One Vossloh turnout project: in Montreal

In a suburb of Montreal, the rail infrastructure of an existing yard was renewed. The previous tracks embedded in asphalt were to be replaced by ballasted tracks. The earlier rail profile 100RA was changed to 115RE.

Additional challenge: turnouts are equipped with precast concrete panels for rubber-tyre vehicles to run on top. Moreover, the tracks will be used by vehicles of very different types with a total of 16 different wheel profiles.

Delivery: six short Tg1/5 turnouts on Engineered Polymer Sleeper (EPS), each of which required a customized footprint because of the nested arrangement. Tailored floor plans for each turnout and special metal cases were developed that allow a passing with rubber tyres and facilitate the access for maintenance. The cast manganese steel crossings were adapted to the wheel profiles so that even in case of an impaired traffic (flat tyre), a safe operation would be ensured.

The first turnout completely fitted to the EPS was accepted by the customer in the factory; the subsequent acceptances were performed via Remote Live Stream. For the transport, the turnouts were fully coated.

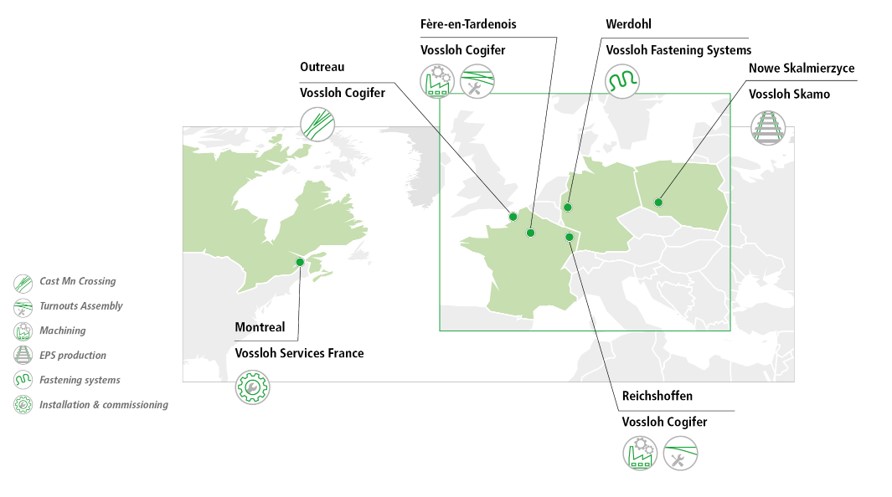

The consignment was delivered by ocean freight to the site in Montreal where the installation and commissioning were completed. This marked the successful closure of a truly international Vossloh project. While the EPS for the turnouts came from the Vossloh Skamo factory in Nowe Skalmierzyce in Poland, the manganese steel crossings were cast in the foundry in Outreau, turnouts manufactured in Reichshoffen, and all these components were finally brought together in Fère-en-Tardenois (all in France). The installation in Monteral started mid July 2024 with the assistance of Vossloh Service France. For its customers, Vossloh is a one-stop shop for turnout systems on composite sleepers – a perfect match.