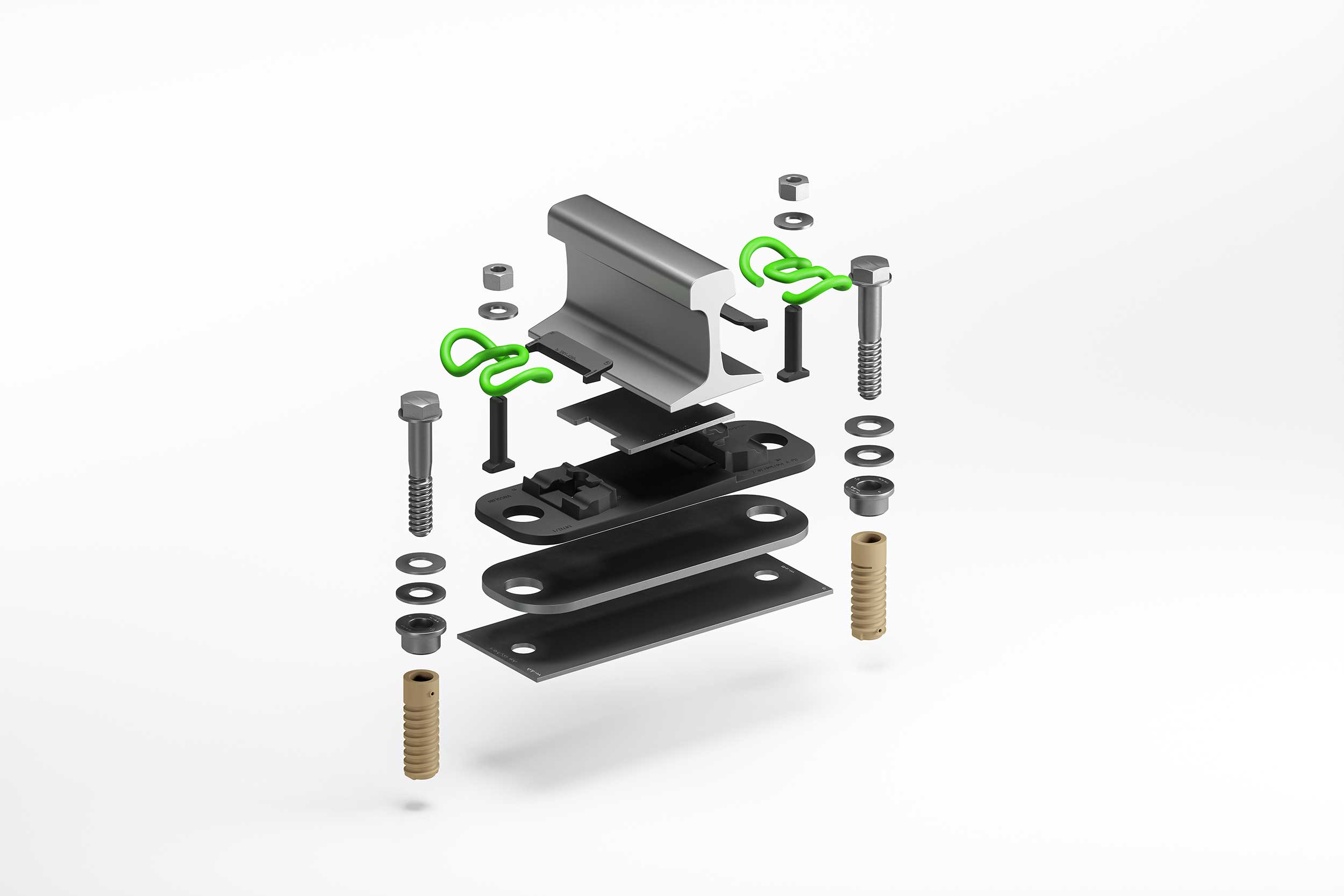

Main components of the system 336

- Pre-assembly of the fastening components possible

- Safe anchoring in in-situ concrete with two anchors – also in curves

- Optionally also available as an asymmetric system

- W-shape of the Skl 21 provides safety

- Tilting protection, rail creep resistance, maintenance-free

- Protected against corrosion by Vossloh protect

- Screw-dowel combination with trapezoidal thread for a secure clamping (alternatively: anchoring with anchoring bolts)

- Isolating bush (distance bush) for the stable clamping to the in-situ concrete or the intermediate rail plate

- Isolatorfor additional electrical insulation / lateral adjustment

- Rail pad for additional minimization of vibrations and structure-borne noise

- Ribbed plate - in the highly elastic system design with friction-modified bushes

- Intermediate plate for high vibration damping (highly elastic design with up to 8 kN/mm possible in combination with friction-modified bushes)

- Intermediate plate for electrical insulation

Production & Logistics: From preparation to storage at PORR

“The cooperation in our first joint slab track project in Australia is very good. Through Best-for-Project-Engineering, we make an important contribution to the track quality and longevity of the new metro tunnel link through Melbourne.”

Markus Halper, Department Head Large Projects and Slab Track International at PORR