Smart turnout heating for an environmental-friendly & cost saving power supply

Vossloh’s approach:

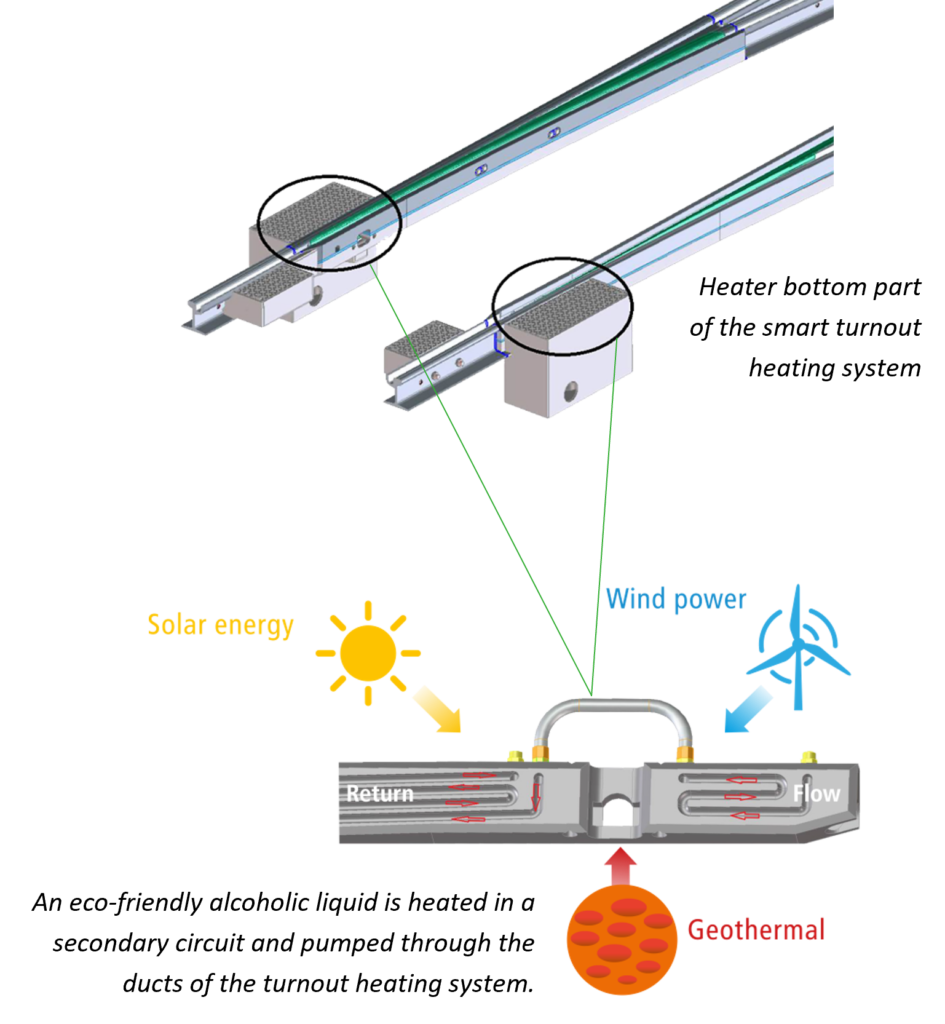

- To prevent switch blades from freezing or accumulating snow, Vossloh uses the steel’s thermal capacity in a welded monobloc sandwich design.

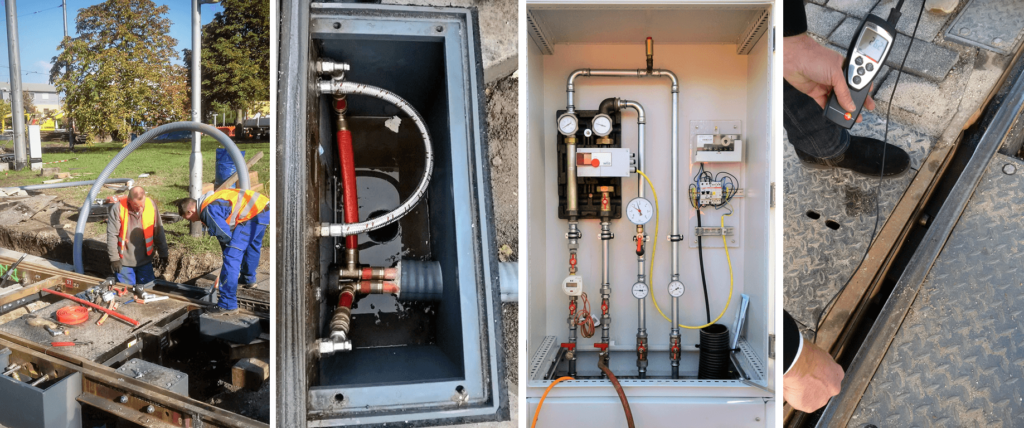

- To allow on-demand heating in case of snow or minus temperatures, additional instrumentation is installed for measuring precipitation along with air and rail temperatures, as well as the control system, housed in a switch cabinet, which enables the complex heating system to kick in only when the conditions so require.

- It can be adapted via a heat exchanger to any renewable power source (aerothermal, geothermal, hydrothermal, solar panels, waste heat from local buildings/industries).

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

Lifecycle energy consumption of turnouts:

- Over a service life of 20 years, electric heating costs for grooved rails or R190 Vignole turnouts are equivalent to between approx. 8% and 25% of the entire LCC.

- Once the investment for a regenerative energy-based heating system has been made, the electricity costs are reduced to a mere €15 to €20 per year – only 3% to 4% of energy costs of traditional systems.