SoniQ Rail Explorer: Ultrasonic Inspection System

Objectives & applications

- Non-destructive material testing to detect & localize operations-related irregularities inside the rail in just one pass

- Manually-guided rail tester for pinpointing flaws and for regular inspections of short track sections, switches, crossing, level crossings and railway stations

- Enables condition monitoring of cast manganese steel crossings for the first time. The manual probes developed in collaboration with UltraRS detect discontinuities inside the manganese cast intersection to a depth of at least 60 mm below the running surface.

- Does not interfere with trackside signaling & switching equipment

- Software supports various flange rail profiles

- For all track gauges

- Development & manufacture based on the applicable standards and directives (DIN EN ISO 12668-1, ISO 22232-1, DIN EN 16729-1:2016, DIN EN ISO / IEC 9001) and our experience with numerous ultrasonic testing systems in the railway industry

read more

read less

Product Highlights

Ergonomic

- Balanced weight distribution

- Center of mass located in the middle

- Very easy to carry

Safety

- Does not interfere with track signaling & switching equipment

- Attestation from DB Systemtechnik

Sustainability

- Optimized couplant use

- Regulated valve operation and distribution by brushes

- Battery containing individually replaceable conventional lithium-ion cells

Reliability

- Hardware and software from the same source

- Designed and manufactured in Germany

Flexibility

- Customizable user interface

- Modular system

- Automatic rail height detection

- Gain adjustment without changing the DAC curve’s characteristics

- Can be integrated into all asset management systems

Data-oriented

- Optional storage of raw data

- Volume scan of all the raw data – signals displayed depend on the gate settings (slider)

Future-proof

- AI-compatible software

- AR for upgraded display options

- Inspects both sides of the rail

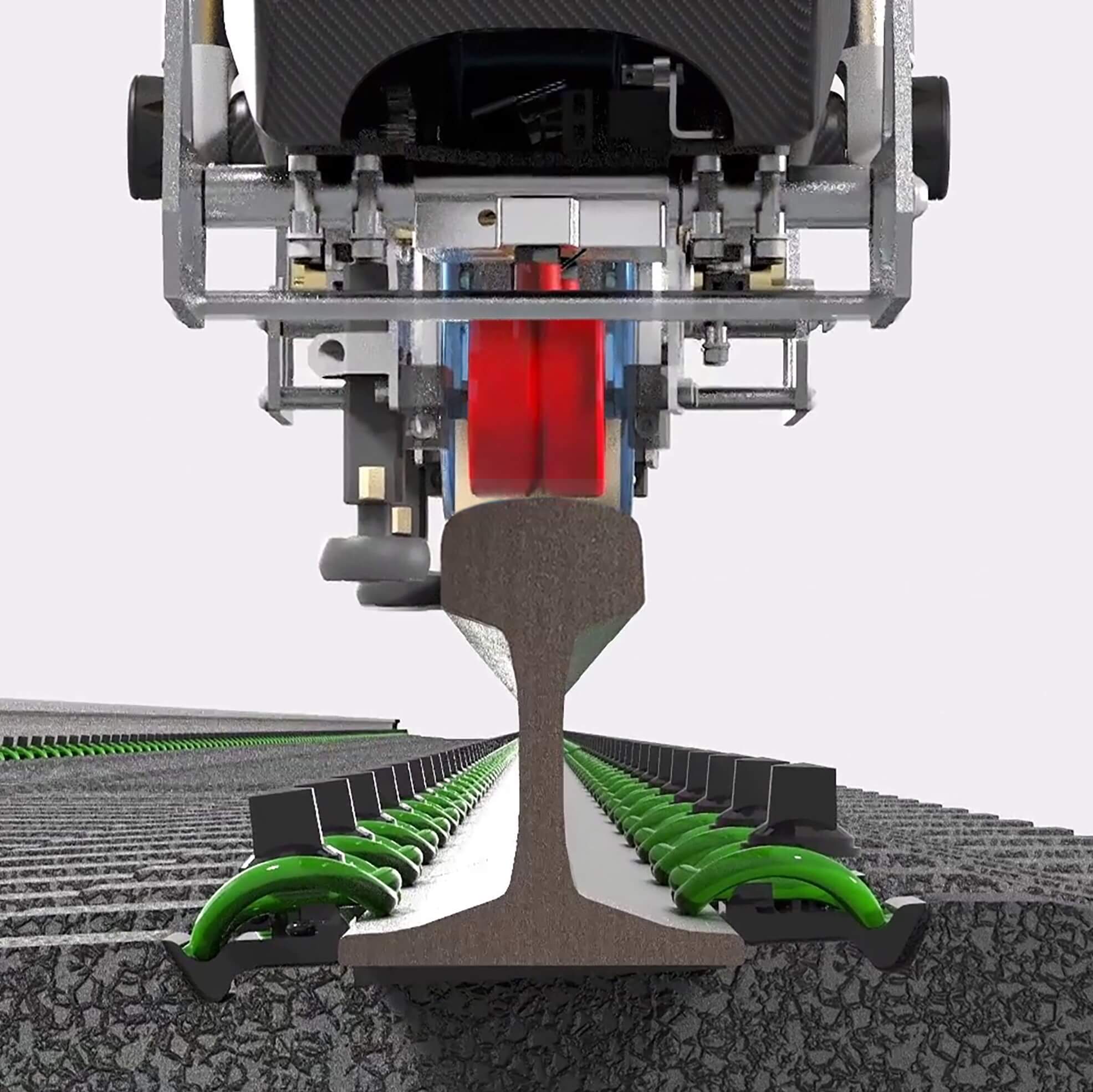

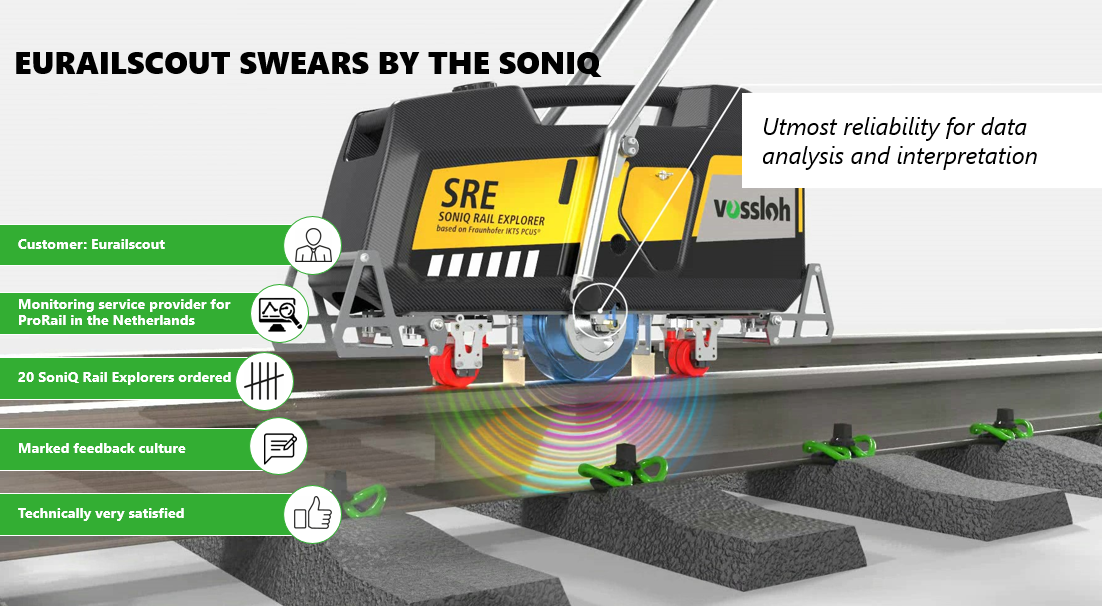

Ultrasonic inspection system

- Inspecting from as close as one millimeter, the nine probes in the test wheel capture an accurate picture of the rail‘s condition at an inspection speed of 3 km/h.

- In addition to the base and web of the rail, the nine probes in the ultrasonic test wheel cover nearly 100% of the rail head, reliably detecting reflectors from volumetric defects 5 mm below the surface of the rail on both the gauge corner and field sides.

- Linked to an encoder (incremental distance marker) for positioning accurate to the millimeter.

- Guide system ensures that the probes sound the rail from the best possible position (Important: the waves from the vertical probe must go through the rail’s web).

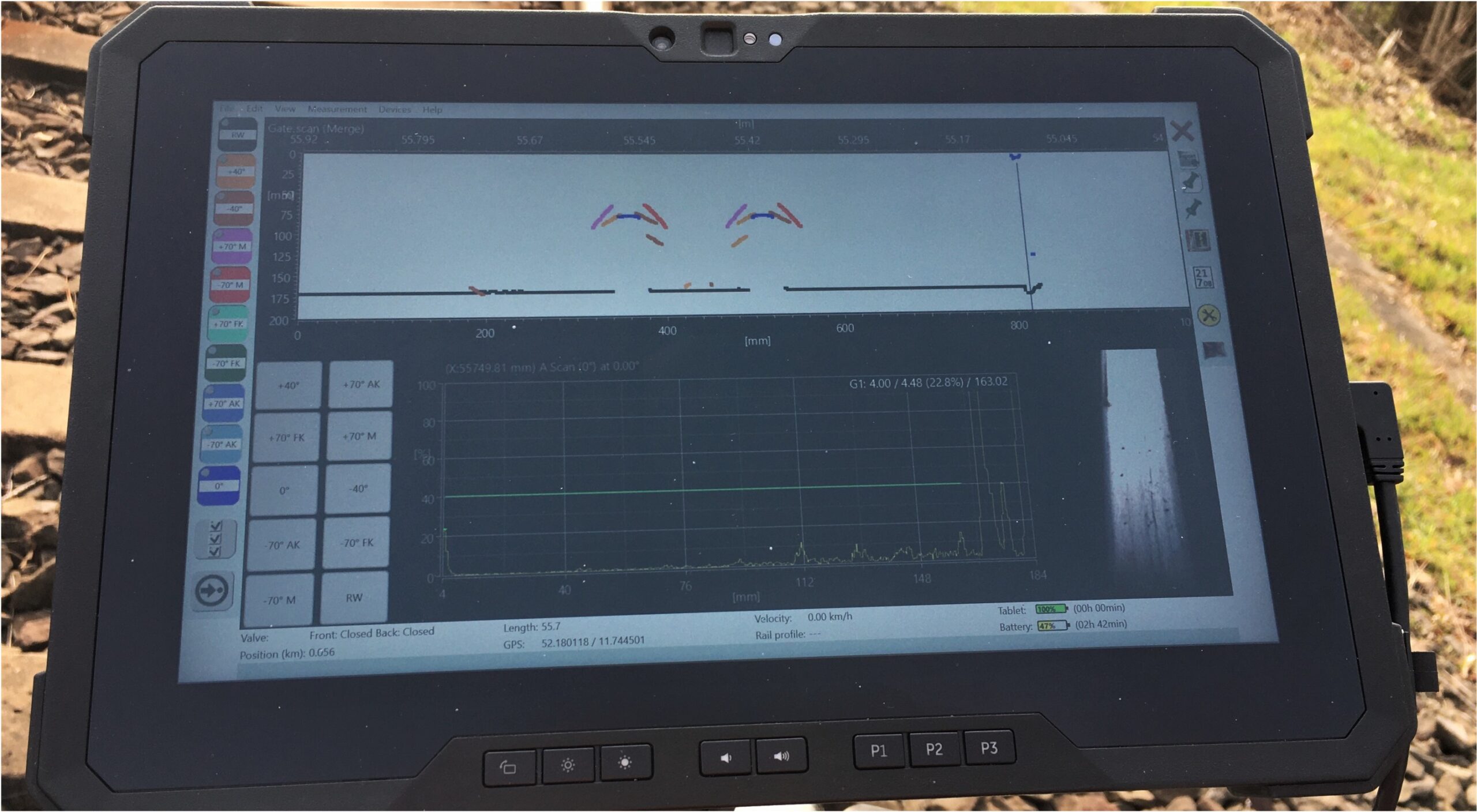

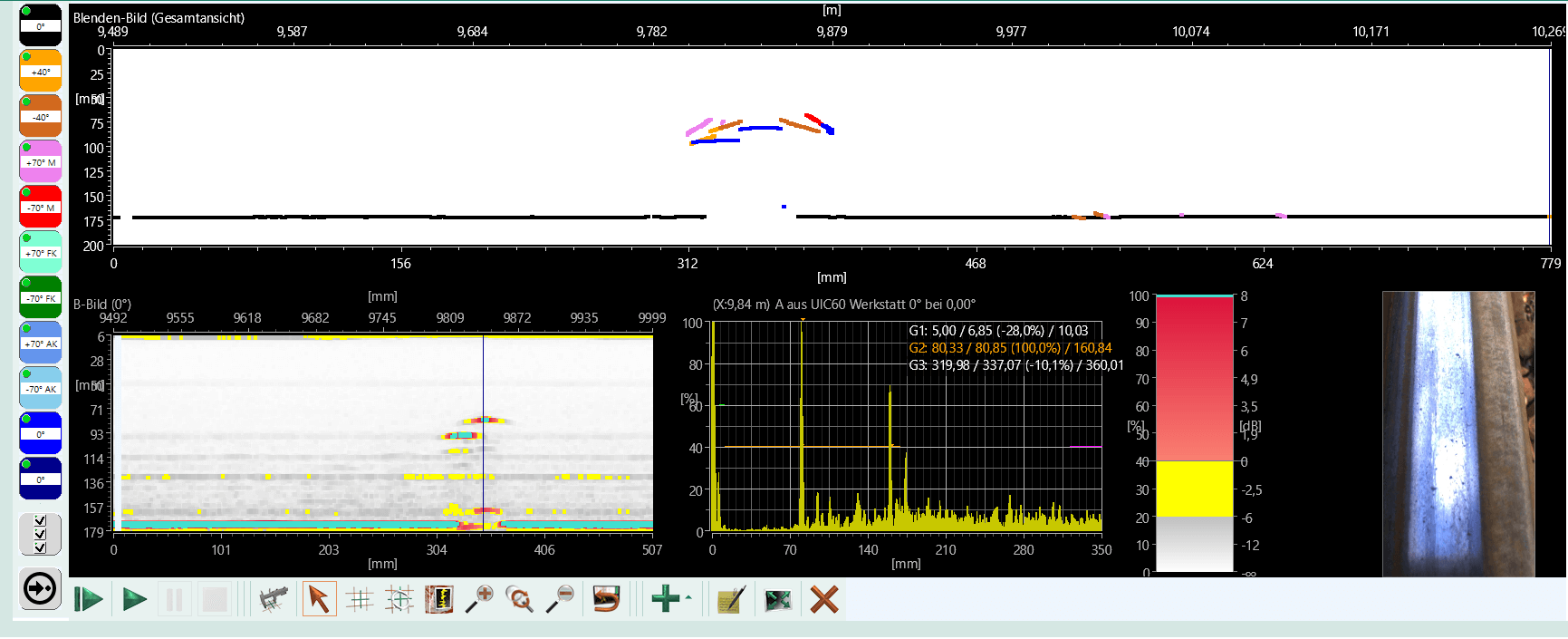

- Control, recording, display of inspection data and analysis carried out by same software designed by our cooperation partner Fraunhofer IKTS:

- Ultra-modern, modular testing electronics from the PCUS pro® family for recording data in accordance with DIN EN 16729-1

- Rugged removable tablet with intuitively operable touch-screen & software from the PCUS pro® family for displaying and analyzing the findings

- Ultrasonic inspection trolley with ten channels for nine probes mounted in the test wheel and one connectable standard probe

- New technological standards with the SoniQ Rail Explorer:

- More reliability with the analysis and interpretation of data

- Test results can be immediately integrated into a digitalized chain of processes

read more

read less

Optional components

Optional product features provide a considerably more revealing picture of the rail‘s interior:

Camera

Every photo of the rail surface is saved with the ultrasonic testing data under the same location reference

> Comprehensive documentation of the rail’s condition including its maintenance history

> Comprehensive documentation of the rail’s condition including its maintenance history

Artificial Intelligence

Automated detection (pre-classification) of the reflectors of serious rail defects through the use of learning algorithms with the results displayed to the inspector

> Assistance with the evaluation process

> Assistance with the evaluation process

Augmented Reality

Perspective-accurate display of the indicators detected as 3D volumetric VR image overlay of the rail

> Simplified interpretation & classification of the findings

> Simplified interpretation & classification of the findings

Visualization of the reflectors

Evaluation of the inspection data: versatile & revealing

Data handling

Data logging

- All the raw data or all the raw data above a specific threshold

- Sufficient memory to inspect approx. 30 km of rail (normal operational conditions

Data analysis

- Online and off-line

Data transfer

- Via LTE / WiFi, USB, SD card

Reports

- PDF export of tablet display

- Xml of damage reports

- Raw data exported in csv format

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

Sophisticated design & easy to use

Objectives when developing the design: light-weight, easy to use and extremely sturdy for use trackside

- The trolley‘s compact size:

In operating mode: 870 x 300 x 930 mm (L/W/H);

Transport dimensions 1,100 x 300 x 580 mm (L/W/H) > fits in the back of a car no problem - Carbon-fiber reinforced plastic for a weight of under 20 kg

- Slimline body design ensures weight is evenly distributed and makes the device easy to carry

- Suitable for left-handers as well as right-handers

- Optional shoulder strap also available

- If required, the SoniQ Rail Explorer can be upgraded to inspect the left and right rails simultaneously

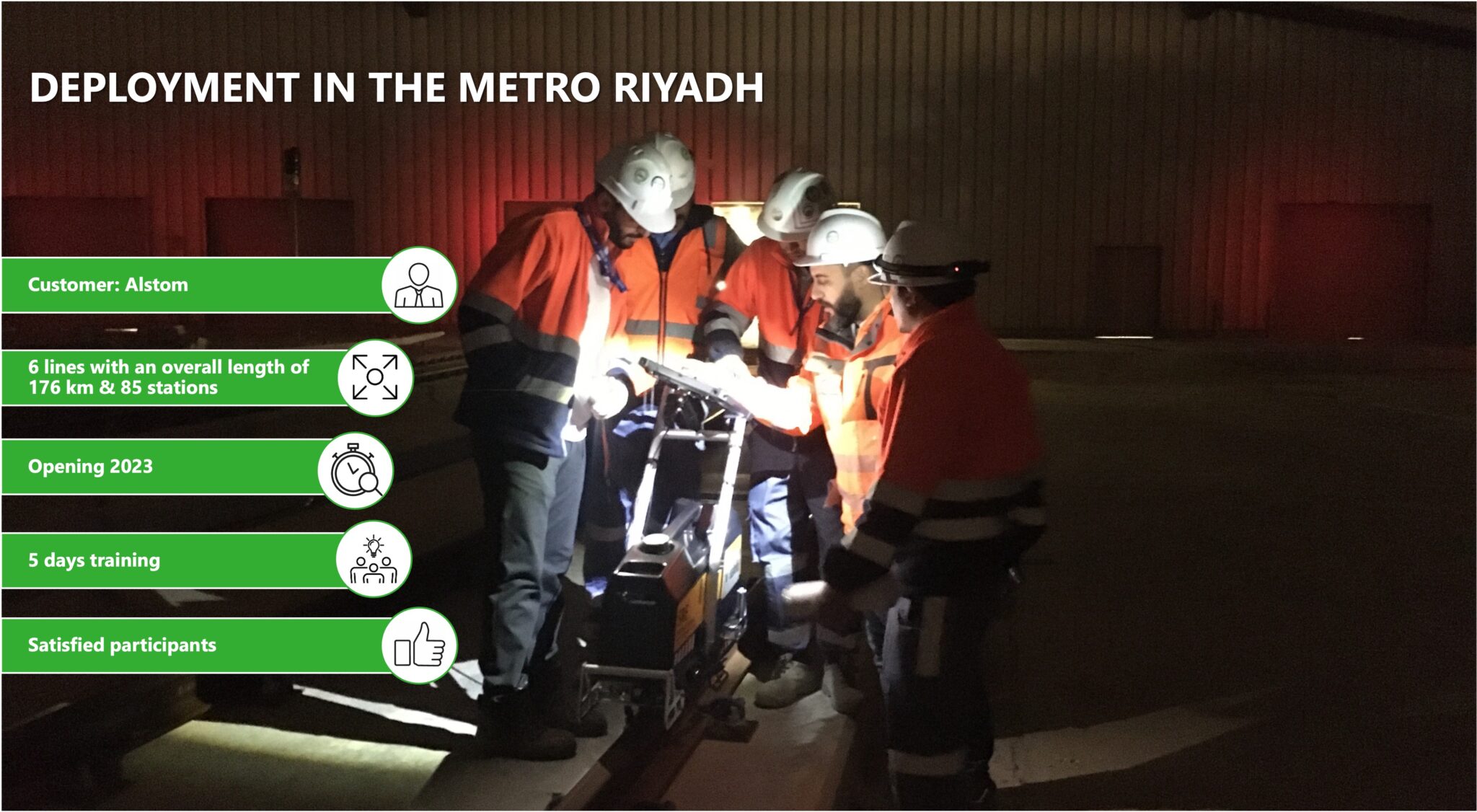

Selected references

Services

Device sold worldwide

- Ideal for rail network operators as well as railway infrastructure companies and service providers active in the railway industry

Vossloh Service

- Practical training in the used of the SoniQ Rail Explorer and its software is available at any of the three Vossloh locations (Leipzig, Berlin, Hamburg) or on the customer‘s premises (Germany)

- A field manager monitors inspections

- Manufacturer carries out annual check-up and calibration of tester as per DIN EN ISO 12668-1 and ISO 22232-1

- Maintenance and spare parts procurement

- System check-ups and software upgrades

- Analyses carried out of the data you record

- Dynamic customized SRE management (optional functionality can be purchased)

- Performance of testing services

Rail inspection as a service throughout Europe

- Established & reliable partner

- Many years of experience in service and maintenance using manually-guided ultrasonic testing devices