For maximizing the track availability, turnouts are the ideal gateway for the continuous sensor-based collection of condition data. Since turnouts are not only the point where tracks converge or diverge but also a hub for various signalling and control systems, the information content of the data collected here is especially high. In addition, data-driven predictive maintenance solutions for turnouts promise a clearly noticeable effect very quickly.

Since Vossloh is an expert in asset design and maintenance, in telecommunication and in sensor-based railway monitoring, the system architecture ensures that all data communication is encrypted according to the cyber security standard ISO 27001, using standard protocols such as MQTT and OPC-UA.

With our data-driven predictive maintenance solutions, Vossloh is:

- reducing maintenance costs for point machines and turnouts,

- extending their useful life and

- improving the availability of the whole rail infrastructure.

In this regard, it is clearly an advantage that Vossloh accompanies assets all over the world through their life cycle and uses its experience gained in other international projects for new markets or customer projects. As an in-demand switch specialist for all railway lines, Vossloh has a leading position in all core markets worldwide. Alongside the development of new turnout systems with intelligent control systems, we also help customers to modernize existing switch systems, thereby improving operation and achieving lower maintenance costs for the operator. This is where our decades of expertise in the holistic interaction of proven drive, locking and monitoring products as well as reliable detection systems with remote monitoring technology for preventive maintenance comes into play.

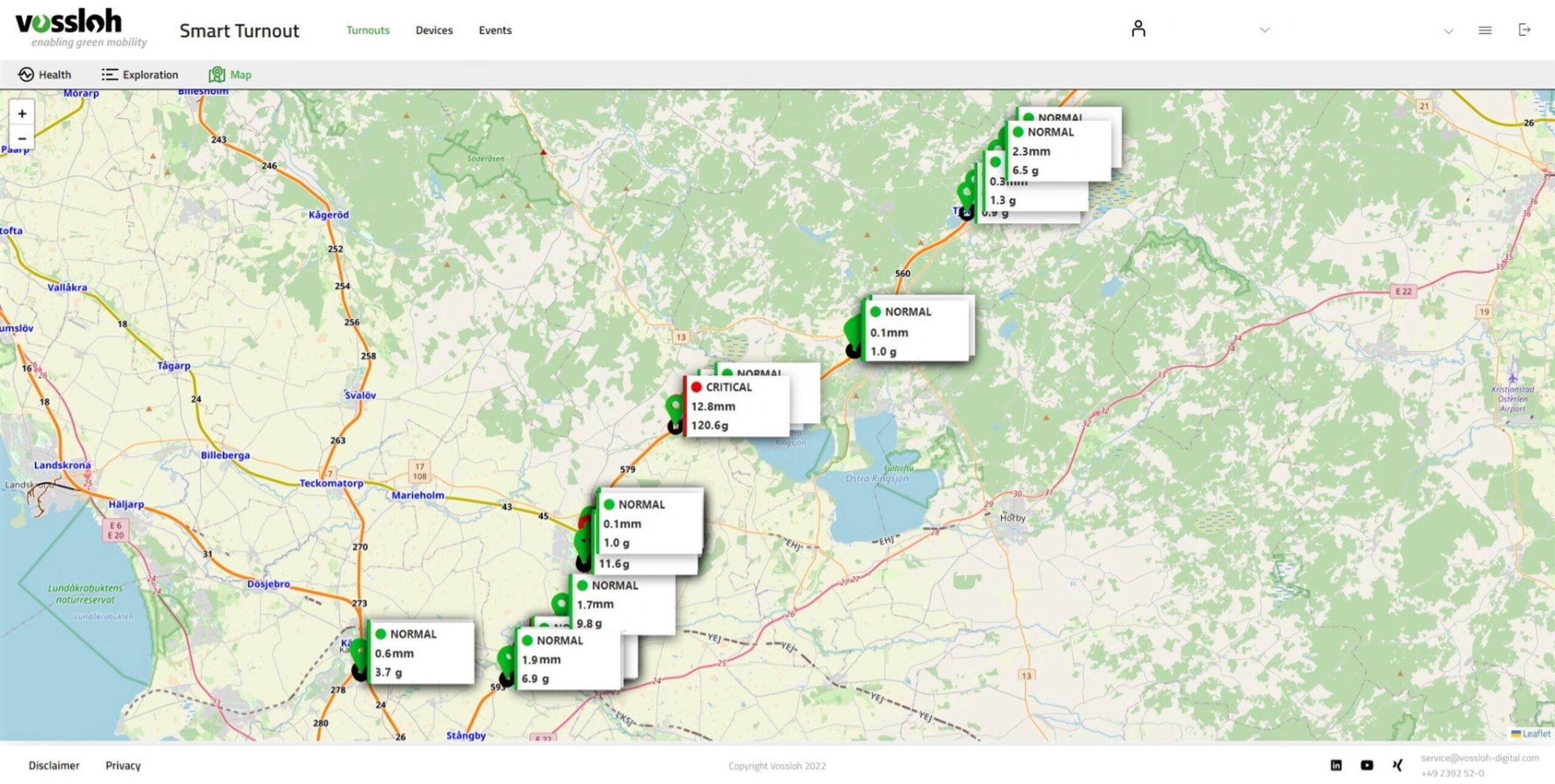

Smart Turnout

is your preferred tool when a network-wide monitoring of turnouts or track sections is required by managing a sensor fleet. Vossloh is responsible for:

- sensor selection, logistics & maintenance

- big data handling & analyzing for providing

- recommendations to optimize maintenance actions & regimes

Smart Monitoring Vossloh

enables a targeted function monitoring of individual systems with the aim of extending the life of turnout systems.

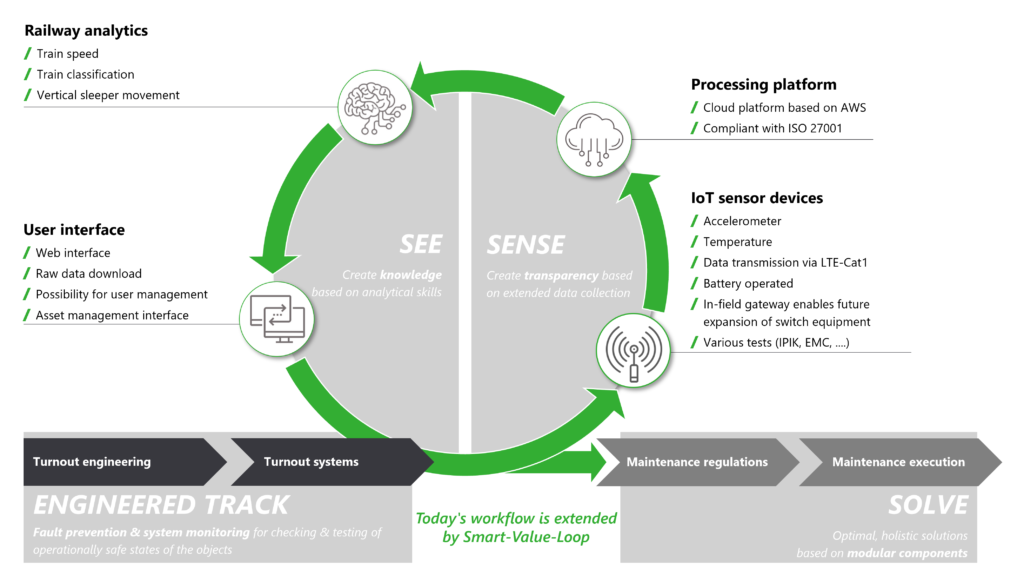

Vossloh’s approach Sense – See – Solve

Smart approach to get the big picture

Sensor-based turnout monitoring with a large fleet of sensors distributed across the entire network implies the following aspects:

- ensuring the continuous functionality of the sensors incl. the selection of suitable sensors for the corresponding condition survey

- a logistic concept (initial assembly, maintenance & replacement)

- handling of large amounts of data

- using artificial intelligence-based algorithms to convert the measured data into appropriate derive recommendations for action

Smart Turnout: Long-term, large-scale observation of the infrastructure asset

The data-driven asset management enables an active maintenance management with resilient planning and control at the same time. Qualitative KPIs are the foundation for performance acceptance and actual cost management.

User benefits

- Optimized maintenance cycles:

- Asset insight from automatic data-driven analytics (based on infrastructure expert knowledge)

- Proactive maintenance management

- 24/7 online monitoring of turnout asset:

- Data available with time stamp: vertical displacement, turnout vibration, train type & speed, total number of trains

- Asset status indicator & automatic alarms

- Asset monitoring device fleet management

- Ease of implementation of the sensor & gateway (quick installation)

- Wireless connectivity & cloud based data management and visualization

In order to detect in particular sleeper heights in switches in good time before maintenance limits are reached and trains can only run slowly or not at all, the comprehensive and continuous monitoring of strategically important turnouts in the network enables asset managers to:

- detect in particular asymmetric support under sleepers in good time,

- derive the right limit values and thus to

- revise the maintenance specifications in the medium term.

The sensor boxes at the sleeper, developed to Vossloh specifications, continuously record vibrations and temperatures in the track.

The monitoring system is designed for speeds of 60 to 230 km/h with measurements between -20 and 35° C outdoor temperature.

Connected remotely to an IoT device – a gateway that automatically transmits data via the mobile network to the cloud-based platform Vossloh connect. There the data is analyzed, evaluated and the results displayed.

Focus on track availability

- Optimized maintenance cycles:

- Detect turnout asymmetry before maintenance limits

- Anticipate evolution of degradation & give a support to prioritize maintenance

- Revise the maintenance specifications in the medium term

- Increase asset lifespan by ensuring on time intervention

- Confirm & check the quality of maintenance works (e.g. tamping works) by checking the return to nominal condition

SMV

- Tracking the wear & tear of infrastructure assets

- Analyzing the necessity & quality of maintenance measures

- Planning condition-based maintenance

Smart Monitoring Vossloh (SMV) enables operators to solve problems and adjust maintenance rules accordingly in a targeted manner:

- Understanding exactly the overall behavior of the track, wear circumstances of infrastructure assets & the cause of failures

- More targeted planning of condition-based maintenance and repair measures

- Time saving & safety for the operators (reduced inspections on-site and less manual measurements)

On track along the French high-speed line SEA

Since commissioning the French high-speed line Sud Europe Atlantique (SEA) in July 2017, our customer MESEA has been responsible for maintenance and operation of the 302-kilometer line from Tours to Bordeaux.

- In consultation with the operator, the Vossloh team used internally developed monitoring systems to record rail temperature, air temperature, air humidity, vertical position of the engine mount, and vibration behavior during each train pass. In a second step, the train’s speed was added to the data in order to better interpret the information.

- After this investigation phase the team was able to describe the phenomena responsible for large amplitude movements in the turnout system. To avoid such occurrences in future, we set up the appropriate maintenance scheme.

- Today, eleven of our monitoring systems are installed on the SEA, which can monitor 42 actuators.

The SMV developed by Vossloh meets our expectations to monitoring the degradation of our facilities and allows us to analyze the relevance and quality of our maintenance interventions. In addition, the prediction with thresholds allows us to schedule conditional maintenance operations in a targeted manner. This device helps to limit the premature aging of the turnouts.

Denis Herlem, Technical Expert for Turnouts, MESEA