More capacity for Norway’s rail freight traffic

System W 30 for heavy haul applications on the Ofoten line from Narvik to Riksgränsen on the Norwegian-Swedish border

Customer: Bane Nor

Safe travel even under extreme conditions with temperatures down to -60 °C

System requirements: high axle loads of up to 35 t

Line: 43 km, single track, 50 % curves with a radius of < 500 m (min. R = 260 m)

Robust & durable fastening system, low maintenance requirements

According to the infrastructure operator Bane Nor, rail freight traffic on Norway’s rail network increased by 12 % in 2021 over the previous year. On several routes, the volume even grew by more than 20 %. But capacity constraints are becoming apparent on some lines; these constraints severely limit the potential for further growth.

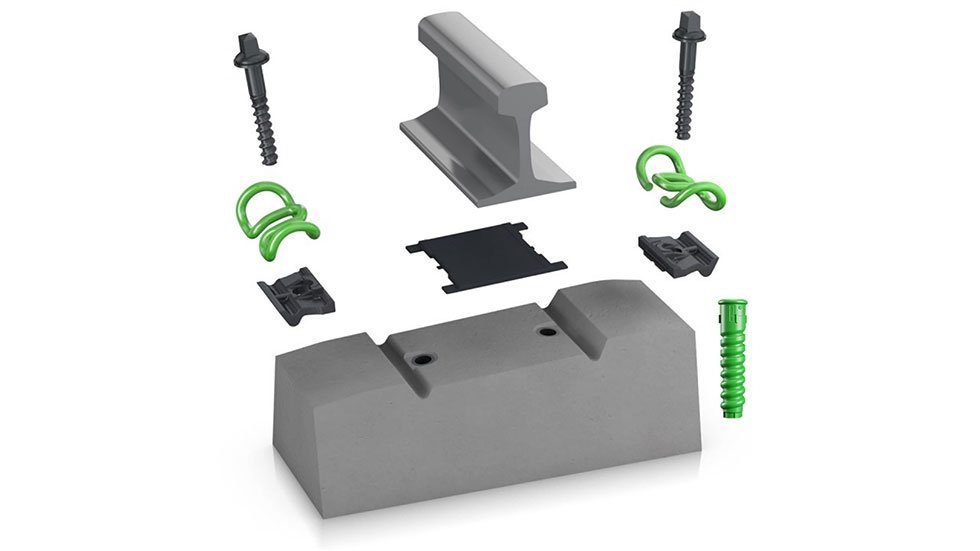

Our proposal: the W 30 fastening system for heavy haul applications - putting heavy haul transport safely on the rail

The elastic W 30 (HH) system is one of the most robust special fastening solution for heavy haul applications with axle loads of up to 35 t on ballasted track with concrete sleepers:

- protects the entire track superstructure against material fatigue

- provides stability even at high loads & in tight curves

- installation of a W system ensures high gauge accuracy

- modular design allows easy subsequent adjustment of the W-System in case of changing loads & requirements;

e.g. if elasticity requirements increase, the rail pad can easily be subsequently exchanged - relatively flat system structure: no risk of damage by passing snow ploughs

- diverse adjustment options of the system

×

Details on the components: System W 30 (HH)

- Larger diameter & the optimized geometry of the Skl 30 tension clamp provide high toe load, high dynamic fatigue strength and a high creep resistance > allow safe travel even under extreme conditions

- Long spring travel of Skl 30 > i.e., under load, the spring arms remain in contact with the rail foot & the rail is safely friction-locked

- Extreme temperature influences as well as acceleration and braking forces are safely absorbed by the creep resistance > dangerous fracture gaps are avoided

- Rail is protected against strong tilting under lateral load > plastic deformation of the outer spring arms is avoided

- Maintenance free & protected against corrosion by Vossloh protect

- Angled guide plates keep the rail in the track

- Rail pads made of TPU withstand high axle loads

- Screw-dowel combination NG ensures safe clamping & reduced loading

- In addition, the synthetic material used for rail pad, angled guide plates and screw dowel is electrically insulating – an additional insulator between tension clamp & rail is not required

Preassembly & replacement

- Preassembly of all fastening components possible

- At the site: place & clamp the rail Æ nothing gets lost

- Neutralization of the rail without removing fastening elements

- Replacement of all components possible, also including the dowel

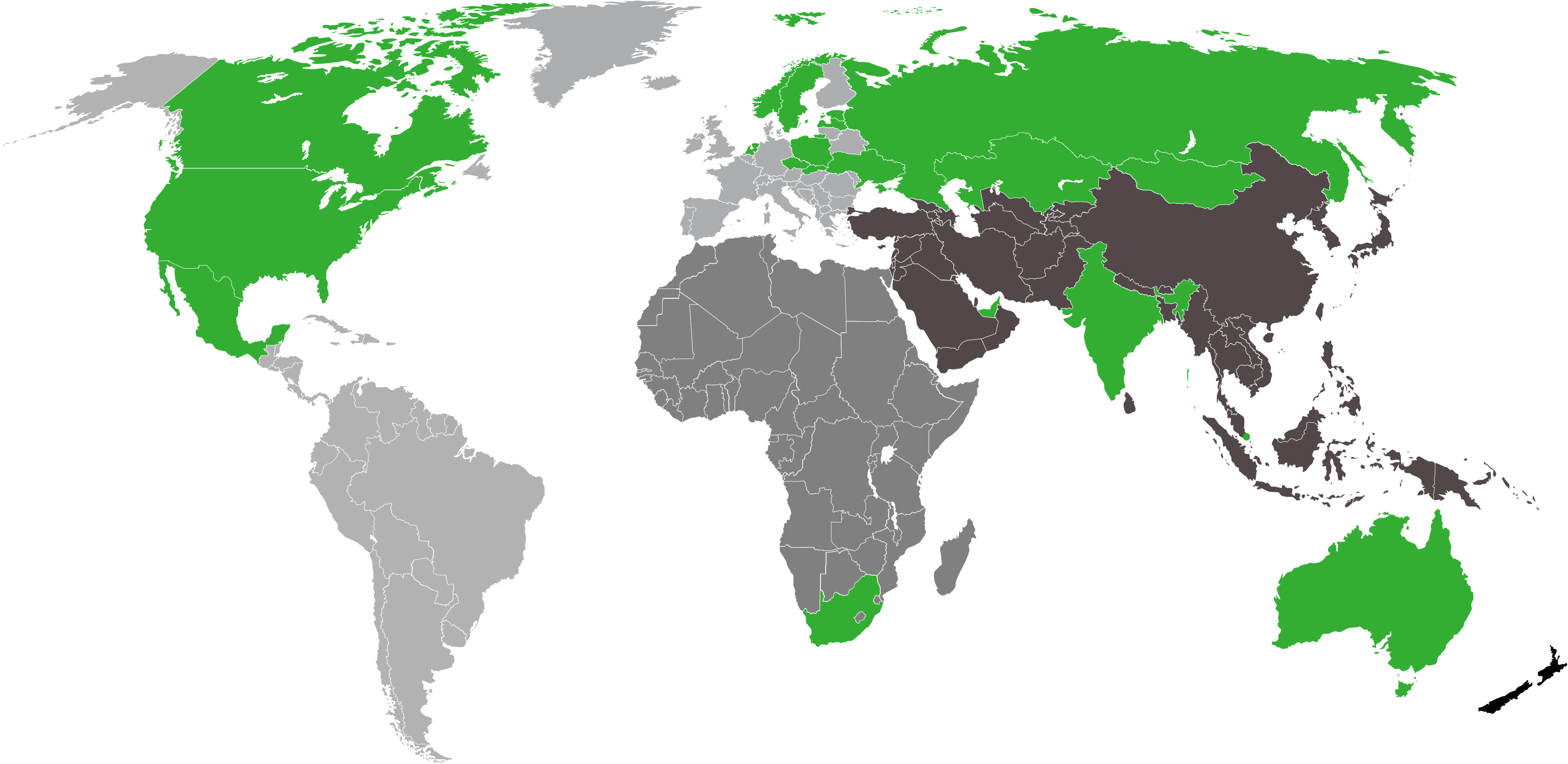

Global References: W 30 System Family

Standard system for heavy-duty traffic on concrete sleepers in the USA

X

Neue Eisenbahnstrecken von Etihad Rail in den Vereinigten Arabischen Emiraten

X

/ Total length: ~870 km (stage 1 & 2)

/ Total length: ~870 km (stage 1 & 2) / Stage 1 has been fully operational since January 2016

/ Passenger traffic: 200 km/h & 25 t Freight traffic: 120 km/h & 32 t

/ Challenges: environmental conditions & mixed traffic

Heavy-haul line in Mongolia

X

/ Total length: ~330 km

/ Total length: ~330 km / Demanding climatic conditions & challenging soil conditions

fastening points

0

of track

0

km

countries of service

in

0