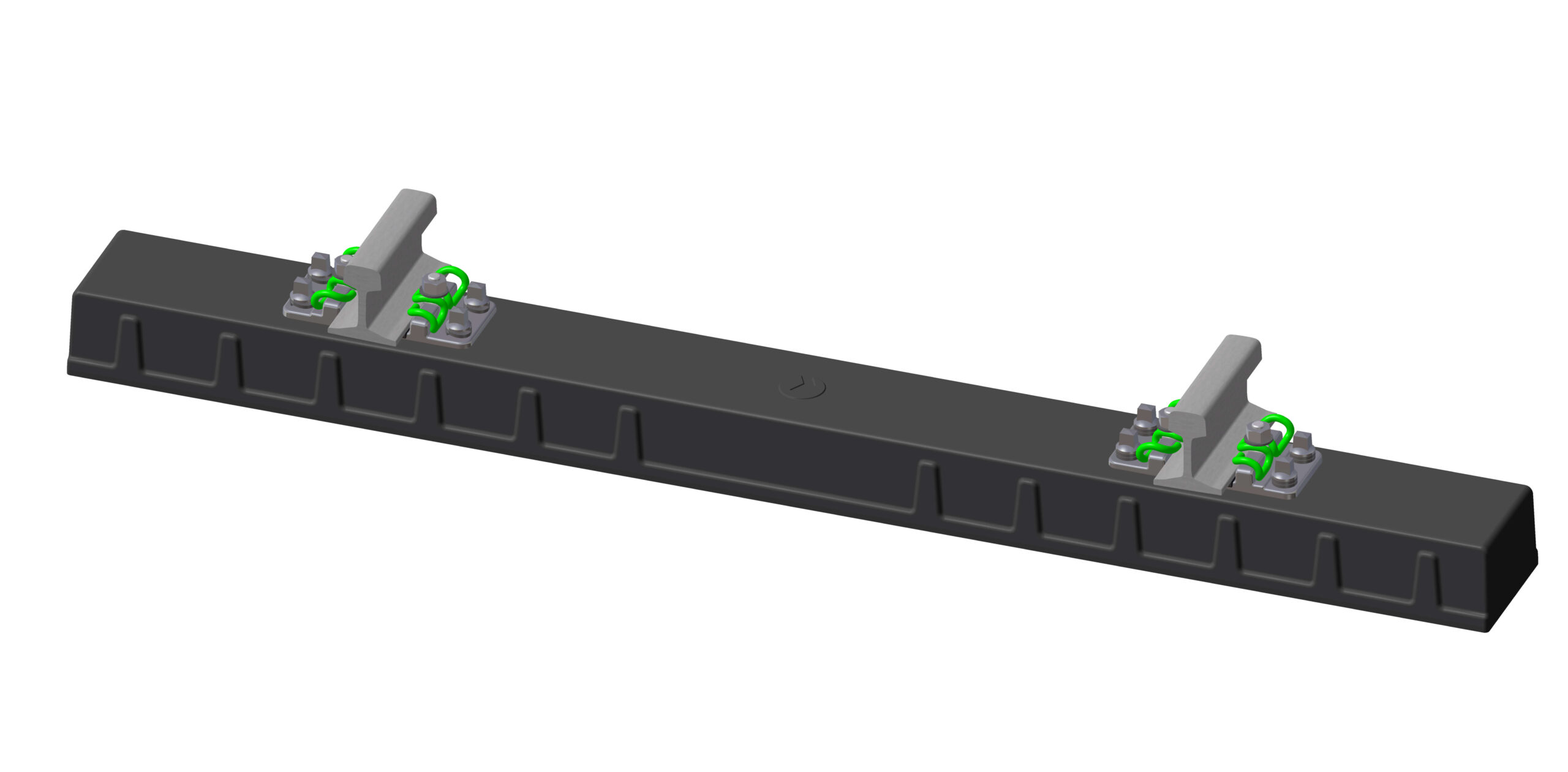

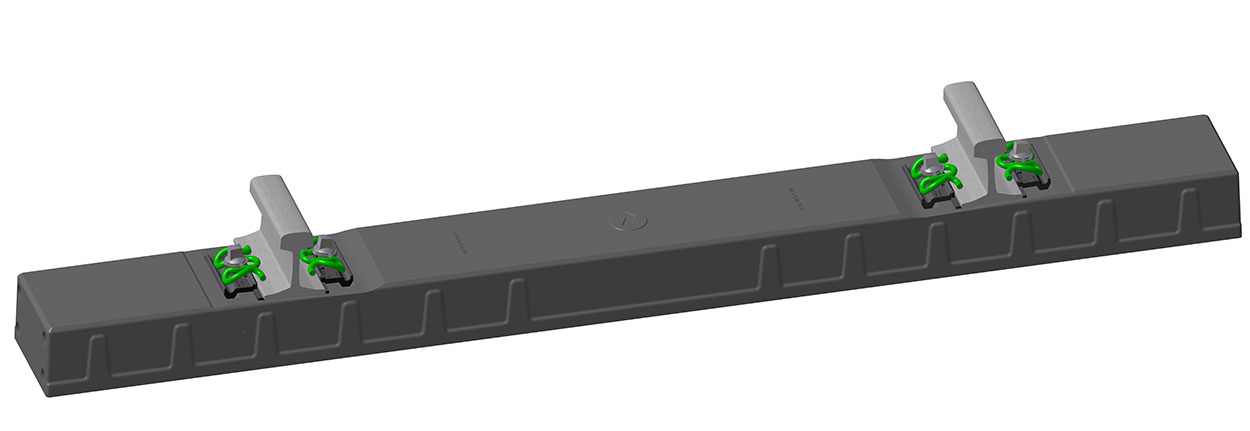

Engineered Polymer Sleeper (EPS) made of amalentic

Progressive expansion of competencies

The reason why: economical & eco-friendly compound sleeper alternative for track, switches & bridges

- The objective: an ecological compound sleeper that combines the positive features of wooden and existing plastic sleepers

- Increased safety thanks to the incorporation of reinforcement (as with concrete sleepers)

- Initial market situation: planned creosote ban for wooden sleepers in Europe

- Further motivations for the development: “enabling green mobility”

- Confidence in own competencies & abilities: interaction during wheel-rail contact & Technology Centre in Werdohl for all test scenarios

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

Overview of product properties

Sustainability

- Scheduled creosote ban in Europe: environmentally friendly alternative to wooden sleepers without any use restriction

- Use of secondary raw materials in industrial quality

- 100% recyclable & resource-saving

- Preservation of the tree population

- Consistent material quality

- High weather resistance (UV resistance, no moisture absorption) for applications in extreme, humid climate conditions

- Long service life

LCC

- Good price-performance ratio for all-inclusive deployment & series production

- Significantly less maintenance effort & high durability > low life cycle costs

Operational safety

- Defined & consistent properties

over the whole service life - Low coefficient of thermal expansion

- High lateral track set stability & stable gauge:

- High anchoring pull-out forces

- Increased safety due to the use of reinforcement (as with concrete sleepers)

- High electrical resistance

- High lateral sleeper resistance

Operational safety: Economical & eco-friendly sleeper alternative for track, switches & bridges

- 150+ test characteristics were identified

- About 330 in-house trials were carried out to achieve the optimum material compound that satisfies the international standards

and customer requirements - Investigation of the impact of environmental temperatures on mechanical properties

- Participation in the ISO and AREMA standardization committee for plastic sleepers: findings can be applied to the sleeper definition, and changes in the standards can be integrated in the product design at an early stage.

Focus on various application fields

- Wide range of application from urban transport to heavy haul already possible; focus for the future: safe deployment in tunnels

- No restrictions regarding design and moulding

- Mixing ratio and sleeper shape as well as the positioning and type of reinforcement can be adapted to application-specific specifications

- Combination with various rail fastening systems, also including W-systems

- Apart from the indirect fastening, the material and the production are excellently suited for direct fastening applications.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

Wide range of customization options: For an accelerated / simplified installation process

- Customers can choose between different rail fastening solutions – direct or indirect including safety guard:

- For W systems, the bead can be prefabricated for direct fastening.

- For switch designs: indirect fastening including guide rail and safety gear is also possible.

- Non-slip profiling with millimetre-precise embossing from two to five mm in height

- Tried and tested processing options: drilling, sawing, milling and grinding

- Prefabrication of the core holes for the sleeper screws: with and without tread, also inclined by 5°

- Adaptable sleeper geometry (length, height, width)

Long since in test operation – in various line environments

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren