Specials InnoRail India 2022

Improved Fastening Systems for Modern Railway Lines in India

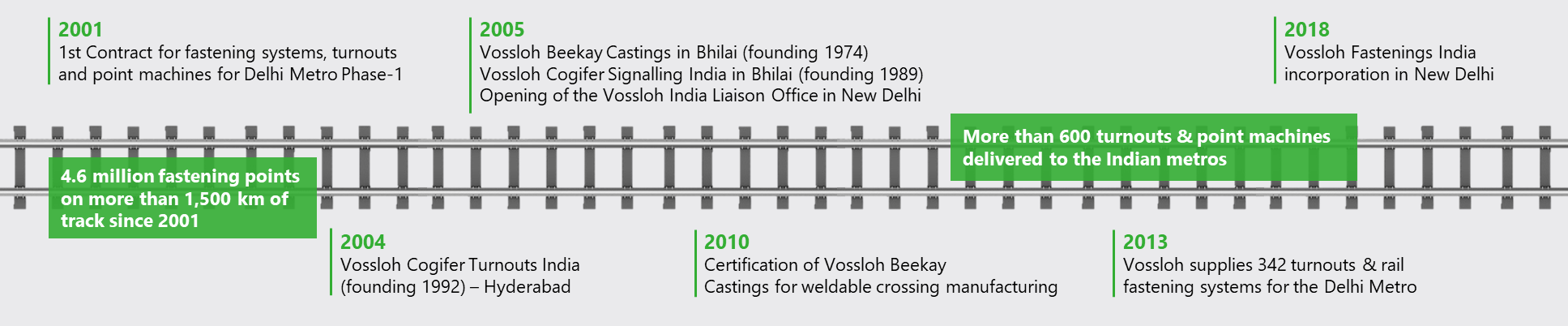

Dedicated to India for decades

- By leveraging the vast experience of its designers and technical team, Vossloh has adapted its high-technology products to suit local requirements while retaining the essentials, such as safety requirements.

- The ultimate aim is to provide Indian customers with competitive solutions – on-time & on-quality.

- Providing Indian Metro operators with more than 600 turnouts & point machines and 1.9 Million rail fastening systems, Vossloh has contributed to most of the metro projects in cities like Delhi, Bangalore, Hyderabad, Jaipur, Kolkata, Lucknow, Kochi and Mumbai.

- Via its three RDSO-approved manufacturing units, the Vossloh group has been supplying Indian Railway Zones over the last decades without interruption, positioning Vossloh as one of the key supplier of rail infrastructure in India.

Innovation & local presence

- Committed to the modernization and expansion of Indian passenger, freight and metro networks, Vossloh local team is working closely with operators to introduce modern and proven railway infrastructure.

- Innovations such as canted turnouts with swing nose crossings for high-speed lines or new IRS points machines are driven by the development of a local and sustainable manufacturing presence under the umbrella of the “Made in India” guideline.

Modernizations in Indian railways

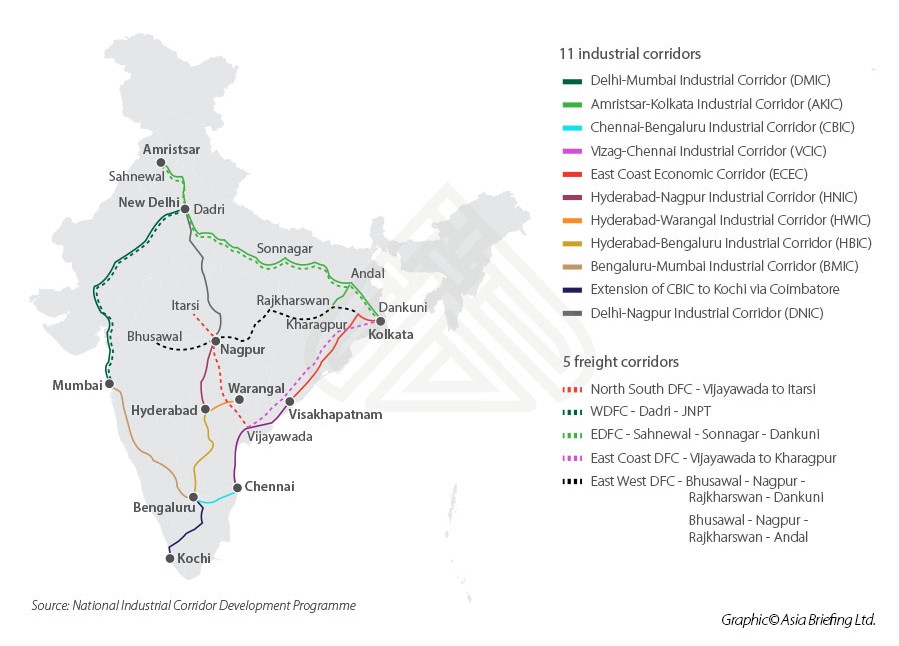

Growth accelerator:

- Exponential increase in passenger & freight traffic

- Shifting freight to rail

- Dedicated freight corridor

- Freight business development portal

- Diamond quadrilateral network of high-speed trains

Challenges:

- One of the largest railways networks – more than 120,000 track km

- One of the most established networks – since year 1853

- Long distances – Kashmir to Kanyakumari (2,800 km)

- Maintenance backlog – issue of track accessibility

- Increasing passenger numbers – 2nd highest in terms of passenger per year

- Alignment – geographical features such as mountains, deserts and plains

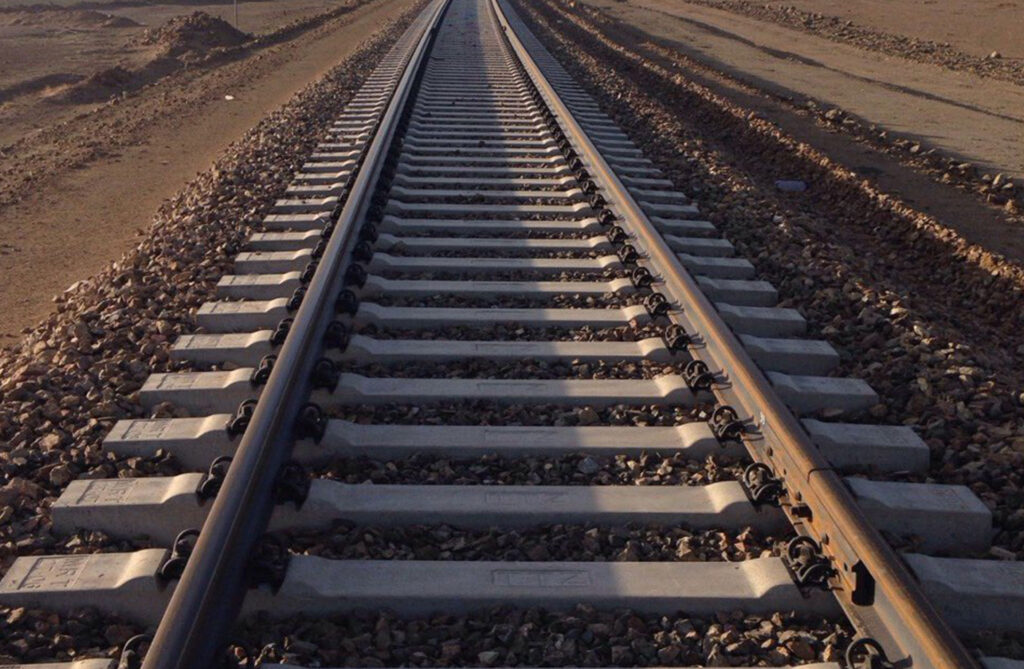

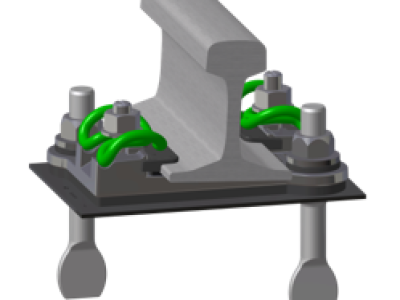

Our proposal: Fastening system W 30 - Putting Mixed traffic on the rail safely

Our weather-resistant special fastenings for heavy-haul & mixed traffic applications

- protect the entire track superstructure from material fatigue and

- ensure stability even under the high loads and in narrow curves.

- Thanks to easy installation and flexible subsequent component options, they

- minimize initial investments as well as current operating and maintenance costs.

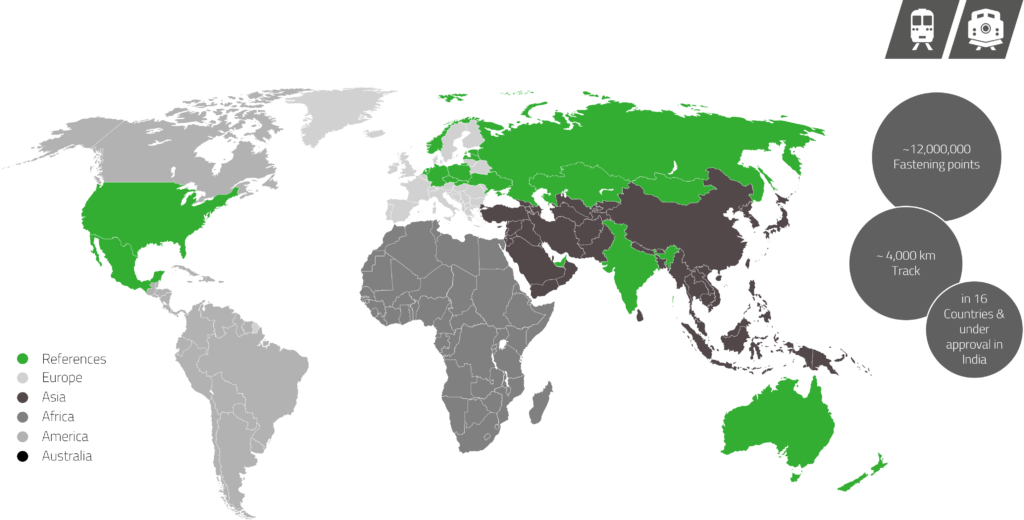

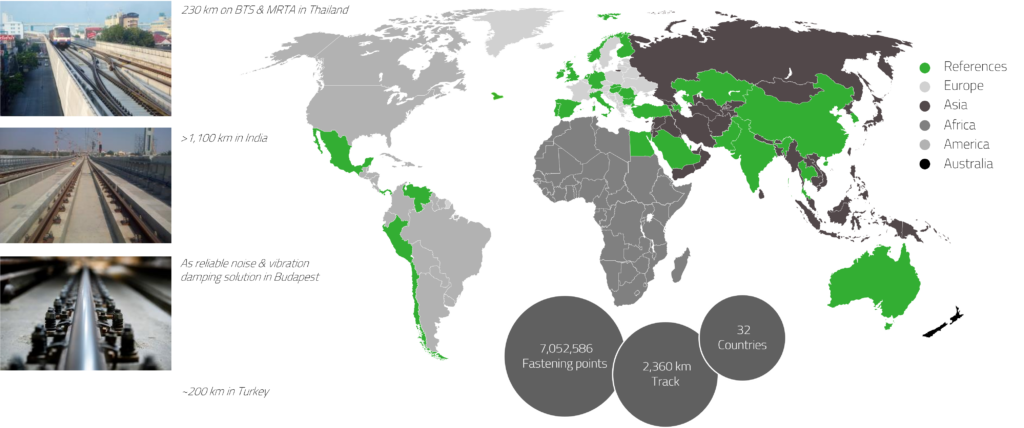

References worldwide: System Family W 30

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

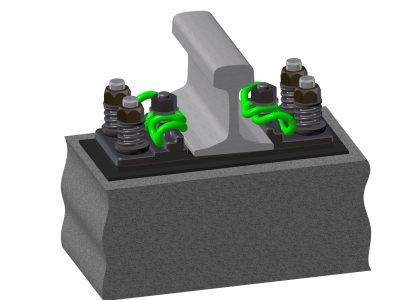

Highly elastic solution in urban transport: System 336

- Proven ribbed base plate solution for urban transport for over 40 years

- Particularly suitable for metros & popular rail fastening system for turnouts

- Forces generated by a rolling train are deflected into the ground in a smoothly & material-saving way

- Highly elastic elastomer intermediate plate made of cellentic offers excellent characteristics in terms of rail deflection, noise and vibration damping while the steel ribbed base plate forms the connection to the concrete subgrade and ensures track security and the stability of the rail as well as transfers dynamic forces in the substructure.

- The use of the two-bolt variant offers logistical and economical advantages.

References worldwide: Since 1972, the System 336 has been installed worldwide on more than 2.300 km

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren