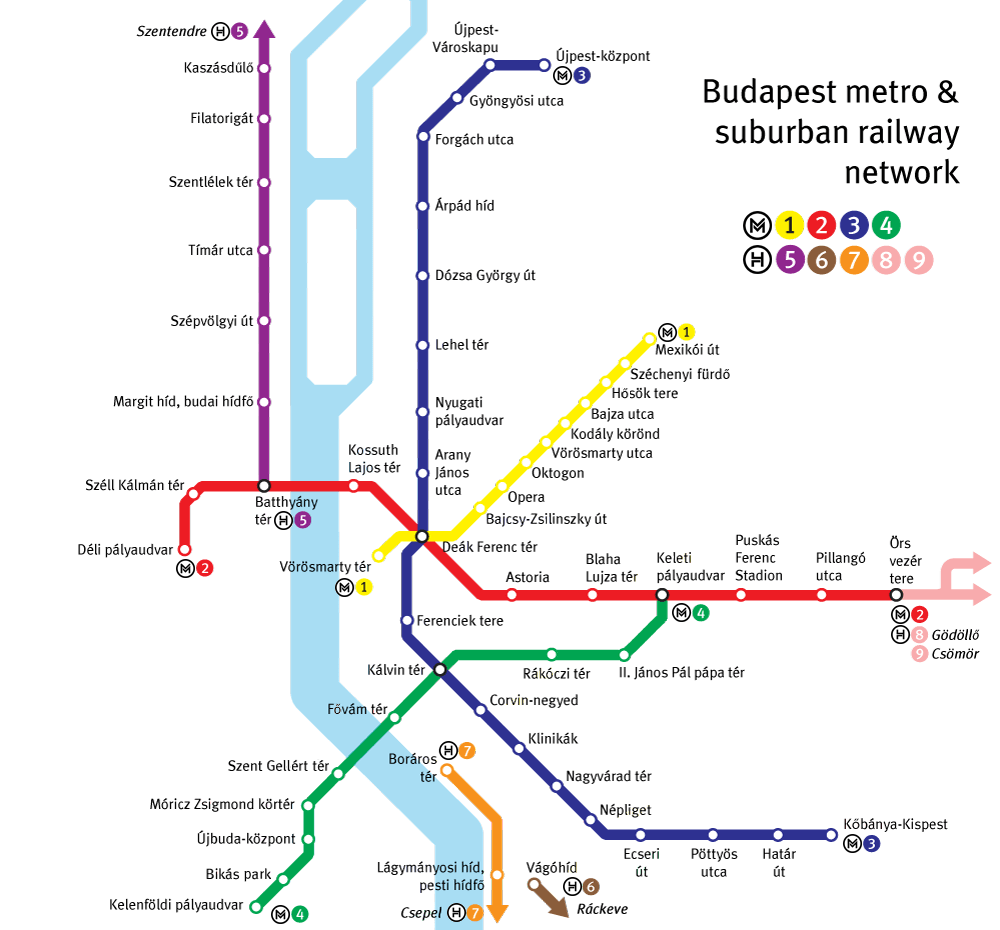

Refurbishment of the superstructure of the M3 metro line in Budapest

Highly elastic rail fastening System 336 for a reliable noise and vibration damping

Comprehensive analysis of the most important technical line characteristics, such as construction data, environment of the horizontal and vertical alignment and superstructure data

Recommendation on the basis of the gathered information and the far-reaching experience from previous projects for the Budapest metro

(reconstruction of the M2 metro line nearly ten years ago and construction of the new M4 metro line that started its service in 2014):

- Variant 1: system 336 with cellentic intermediate plate with a stiffness of 10 kN/mm to achieve the generally required noise reduction by 5 dB compared with the current condition

- Variant 2 for line sections requiring particular noise control: system 336 with cellentic intermediate plate with a stiffness of 17 kN/mm for a reduction by 10 dB.

Determination and examination of shocks and their impact on the dynamic interaction between vehicle and track:

- Performance of required superstructure computations for the customer-specific variants in the own Technology Centre

- Acoustic test concerning the required shock protection and certification of the system’s suitability by external experts

Independent metro engineering test and approval of the offered variants of system 336 by the Budapest University of Technology according to EN 13481-5 for slab track: use of the two-bolt variant for straight line sections and larger curve radii as logistical and economic alternative; for tighter curve radii of < 500 m, use of the four-bolt variant for higher stability

Project-specific advantages of the system 336

- The system 336 not only combines the advantages of the KS standard fastening system with the highly elastic bearing of rails but, thanks to its modular design, also allows a flexible adaptation to the local conditions (e.g. gauge adjustment by ±10 mm and height adjustment by +20 mm) and also does not require regular maintenance during the service phase.

- For higher stability, the distance between the fastening systems is shortened from 95 to 65 cm.

- An effective reduction of vibration emissions is ensured by the elastically borne ribbed plate.

- Anchoring in the concrete slab is made with anchoring bolts with enhanced protection against corrosion through Vossloh protect.

- Finally installed, the tension clamp offers a vertical fatigue strength of 2.5 mm; its high toe load ensures longitudinal and vertical holding forces. Highly elastic spring arms hold the rail safely in place, and the middle bend offers an additional protection against tilting of the rail.