PM-DiagBox makes regular point machines smarter

Vossloh’s technology detects a drop in performance, allowing us to optimize maintenance. In this way, we serve the customer’s desire to improve the operation of the line and thus provide a better service for passengers.

- Factory installed in the switch drive mechanism

- Improved operating capacities

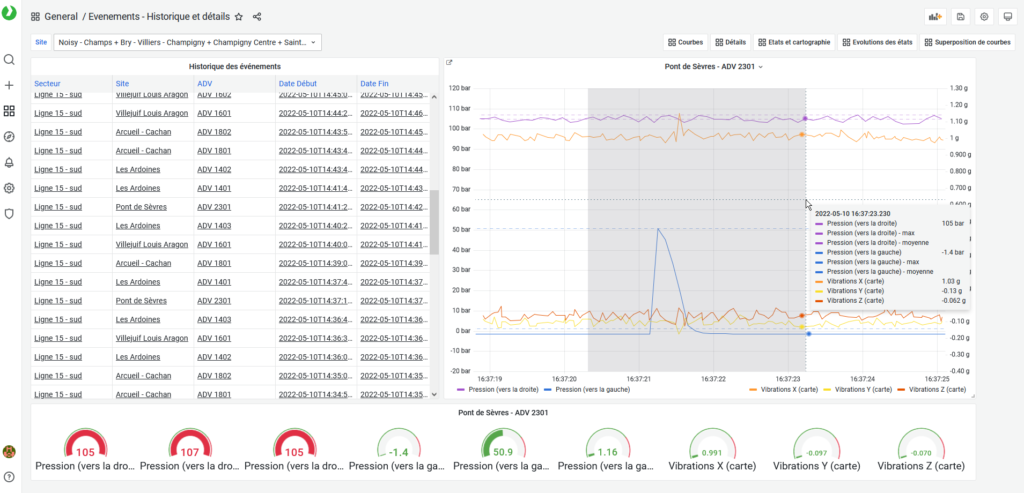

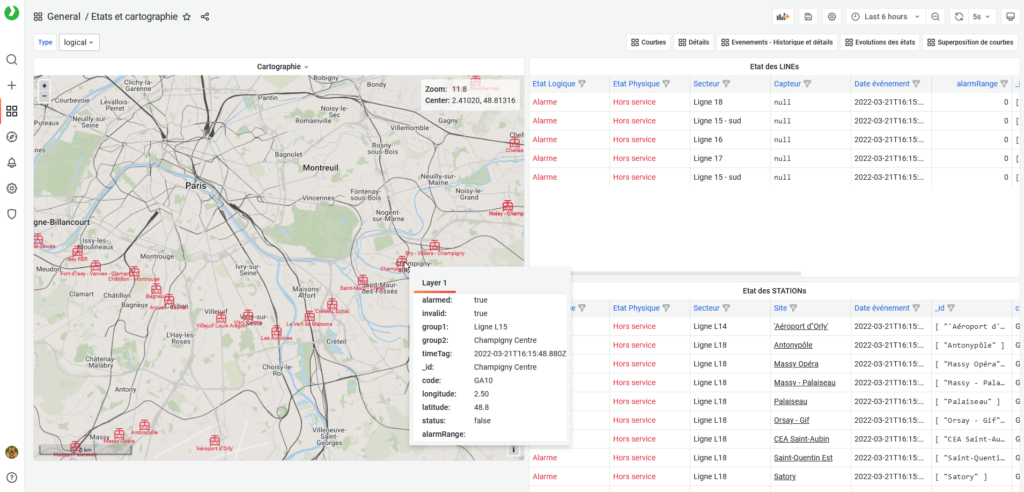

Monitoring all physical characteristics of a point machine

- The acceleration and vibration sensors measure the electrical current, vibrations and the hydraulic pressure to allow drawing inferences concerning the capability of the drive mechanism and slide chair operations.

- Connected to the modular V-MON architecture, the measured values get analyzed and are compared to the physical behavior. An algorithm developed by Vossloh experts enables the early detection of warning signs of a malfunction. The Vossloh connect platform supports the deep analysis process. The concentration of data can also run on a physical server or within the customer architecture.

- Asset managers can easily define meaningful maintenance intervals and – in case of deviating results of the real-time evaluations – trigger appropriate measures to counter possible undesirable developments at an early point in time.

×

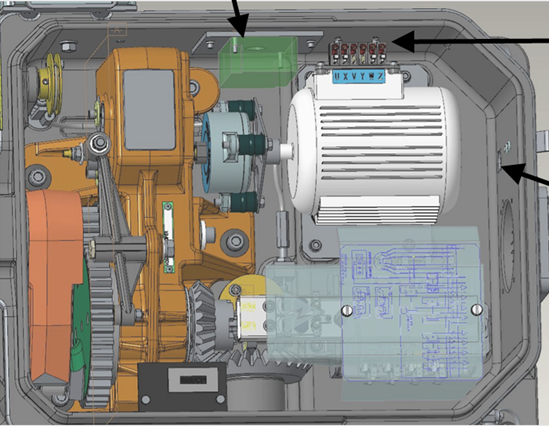

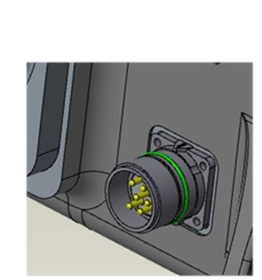

Plug-&-play: Get your additional product feature

Data acquisition device

X

Connection to motor power supply

X

Connector

X

Sensors:

- 2 electric power sensors

- 1 Accelerometer 0-200 g

- 1 Temperature probe

- 2 inputs for option:

- Humidity sensor

- Other sensors on request

Characteristics:

- Approximate dimensions: 100 x 150 x 60 mm

- Accelerometer & temperature probe are integrated into the housing

- Waterproof case

Control monitoring:

- Power consumption Current

- Pressure

- Vibrations & chocks 3 axes

- Temperatures

- Humidity

The right timing in the project

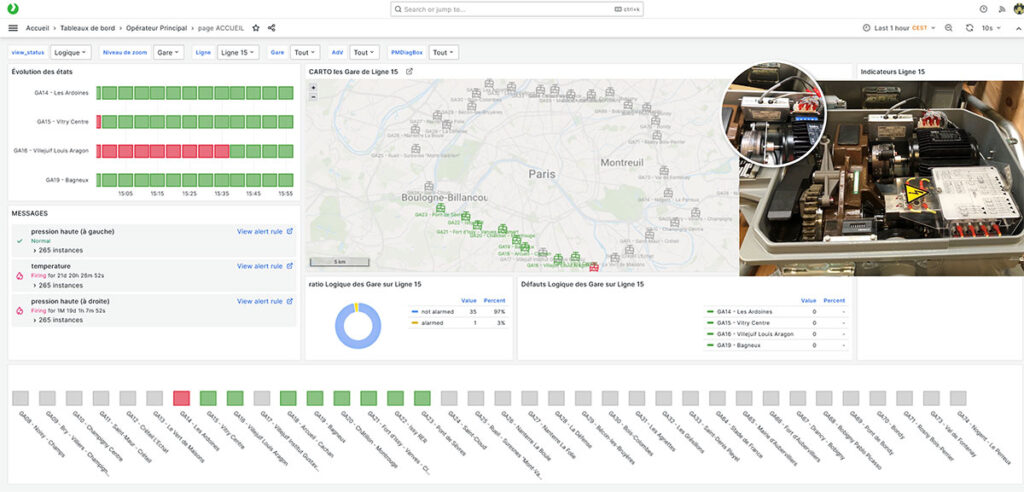

Customers benefit from the PM-DiagBox & V-MON portfolio irrespective of their project status:

- Be it a specific requirement for an already identified problem,

- a step-wise integration, or

- a stand-alone diagnosis as first step.

For example:

- All of the switch drive mechanisms to be installed as part of the Le Grand Paris project come with the factory-installed PM-DiagBox for future monitoring tasks.

- Another commercial breakthrough for the convincing offer in terms of quality of measurements and transmitted data was the contract signed with Siemens Mobility in May 2021 for the supply of 227 point machines MCEM91 with the new PM-DiagBox for the turnouts on Singapore Metro’s fully automated Jurong Region Line (JRL).