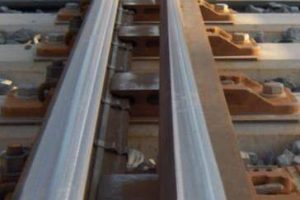

Used in combination on switches and crossings

- With Flexis, Vossloh has an all-round system for the maintenance of entire switches and crossings including parts like the frog and point blades that cannot be accessed by bigger machinery.

- It combines precise measurement methods with versatile machines in order to machine adequately and economically and do justice to the unique nature of every turnout when it comes to care and maintenance.

- Material removal from preventive to corrective (up to 1.5 mm) and removal of isolated defects using welding

- Electric Flexis machines are also available if reduced exhaust and noise emissions are required.

Procedural sequence:

- Preliminary inspection: analysis of condition and location of switches, level crossings and rail expansion joints

- An inspection and grinding work is carried out at the beginning of the shift in accordance with the applicable standard and the requirements specified by the customer

- Measurements: material removal, longitudinal profile, transverse profile and eddy current testing

- Grinding using

- corrugation grinding machine to grind the running surface (metal removal and longitudinal profile)

- Flexis grinding machine to grind the gauge corner (transverse profile)

- deburring machine and

- hand machine tools (angle grinder, e.g. for the backs of point blades)

- Continuous inspection in order to monitor machining progress

- Final inspection after the goal of the work has been achieved (removal of defects, reprofiling or new profile)

read more

read less

Switch machining: Efficiency and high quality as required

- Frog including ramp and wing rails

- Points and stock rails

- Rails including transition point and insulated joints

- Number of staff can be varied depending on size of switch

- No disassembly of trackside switching equipment needed

- Track vacated quickly enabling work during intervals between trains

- Work starts immediately at start of track possession

Special applications

Due to their construction, rail expansion joints cannot be machined by heavy rail-reprofiling machines at all, or else only with considerable logistical effort. As a consquence, they are mostly overlooked. For the purpose of comprehensive track maintenance, Flexis machines have virtually unlimited adjustment options, which allow expansion joints to be resurrected to near-perfect condition very quickly.

Closing the gap with a special rail profile: In the Netherlands, Flexis is the ideal complement to heavy, output-oriented, rail-reprofiling machinery for adding small areas e.g. switch and crossing connection points, to the overall end result.

Skid spots usually occur as single defects. They form on:

- gradients ahead of signals and

- in places with stop-and-go traffic.

These sections of track are only short, so deploying heavy rail reprofiling machines is not worthwhile in most cases. The versatile, independent Flexis technology, however, can very quickly rectify isolated rail defects such as squats, indentations or insufficiently smooth rail welds.

Train lines like the one for the Mont Blanc Express in France with longitudinal gradients of >40 ‰ are classed as lines with steep gradients. They cannot be used by standard rail vehicles unless special requirements are met, such as an extra brake locomotive or similar. Thanks to the autonomy of the deployment options that Flexis offers, even lines with steeper gradients can be machined without having to go to great expense.

Gritting in winter is particularly heavy at asphalt level crossings. Road vehicles inadvertently spread the grit over the entire crossing area, where some of it also comes to rest on the running surfaces of the rails. The next train that comes through the crossing runs over this grit, which causes severe damage to the rails in and around the crossing.

With the Flexis System able to access tracks from roadways, defects of this kind can be rectified very quickly.

Special applications

Even when spalling occurs on hardfacing, the rail can still be saved if it has sufficent wear reserve.

In Le Havre, the Flexis team removed around 2 mm from the grooved rail below the wide or double channel – the Heat Affected Zone .