Pioneer in preventive rail maintenance

- Mill-scale removal, head-check prevention and the removal of corrugations and greasy residues

- Effective alternative to the grinding procedures used on specially monitored track

- Switches with spring-action frogs without check rails can be machined as well

Capacity increase in the German high-performance network due to condition-based grinding

Active defect prevention avoids rail defects, slow running points and rail replacement

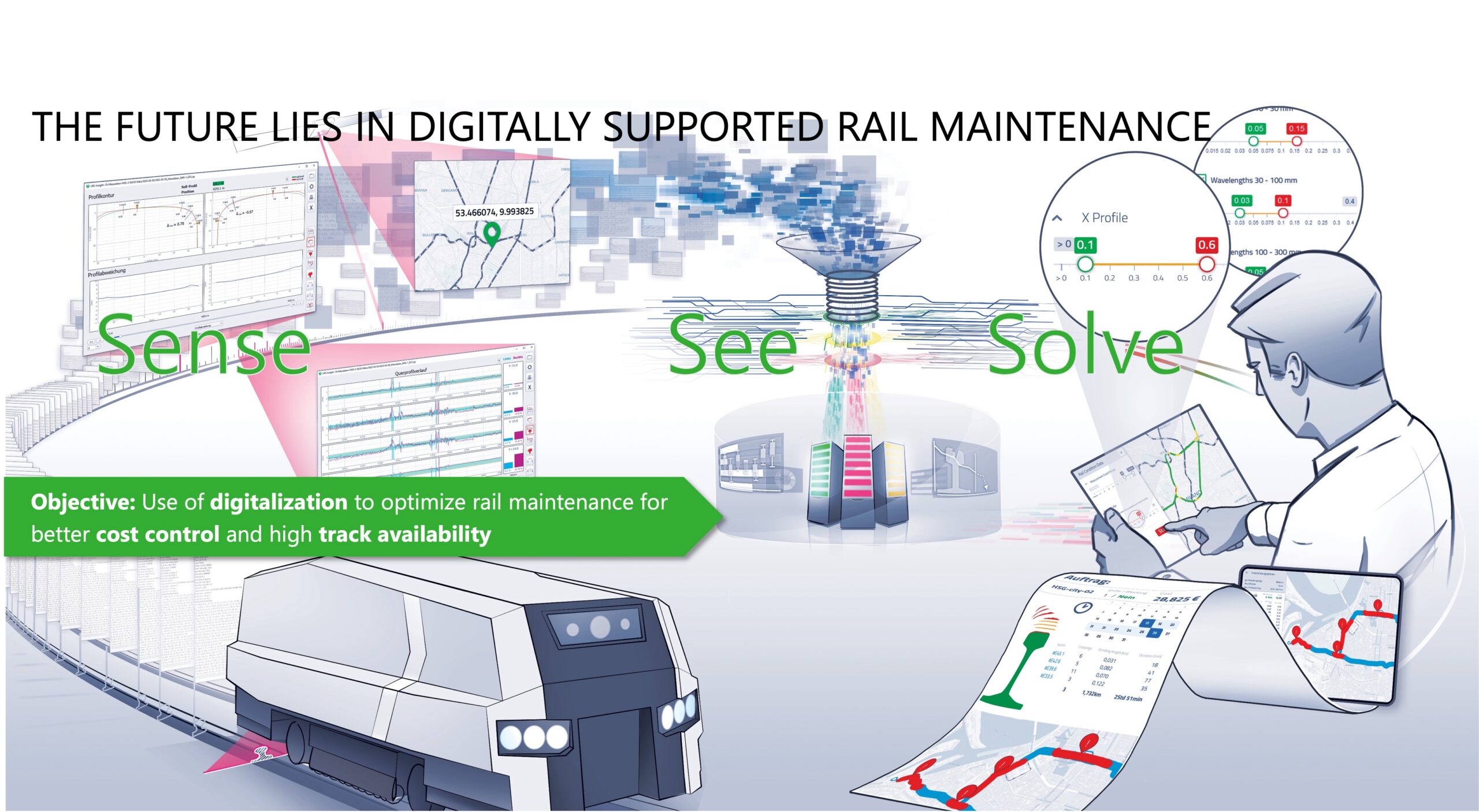

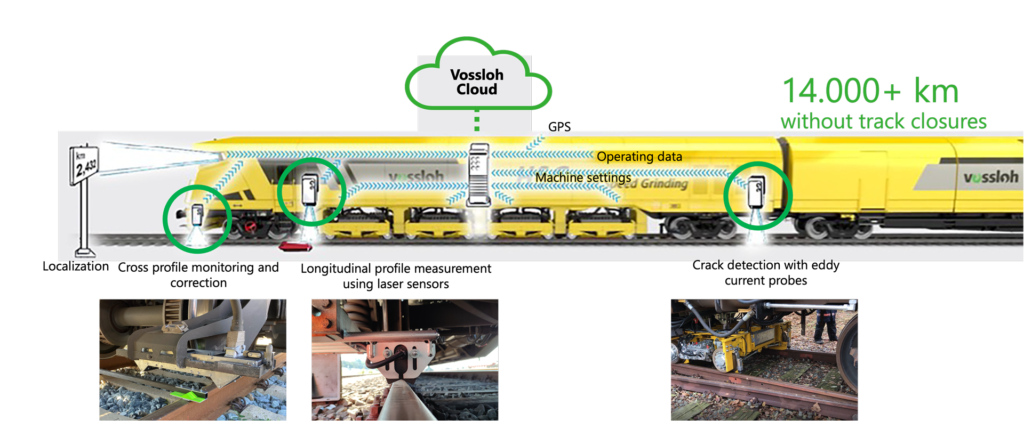

SENSE: Integrated sensor system detects the condition of the rail

- Measurement data enables optimal planning of our rail maintenance

- Knowing the actual condition of your own rail network is the key lever for intelligent and efficient rail maintenance.

- Therefore, the HSG smart grinding train has integrated measuring technology to carry out transverse and longitudinal profile measurements and is also equipped with a trolley for eddy current testing (for even more reliable crack prevention).

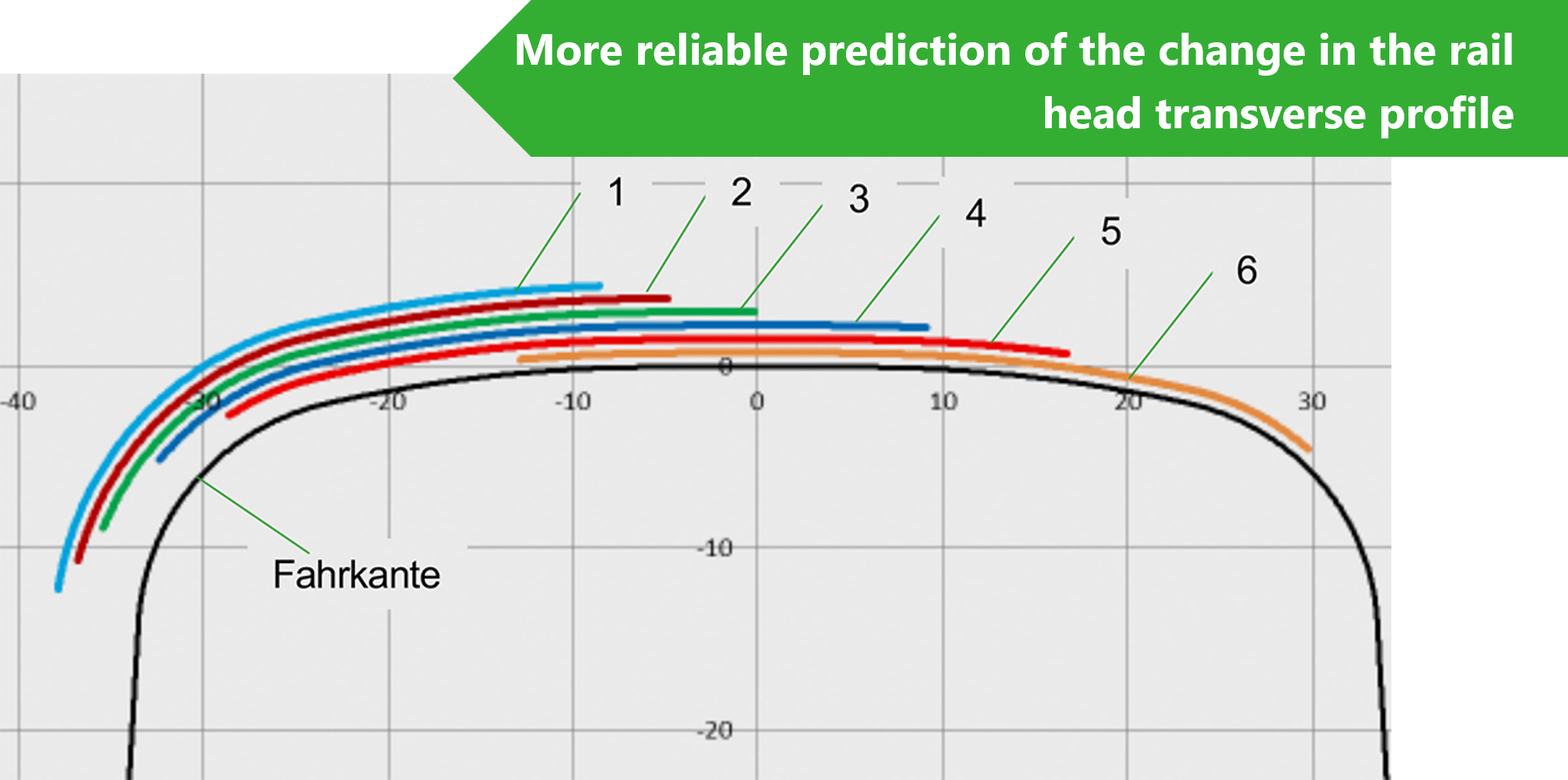

- The sensor technology works relatively autonomously and measures both rails simultaneously, making it possible to determine the track gauge. The wear reserve in the rail head can also be measured by means of transverse profile measurement.

- Measurements during a pass provide daily reports on the condition of the track

- Intelligent evaluation of measurement data

- Maintenance services specifically adapted to the needs of the track

- Interference reduction

- No further increase in milling needs -> equates to fewer track closures

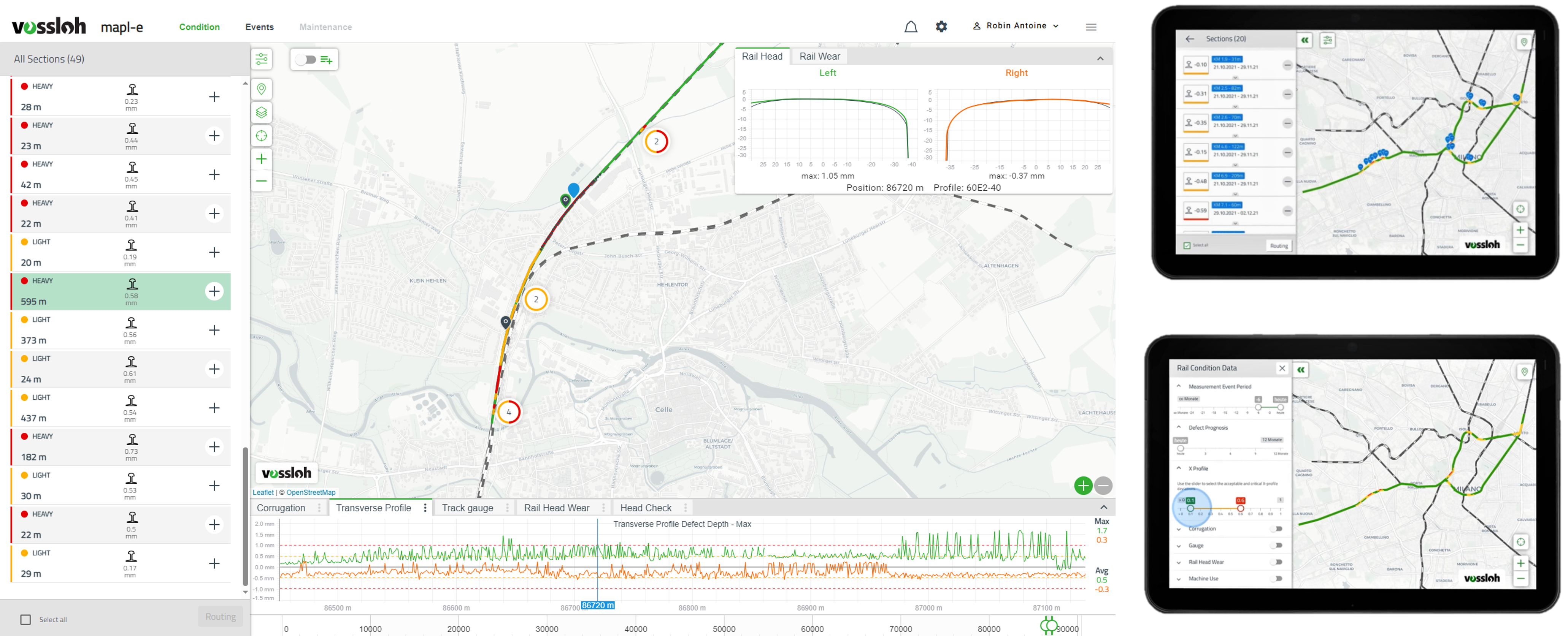

SEE: mapl-e simplifies planning & control processes

Solve: Condition- based grinding with the grinding track generator

- Answer to: HOW do I have to grind

- Based on the results from mapl-e and thanks to the new HSG grinding wheels, the sensor data is used to automatically select the grinding tracks during the subsequent grinding campaign with the help of the grinding track generator. This procedure enables both a targeted reaction to the detected condition of the cross profile and precise guidance of the grinding wheels along the running edge. In the following grinding cycle, the grinding facets are shifted from the tread to the running edge if necessary. Thanks to the elongated contact line, the grinding wheels remove brittle surfaces (hardened edge layer) as well as the beginnings of corrugations and slip waves.

- Use of data from the previous pass

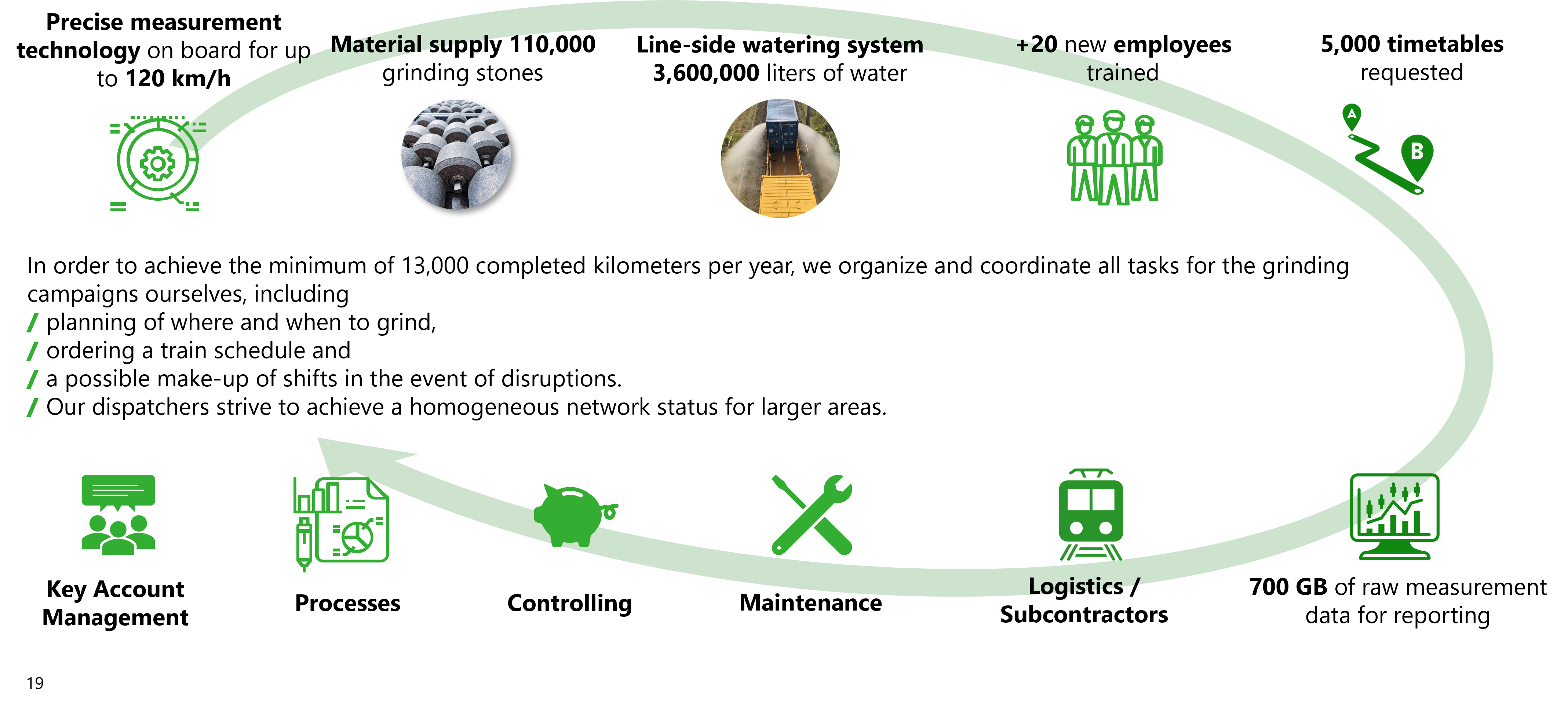

Availability:„Availability as a service“

From a service provider to a partner

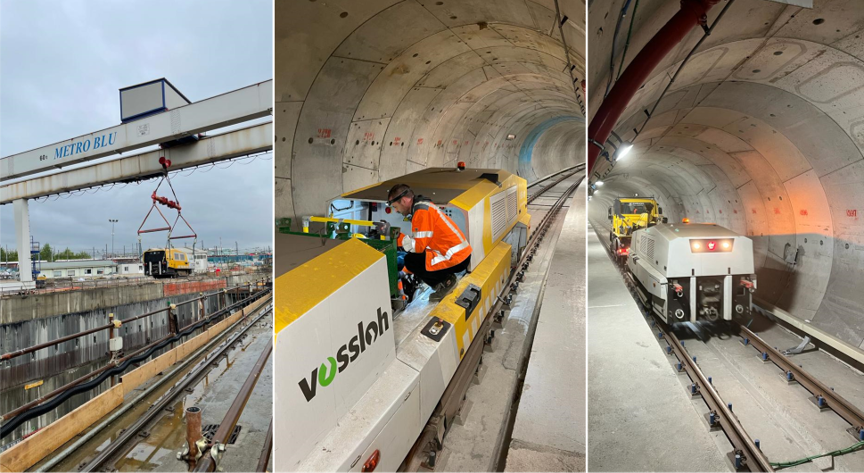

Alternatively, the compact HSG-city is available

Over 40 compact machines are in use worldwide with great success

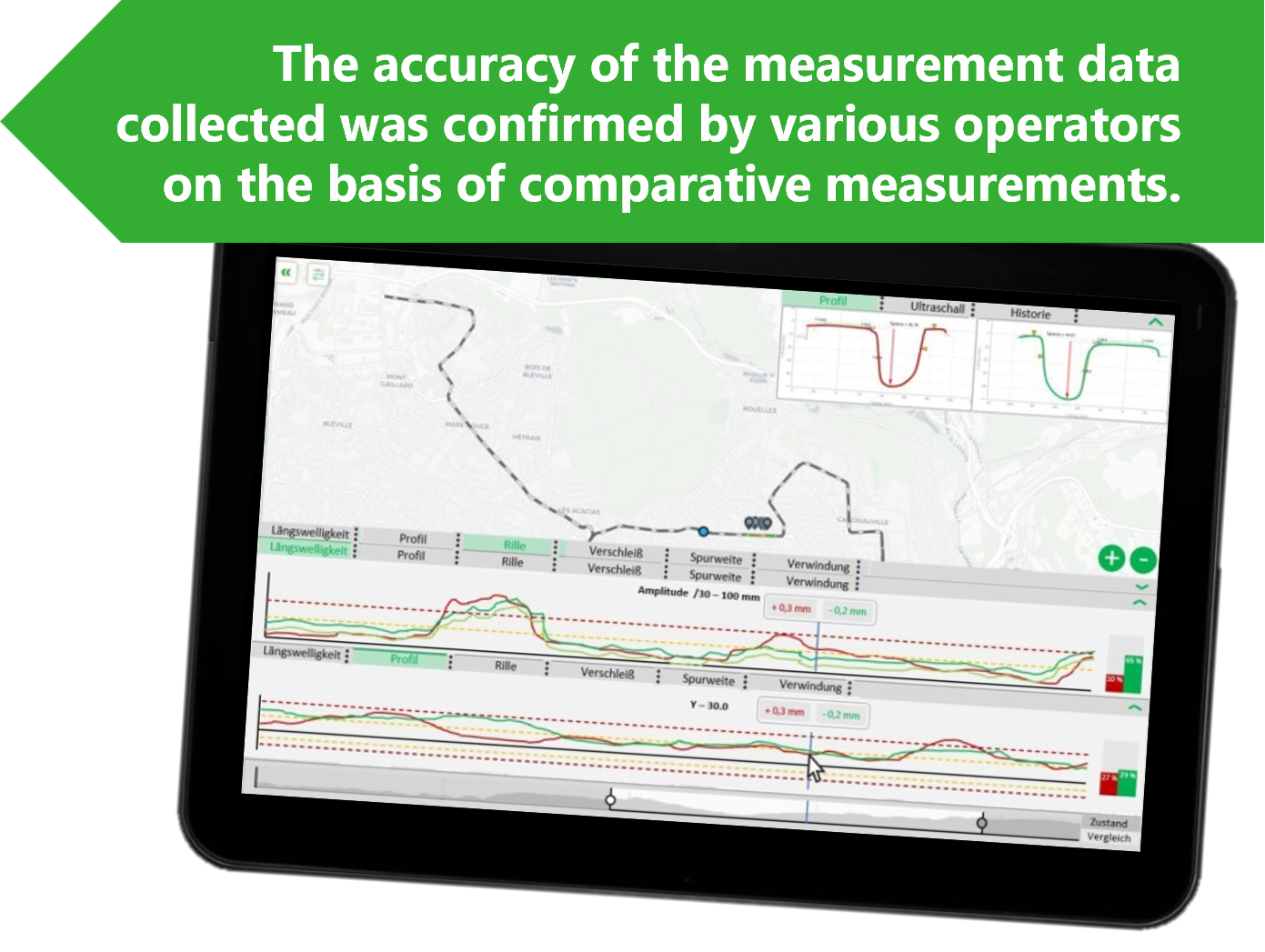

The HSG-city smart has been collecting condition data in several urban transport networks in Europe since 2021. More than 800 kilometers of data have been collected so far.

What does the smart HSG-city measure?

/ Position: GPS / Galileo ±5 m

/ Distance with odometer ±1 mm/m

/ Measuring computer in the central module for wireless operation / monitoring and automatic uploading of measurement data (WiFi / 4G)

/ Complete analysis of the cross profile:

/ Rail head deviation

/ Wear and tear

/ Groove depth (optional)

/ Track gauge

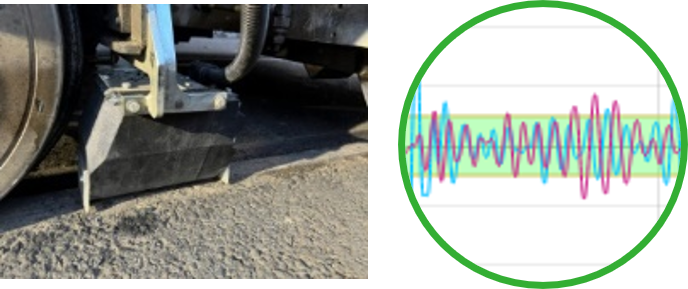

/ Longitudinal profile with corrugation sensor (1 measurement per mm; accuracy ±0.008 mm)

Effective corrugation removal in local traffic

Primary customer targets in Milan

Tram Network in Mailand

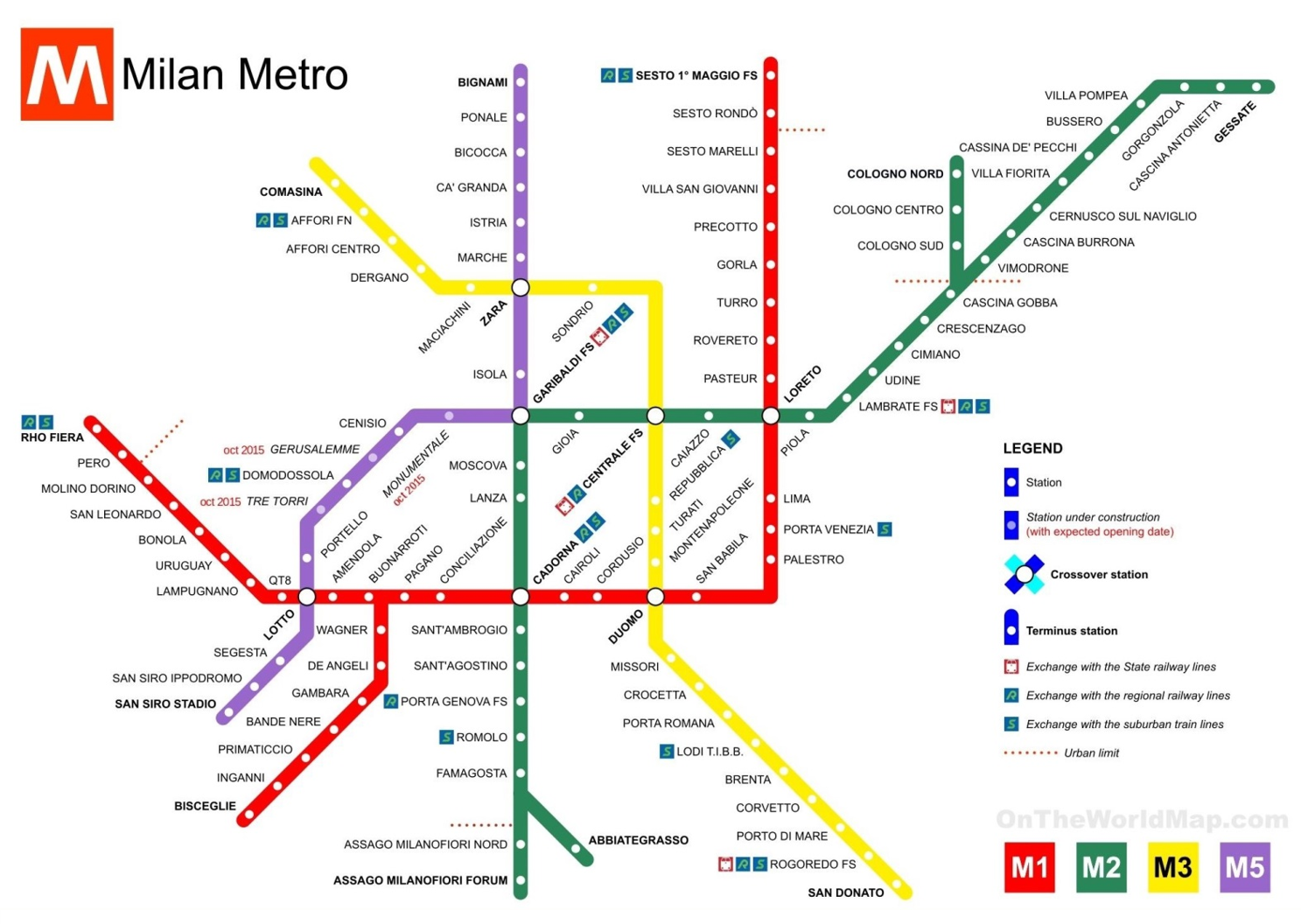

Lombard capital's metro

- In order to maintain an overview due to the dimensions of both networks and to minimize the flood of data from measurement results or to be able to use the knowledge gained more efficiently, ATM entered into a development partnership with Vossloh.

- ATM gave us the opportunity to intensively test both the new measurement technology at HSG-city smart and the evaluation and implementation of the data obtained in mapl-e.

- The agreement also covers the Metropolitana di Milano which comprises four lines that extend over 113 stations (78 of them underground) for about 120 kilometers. The Lombard capital’s metro network has been in operation since 1964 and will be expanded further in the coming years.

Regular measuring campaigns

In order to be able to use the special characteristic of the High Speed Grinding process – namely the high working speed of up to 60 km/h – also during the recording of the rail, the measurement of the longitudinal and transverse profile is carried out with the aid of laser scanning. The non-contact optical measurement system with fully integrated laser triangulation sensors also enables real-time data processing.

-

smart HSG-city captures rail & track

condition data without track possessions

Measurements currently performed by smart HSG-city:

- Complete transverse profile analysis:

- Rail head deviation

- Wear and tear

- In addition, ATM wanted a measurement of the groove depth in the tram network, which is also determined by laser scanning.

- Longitudinal profile/corrugations

- Track Gauge

- Track level and distortion

- Position & distance: All status data is recorded and located with meter precision. Vossloh brings various methods for unambiguous localization together. When the measurement is triggered, the odometer starts. In addition, global satellite navigation systems (GNSS) support the position determination.

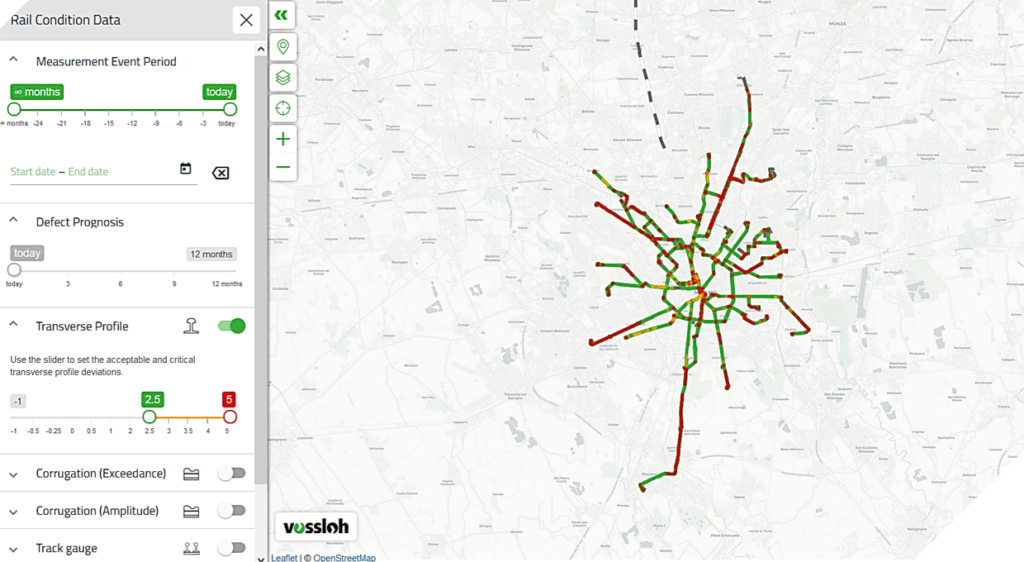

Data analysis – data visualization – data access

- For processing the huge data volume into intuitively understandable treatment proposals, the data are uploaded to the mapl-e platform after each measurement run. The data are stored in the cloud and retrievable from any terminal device.

- With mapl-e, we simplify all planning and control processes for the asset managers.

- The clear presentation & very easy operation provide quick access to the processed data.

- The rail condition is intuitively visualized in traffic light colors. This simplified evaluation into good, bad and critical is carried out via variable tolerance bands. In this way, asset managers can quickly and easily change important influencing variables or threshold values at any time and playfully test their effects on shift performance and costs.

- mapl-e subdivides the measured distance into several treatment sections – depending on the type and depth of the defect. So that asset managers

- obtain a complete overview

- can prioritize line sections to be treated &

- plan corresponding activities in a targeted way.

Grinding where necessary

- Since mapl-e is not limited to the display of measurement data, but evaluates different maintenance scenarios for the most suitable technology or rail processing machine by using complex algorithm sets at the push of a button and calculates the processing times as well as costs.

- Grinding work is carried out on the smart HSG-city at up to 60 km/h.

- In several passes, minor corrections of the transverse profile can be made by setting the grinding paths.

- Each rail machining is concluded with a measurement of the resulting transverse profile and an automatic documentation of the maintenance results.

- For safety reasons and in accordance with the rules and regulations, both the condition survey and the grinding take place in Milan during the nightly shutdown between 2:00 and 4:30 am.

- In order to be able to use the short time windows effectively, both measures are currently still being carried out in separate shifts. This ensures that, on the one hand, vibrations caused by the grinding process do not falsify measurements and, on the other hand, the necessary number of grinding passes can be performed.

- The tram network in particular has very tight curves. Radii of only 15 meters are not uncommon. For this reason, the approximately 20 to 30 kilometer measurement runs are carried out with a tram as traction vehicle, while grinding is done with a Unimog.

Benefits from regular measurement campaigns

To achieve a sufficient amount of data, we repeat this each quarter. In addition to the growing data quantity, initial findings on the development of tear & wear can be derived so that ATM gets a better feeling for its grinding strategy and can plan maintenance measures more proactively. With a more preventive maintenance approach in the mid term, ATM will also be able to optimize their maintenance budget at increased network availability.

- In summary, the enormous potential of our smart maintenance approach is seen on the customer side. The combination of HSG-city smart and mapl-e

- shortens network management and planning efforts;

- diagnostic data is available more quickly, and, above all,

- in a revolutionary simplified form.

- After the first statement – “it’s like touching the moon” – we have achieved a lot in the partnership of more than one year to organize rail maintenance more efficiently and to carry it out in a more targeted way.

„It’s like touching the moon”

Head check-Prevention within timetable

Functionality & USPs

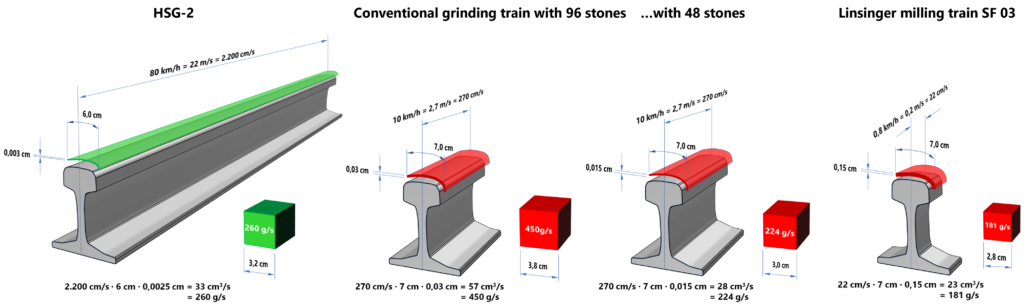

Grinding performance of the High Speed Grinding train

Compared to conventional rail processing machines

- Contrary to the opinion of some that the HSG only scratches along the steel

- the grinding stones ensure continuous, even and controlled material removal of 0.1-0.4 mm in several passes.

- The volume of metal removed at 260 g per second per rail is substantial.

- Up to 100 km grinding performance per shift possible.

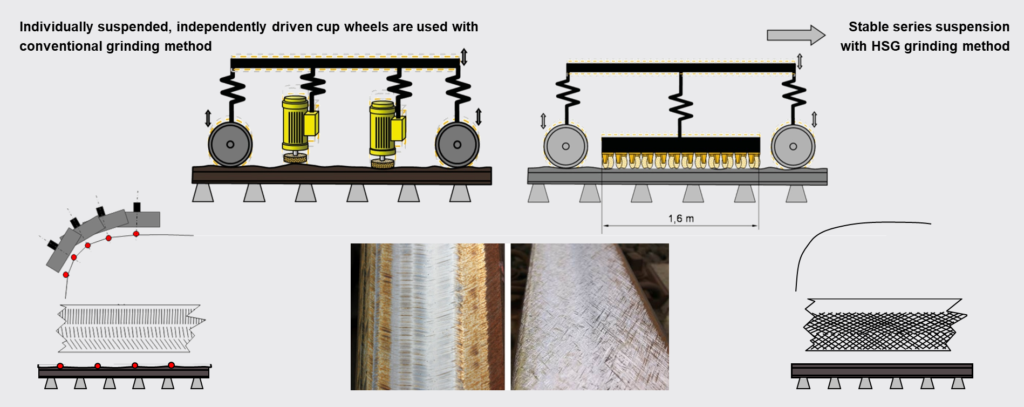

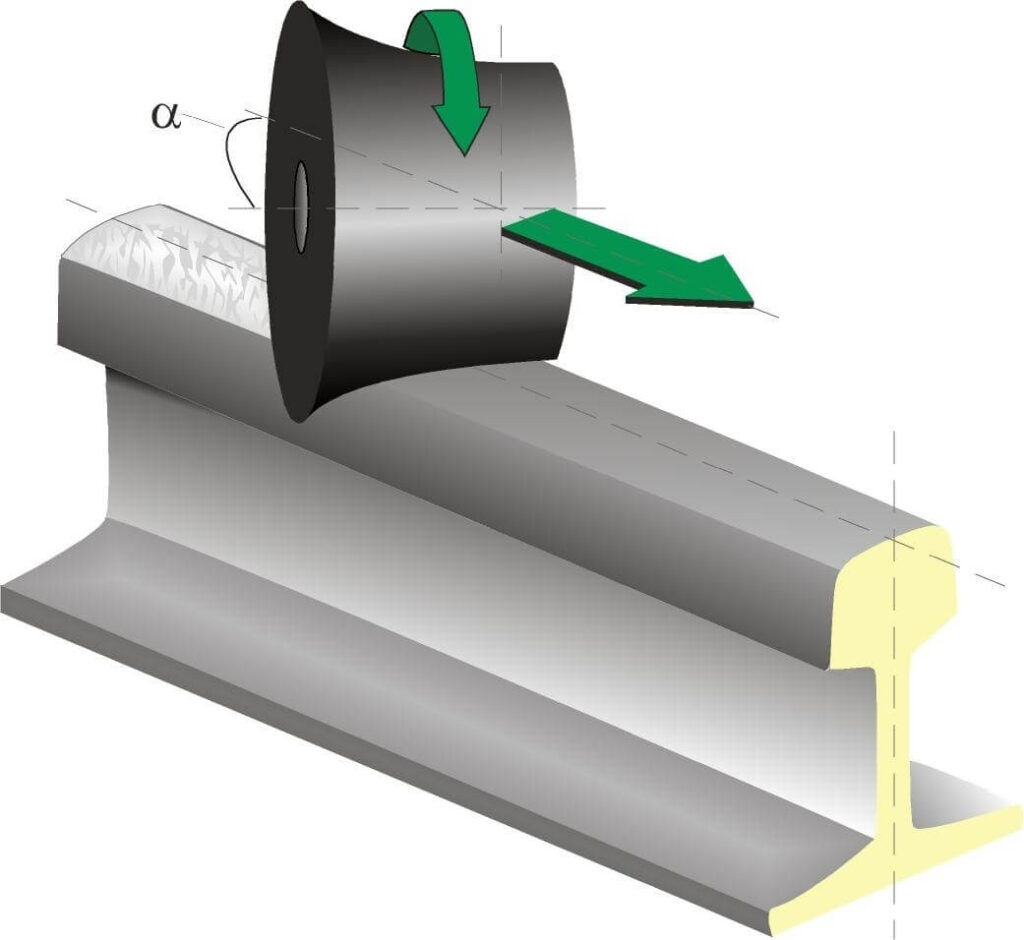

How the HSG grinding process works

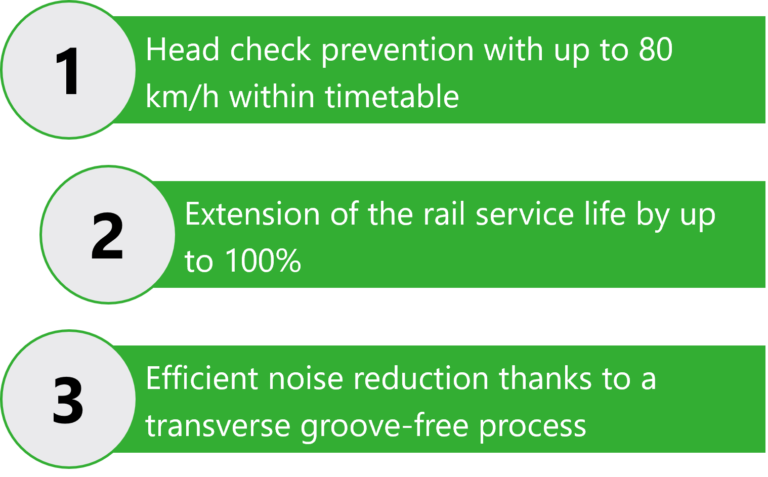

- The unique feature of this method specially for preventive grinding is the high grinding speed of up to 80 km/h, which makes it possible to grind in train mode inside the regular train timetable.

- HSG not only removes rail defects like head checks and corrugations, it also reliably prevents new defects from forming and thus extends the service life of rails by up to 100 %.

- Their angled orientation to the rail causes the peripheral grinding wheels to turn by themselves (passively driven)

- Due to the elelongated area of contact, the grinding wheels remove brittle surfaces (hardened surface layer) and the beginnings of corrugations and slip waves.

- The grinding intensity and output are determined by the speed of the traction vehicle and the grinding pressure.

- The aim is to remove 0.1 mm in three to ten passes.

- The existing rail profile is not altered because the grinding wheels take on the profile of the rails and not the other way around.

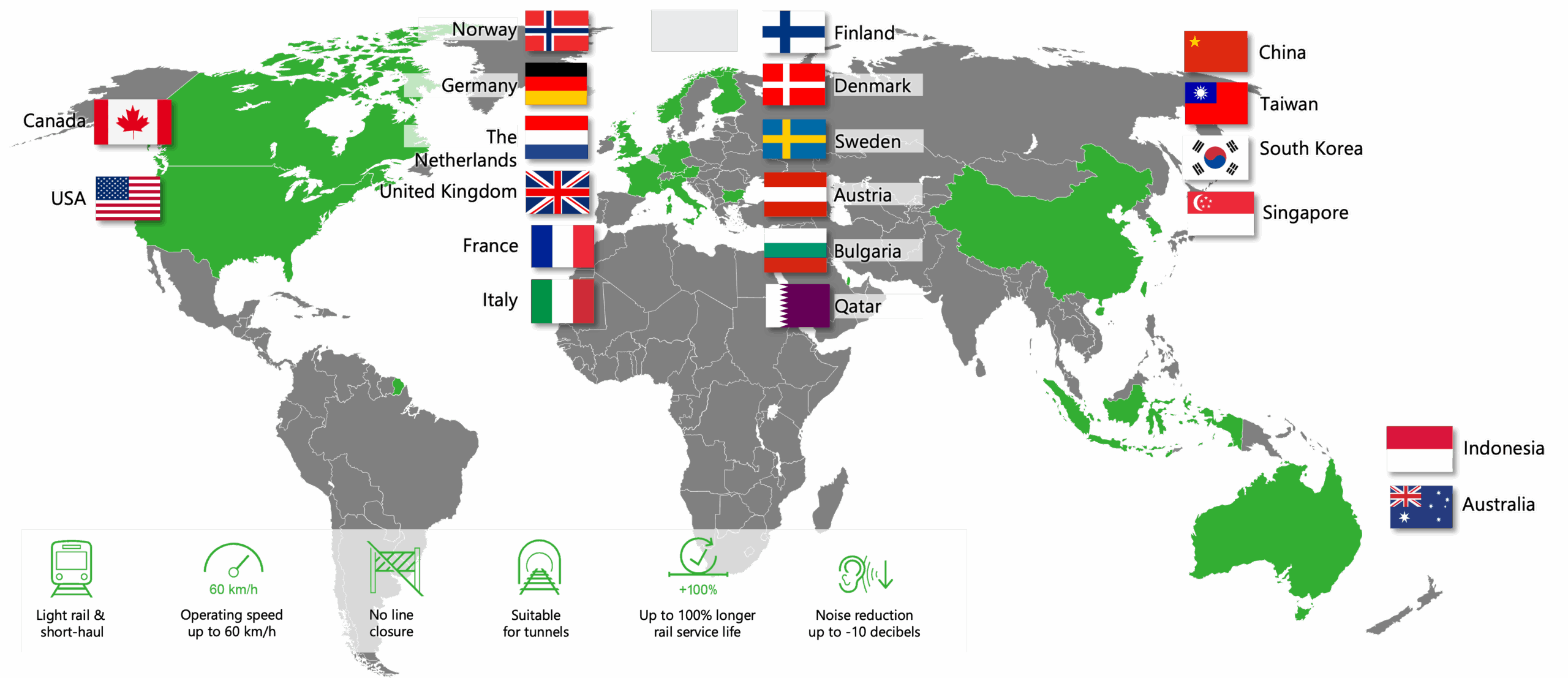

Now in more than 18 countries

- On almost all of DB’s main lines and on all the German high-speed lines

- Used on all PDLs in China for prevention, reprofiling and removing mill scale from newly-laid rails

- Officially recommended by the Chinese ministry for the maintenance of PDLs since 2019

- Since 2013, HSG-city has been used in numerous European and Asian cities and metropolises for removing corrugations and reducing noise.

Numerous applications

Application examples of HSG-city

- Removing the mill-scale that builds up during the manufacturing process considerably extends the rail‘s service life and forms the foundation for preventive rail maintenance

- Metal removal of 0.2 mm

- Lower surface roughness (Ra <6–10 µm) to prevent squat series

In purchasing an HSG-city, the tram network operator in the Finnish city of Tampere has gone with prevention right from the start. The network was opened for operations in the summer of 2021.

© Risto Eränen/Veho Oy Ab

A 4-db(A) reduction in the noise level was achieved in 13 passes at speeds of 18-20 km/h on a track section almost 8km long in Guangzhou.

- Fallen leaves in autumn leave a film of dirt that

- isolates e.g. switching equipment and thus interferes with switch activation,

- produces considerable noise emissions and

- lengthens the braking distance of the vehicles.

- Regular passes with the HSG-city safely removes the greasy residue and rules out potentially adverse effects.

- Improved traction thanks to the slightly roughened rail surface is a further plus.

Zero-emission grinding with HSG-city hybrid

Coupled to an electric traction vehicle, the three hybrid versions of the HSG-city carry out zero-emissions grinding on the Shenzhen Metro for the first time. A further advantage is that the combination only requires one operator. This enables either:

- a greater range,

- triple the output in just one pass, or

- a combination of rough and fine grinding wheels to perform the metal removal and the fine grinding in a single procedure.

In 2015, line 6 of the Beijing Metro became the first HSG-city project in China. Although the tracks had only been opened in December of 2014, heavy traffic had already caused severe corrugations to appear on the rails – particularly in curves with small radii. Rail defects, particularly slip waves, had formed, making it necessary to grind up to 0.36 mm off the rail surface.

The applications are numerous and range from removing mill scale from newly-laid rails to noise prevention and the removal of corrugations. We achieved a reduction in noise emissions of 4 db (A), for example, on the tram line in Guangzhou.