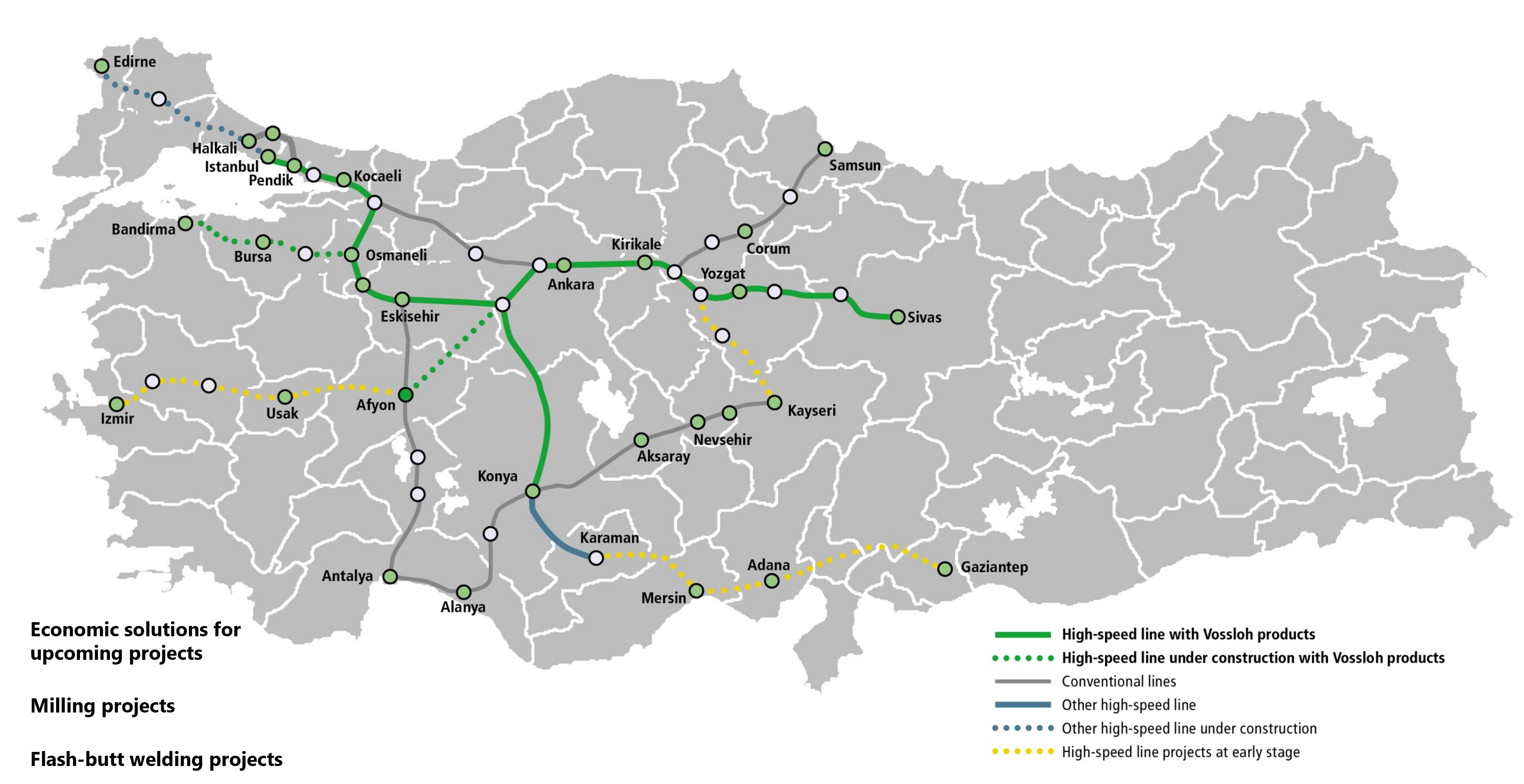

Current high-speed network incl. construction projects of Türkiye

Fastening system DFF 21 & KS system for M1B Yenikapı – Kirazlı Metro Line.

Fastening system 336 is used in M2 Yenikapı – Hacıosman Metro Line.

Fastening system DFF 21 is installed in M3 Kirazlı – Kayaşehir Metro Line.

Vossloh turnouts are installed in M2 Taksim – 4.Levent Metro Line.

Marmary project

For the prestigious Marmaray project, which has been linking Europe and Asia by rail since 2013, Vossloh supplied the systems W 14, 300, DFF 300, KS 24.

The centerpiece is the rail tunnel, which run 56 meters below the seabed of the Bosporus. Eleven prefabricated tunnel tubes were sunk and assembled underwater for the 1.4 kilometer long route. The project includes a total of 76 kilometers of new rail system. Work was originally scheduled to be completed in 2009, but during construction of the Yenikapi station, workers came across remains of the ancient port of Byzantium. The line is predominantly a triple-track; two tracks are reserved for local traffic, one for long-distance traffic. The mainline track has passing places every four to five kilometers. The tunnel under the Bosporus is double-tracked.

High-speed line Ankara – Sivas

Phase 2 Yerköy – Sivas: YapıMerkezi

High-speed line Bandirma – Osmaneli

High-speed line Ankara – İzmir (Ankara İzmir Yüksek Hızlı Tren – AİYHT)

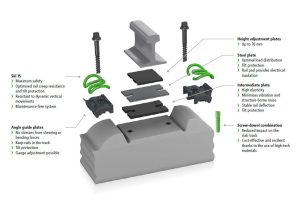

Economic solutions for upcoming projects

Swing nose crossing with 2 reinforced rails – not welded – ensure rolling rails, cradle & wing rails:

- double direct locking of the point

- elastic embedding of the point onto the splice rail to prevent any longitudinal movement

- safety plate ensures stability to prevent any movement

- point and locking detectors housed in the frame

W 21 T direct fixation without

steel base plates for intermediate sections lower the costs

One point machine with single back drive, locking device & point detectors

Notched concrete bearers permit cables & rods passage with same performance as standard bearer

applied for HSL Ankara-Konya

Resource-efficient design for conventional rail and high-speed systems: The refined System 300: Less material with no impact on quality

The extreme speeds represent a huge stress test for rail fasteners; all forces generated have to be cushioned and offset first and foremost by the rail fasteners. With physically optimized tension clamps and weather-resistant highly elastic components, our customized solutions ensure a comfortable ride experience and maximum safety. Vibration damping also helps to extend service life of all components in the track bed structure, which ensures that cost-effectiveness is not left behind.

The refined System 300 was installed for the first time in the 425 m long Catalca Gökceali tunnel.

Most advanced welding technology for producing a seamless track body

Chronology of projects with starting dates

2010 Ankara – Konya HSL

2013 Kızılay – Koru Metro Line

2014 Kızılay – Batıkent Metro Line

2014 Ankara – Kırıkkale Conventional Line

2014 Gebze – Pendik Section HSL

2015 Kayseri – Şefahatli Suburban Line

2015 Erzincan Suburban Line

2016 Eskişehir HSL Terminal

2016 Sivas – Kangal Conventional Line

2017 Maraş – Narlı Suburban Line

2017 İzmir – Harbor Connection

2017 Adana – Yenice Suburban Line

2017 Adana – GaziAntep – Maraş Terminals

2018 Kabataş – Mahmutbey Metro

2019 Ankara – Eskişehir HSL

2019 Yerköy –Sivas HSL

Between 2020 and 2022 various projects in Europe

2023 Bakırköy – Kirazlı Metro

Keeping the rail infrastructure in shape: Project Aliaga – İzmir

We are pleased that rail milling is “picking up speed” again and that we are in concrete talks with customers.