HotSpot milling: Vossloh's MillingXpress

×

Pioneer for a new market segment

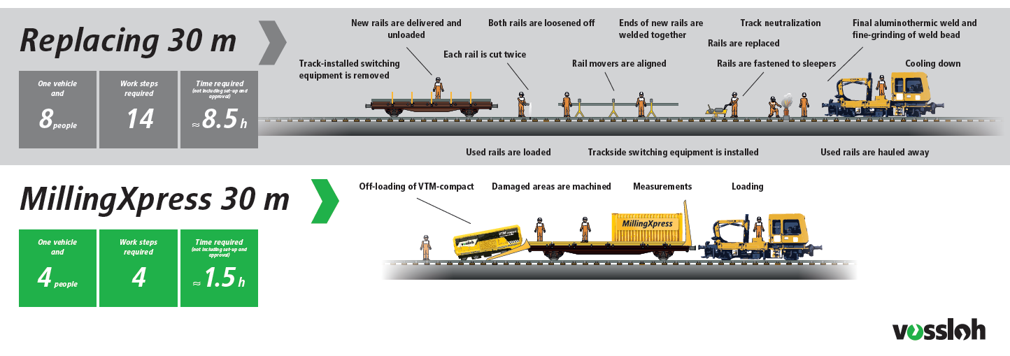

Instead of the time-consuming process of replacing rails in selected spots, we offer a comparatively simple and favorable alternative with our VTM-compact as the MillingXpress. Thanks to its high removal rate, the compact milling machine can be used very flexibly.

Tremendous removal rate

- Up to 2 mm per machining pass

- Correction of severe rail defects

- Improved cutting process & more precision when removing material thanks to up-cut milling method

- Rails are laser-scanned for pinpoint accuracy when lowering the tool onto the rail

- Milling zone:+5° and -70°

Universally applicable

- Ideal for short track sections, light rail or industrial rail facilities

- Perfect for smaller areas requiring intensive machining such as level crossings, tight curves and start/stop areas

- Suitable for the most diverse range of track construction types and all the common loading gauges thanks to its compact design

- Any track gauge can be realized, no matter how rare or unusual it is. From meter gauge to standard gauge and everything “in between” is no problem with the VTM-compact.

- Does not interfere with level crossings, and no dismantling of track signaling and switching equipment is required

100% free of dust and sparks

- Reaons for “milling only”:

- Rails machined completely spark-free in high-fire risk areas (e.g. In the petrochemical or wood-processing industries as well as tunnels and bridges, or during extremely dry periods)

- Improved traction when starting form a standstill and braking

Simple logistics

- Dimensions of a 20-foot container (TEU)

- Numerous transport and loading options:

- Transport by low loader or flat car to the site of operation

- Alternative feeding into the construction track by rail with any kind of traction vehicle

- Easy on-railing at the site using a specially designed carrier via a hydraulic ramp (if the track is sufficiently long) or by crane

- Height-adjustable coupling

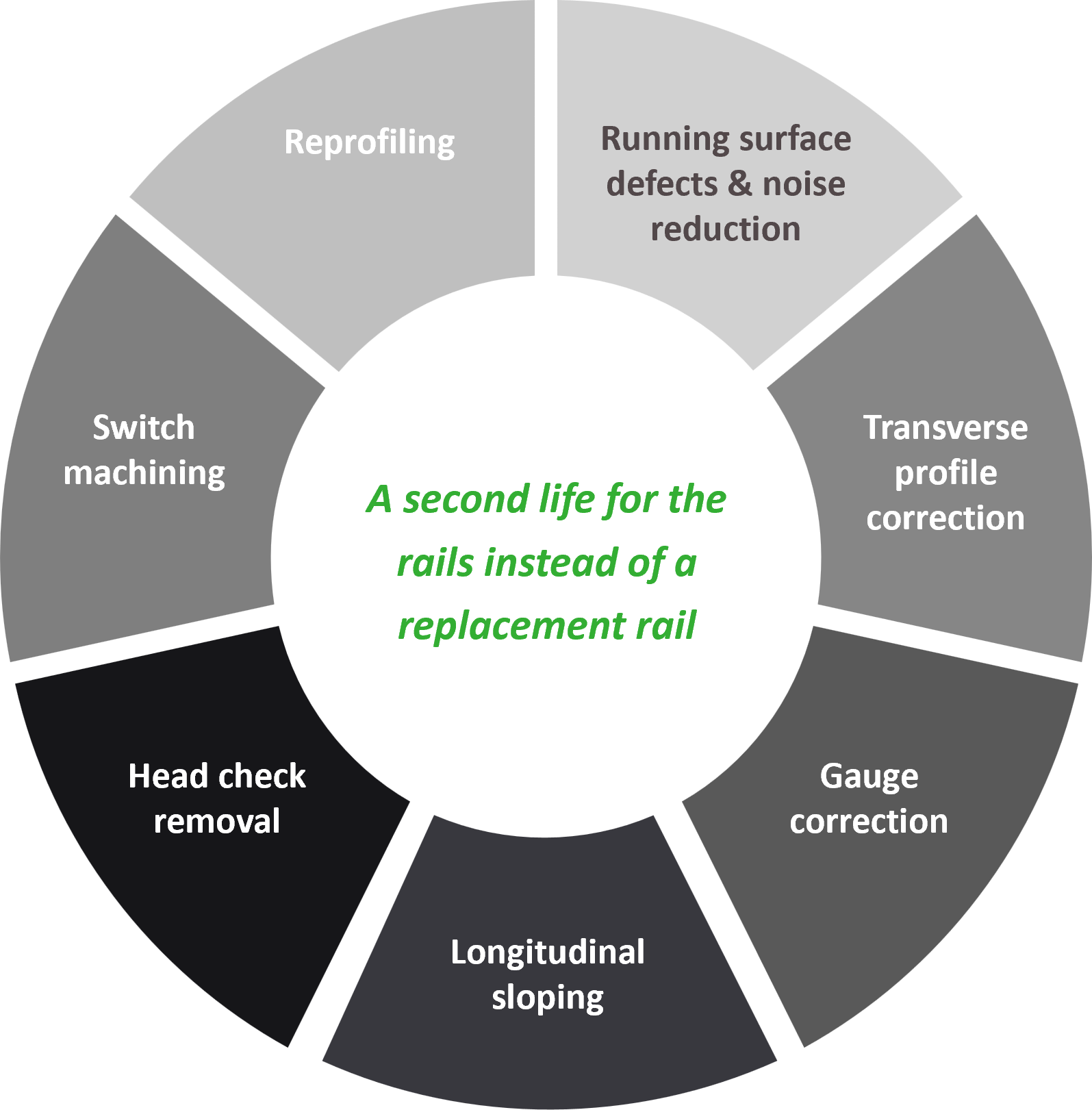

Corrective applications

Reference: Toronto

Rapid transit lines with speeds of up to 145 km/h between Toronto city center & airport

approx. 23.5 km long, double-track line with high capacity utilization

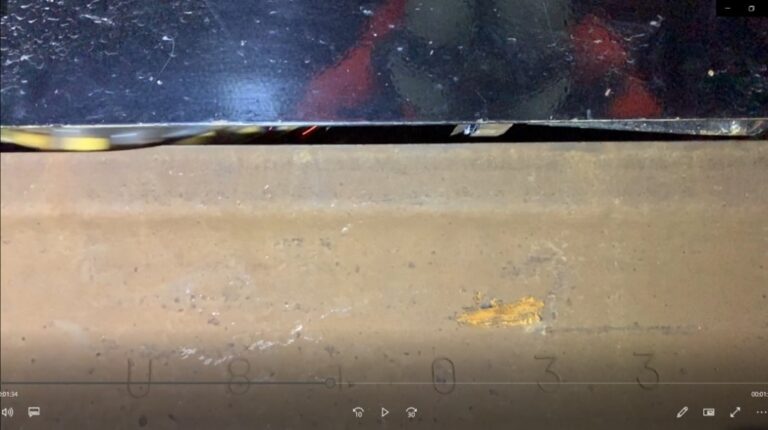

Particularly severe rolling contact fatigue faults on a 2.4 km long section

Measurements, analysis of defects, milling processing

After a total of 24 short night shifts, the route has been declared faultless again

Restoration of track evenness

Modetrans factory hall in Poznan, Poland

Reprofiling of 100 m of track in the Modetrans workshop

The mine railway used for the maintenance of rail vehicles showed considerable differences in height

To compensate for this, 8 mm of track was removed

Elimination of contact fatigue & restoration of the transverse profile

Removal of corrugations & strong irregularities in the longitudinal profile

Correction of the track narrowing

Maintenance at the Barmbek depot of Hamburger Hochbahn AG

Maintenance of the tracks at the Hamburger Hochbahn depot in Barmbek

Track narrowing: 1,417 mm (in places)

6 tracks were affected and had to be brought to a track gauge of 1,435 mm

3 shifts were necessary

The alternative would have been a cost-intensive removal and reinstallation of the tracks

The customer was very satisfied with the quick and easy solution to the problem