Engineered Polymer Pad Ballast Shield

For a longer service life of Ballast & railway components

User benefits

- With EPP Ballast Shield, we offer customers environmentally friendly & economical protection of the ballast by increasing the contact surface between the sleeper & ballast. Under sleeper pads generally ensure optimized lateral track stability & vibration reduction.

- Overall, this leads to less wear on ballast & infrastructure components & extends tamping intervals, which also reduces operational disruption & life cycle costs.

Features of EPP Ballast Shield

- “Greener”: a new type of material mix made from recycled materials, which is of course produced using green energy.

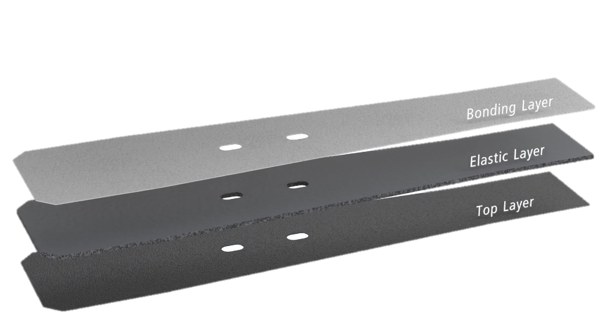

- Consists of three layers

- Available in two thicknesses: 7 and 10 mm

- Increased safety in track: improved lateral sleeper resistance by reducing the risk of track buckling at high temperature changes.

Our EPP Ballast shield consists of three layers:

- The surface layer is resistant but still allows the ballast stones to penetrate.

- The foamed middle layer allows the precise adjustment of elasticity. It helps to reduce the dynamic load on the rail infrastructure components. This is because many customers are currently switching to 100% soling on highly frequented routes – including turnouts – to protect the ballast and adjust the elasticity.

- The bonding layer ensures a good bond to the concrete during sleeper production & at the same time guarantees easy separation to enable complete recycling at the end of the service life.

×