Railway superstructure inspection

Inspection of the assigned specifications and tolerances, allocation to the respective acceptable minimum technical requirements under the premise that the correct turnout inspection cards with the specified and operational tolerances as well as the geometry specifications are provided by the client. For both of the new EMA scanning devices, our technicians developed useful additions, e.g. non-contact rail profile scanners, new on-board electronics and compatible operating software.

Our digital track measurement technology comprises:

High-precision track gauge for multiple gauges with continuous rail scanning and laser-assisted transverse profile measurement for quantifying rail wear

RSV LaserScan (EMA uni)

Measurement of track geometry

First and to date only continuously measuring turnout inspection system with DB approval (automatic-continuous digital data acquisition at intervals of 5 mm)

Identification of the rail type by scanning the contours of the rail head. By comparing the actual condition with the new profile, deviations are quantified and, if necessary, the need for reprofiling is determined.

RSV LaserScan (EMA uni II)

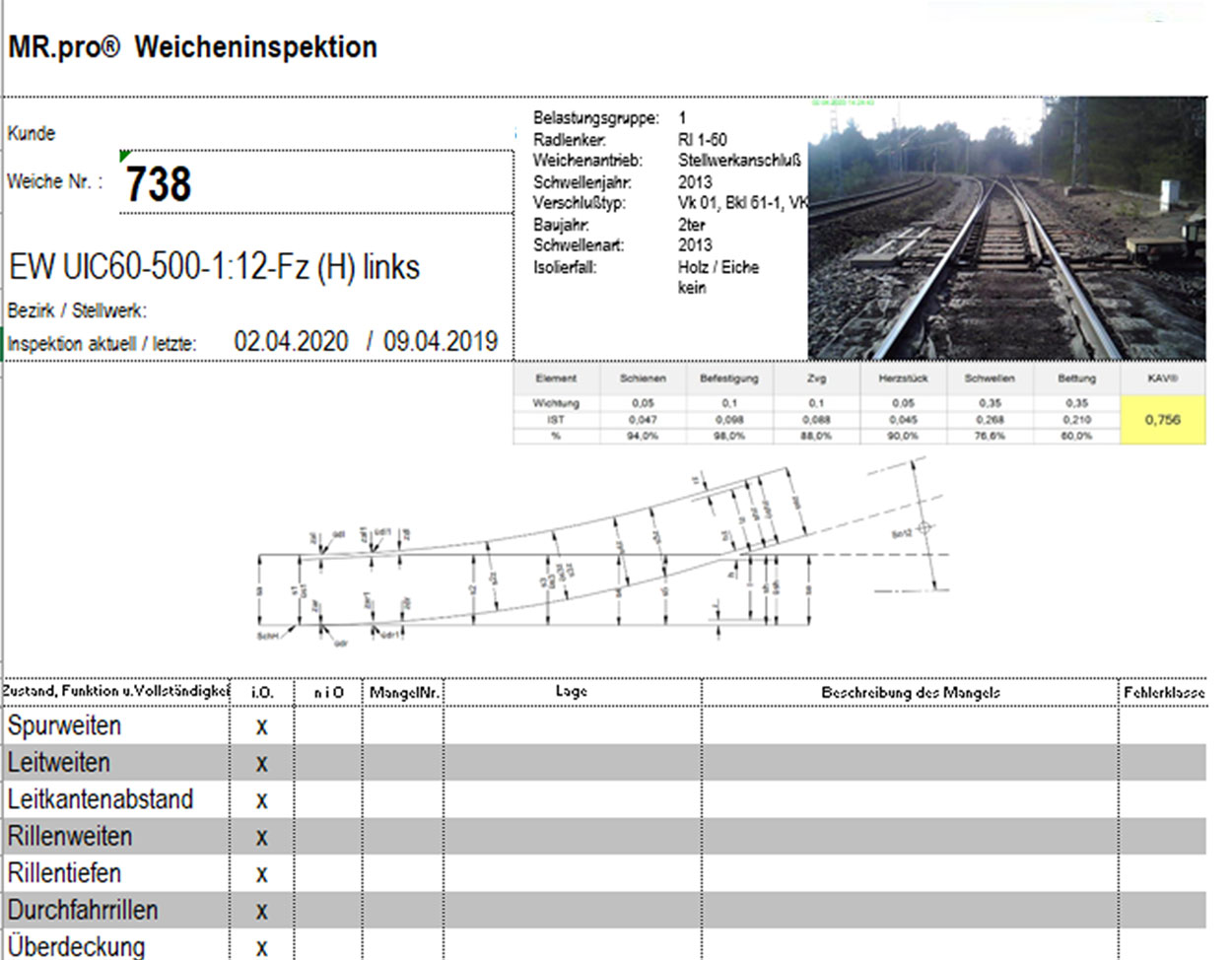

- Visual inspection according to checklist (MR.pro®), because measurements are taken in unloaded condition and the measured values can be influenced significantly in operation and/or under load.

- (Initial) inspection for the complete master data creation as well as for the evaluation of condition and wear:

- Visual survey of type of construction/superstructure, configuration/specification, age, manufacturer, locking technology, etc.

- Quantitative measurement of geometry, lengths, transverse dimensions, coordinates, rail profiles, etc.

- Condition recording and assessment of maintenance requirements (scope of work, priority, sequence)

- Determination of causes of nonconformity with operational tolerances and allocation of the detected defects to the measured section

- Condition recording with MR.pro® is ergonomically designed for a minimum expenditure of time

- Dialogue guidance ensures that nothing is overseen, while the plausibility check prevents possible operator errors

- Photo for a quick identification of asset & surroundings.

- Extensive documentation for a quick & user-friendly evaluation

Maintenance management

- Interpretation, condensation and verification by our experts transform the gathered data into useful information

- Clear and easy-to-understand documentation provides a solid basis for decision-making:

- Reliable, reproducible results

- Meaningful, clear and comprehensible for users, decision-makers & regulators

- Transparency and easy interpretation without specialist knowledge or additional aids

- Detailed individual results & condensed overall results

- Uniform traceability of the development of the track condition

Assessment & classification methods

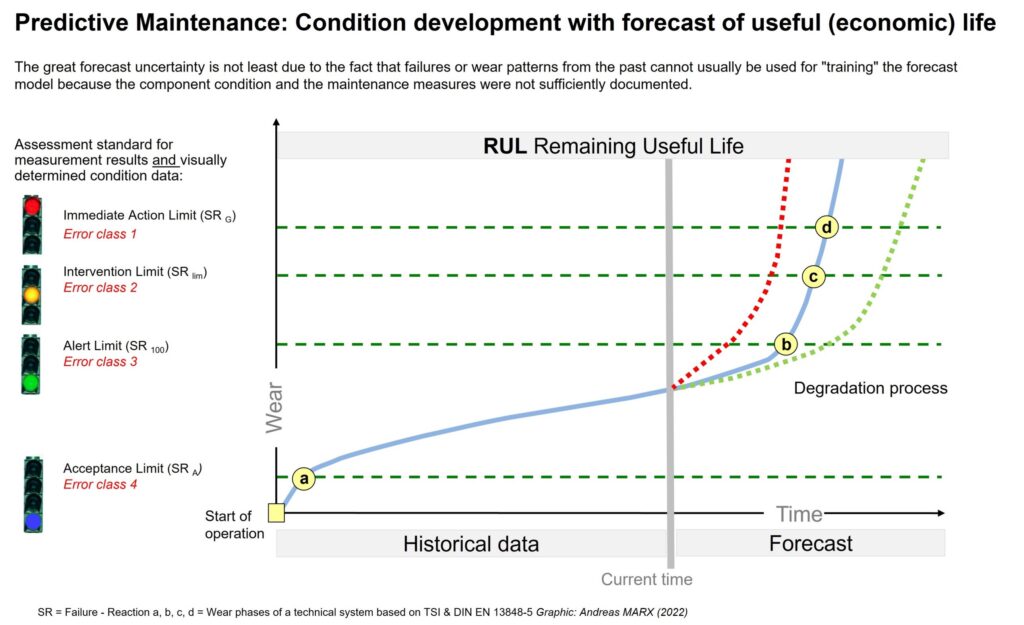

Classification of defects in terms of their safety relevance (defect classification) and economic efficiency (remaining useful life)

- Defect classification: classification of all defects of turnouts or tracks according to their importance & urgency into 4 defect classes.

- Asset classification: classification of the tracks and turnouts according to their importance into three location classes (jointly with the client); determination of construction site classes based on lost time, disruption of the regular traffic flow as well as load and speed.

- The aim is to derive and prioritize sensible and correct repair work to eliminate the identified defects.

Development of wear limits

Modular structure permits individual solutions for all tasks.

Customers themselves determine the right mix of services & own work: from consulting & planning via initial assistance for the internal development of maintenance work and services to the all-round carefree package.

Advantages:

- Qualification of decisions and planning

- Increased the efficiency of work planning

- Reduction of execution errors/deficiencies

- Transparency about the condition development

- Objective check of visual inspections and condition assessments

- Fulfilment of quality management requirements

- Provision of data for decentralized and centralized access as well as for long-term analyses

- Protection against liability risks

- Reproducibility of decisions

Asset management & turnout service

Complete service from a single source

Turnouts and crossings take on a special position within track systems – they combine components from different specialist areas. If all services come from a single source, expensive interfaces and unnecessary waiting times can be avoided.

Each turnout service team consists of two specialists who complement each other and are able to carry out all work on turnouts.

In order to maximize the useful life of turnouts and crossings, our asset managers take care of compliance with all requirements and specifications for the track infrastructure.

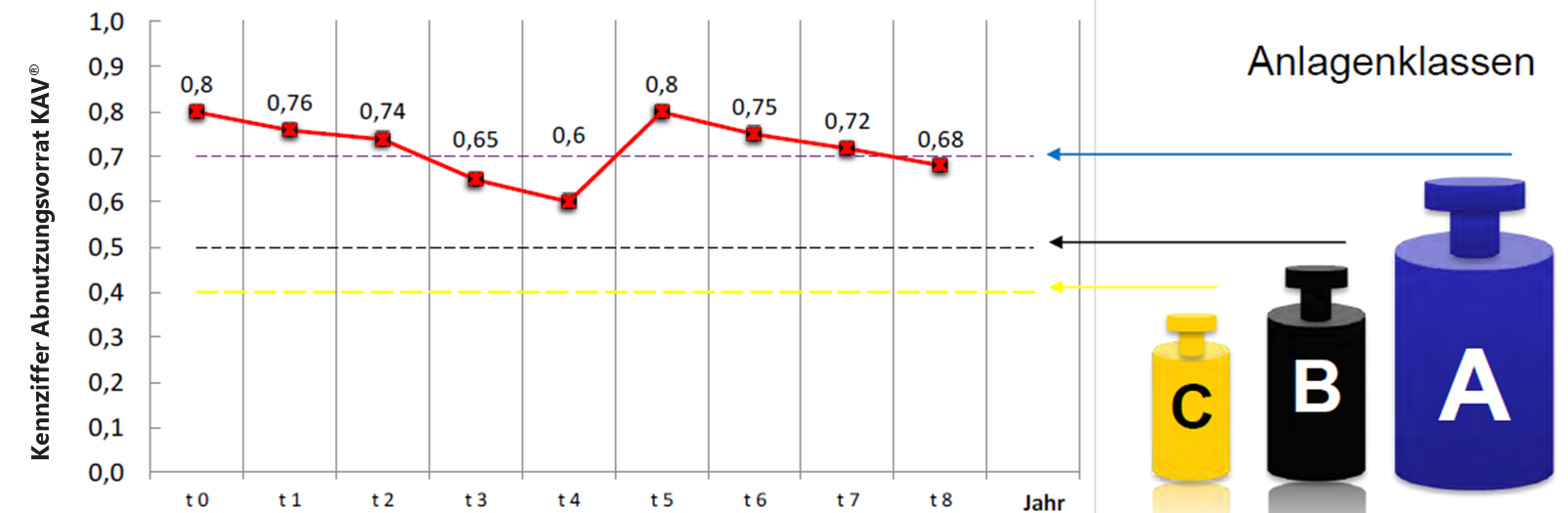

Using the wear reserve index (KAV®) as a parameter, the renewal planning can be scheduled and realized as required in the short, medium and long term.

Our maintenance modules for turnouts and special constructions

Locking & drive engineering

Straightening engineering

Welding

engineering

Grinding

engineering

Track & superstructure engineering

- Assembly, adjustment & disassembly of drives & locking devices

- Maintenance, cleaning & inspection

- Installation & removal of switch locking devices

- Implementation of special solutions

read more

read less

- Straightening of switch blades

- Correction of longitudinal & transverse height defects on rails

- Correction of derailment damage

read more

read less

- Digital recording of transverse dimensions (gauge, guide & groove widths), e.g. with PTP II & CDM

- Measurement of leading edge distances

- Determination of transverse and longitudinal heights

- Determination of turnout & crossing geometries

- Measurement of locking device & drive dimensions

- Determination of changeover forces

- Profile measurement, ultrasound and eddy current testing

read more

read less

- Rail joint welding

- Build-up welding

- Welding repair of damaged areas

- Welding of guard rails & switch blades

read more

read less

- Reprofiling of switch blade & rail transverse profiles

- Removal of burrs & rolling laps

- Repair of damaged areas & crossings by grinding

- Corrective grinding of corrugations

read more

read less

- Correction of track, guide & groove widths

- Restoration of leading edge distances

- Treatment of track fastenings and other hardware

- Replacement of major turnout components

- Tamping services

- Cleaning services

read more

read less

Preserving value through expert maintenance

Our asset managers take care of compliance with all requirements & industry-specific specifications for the track infrastructure:

- Secondary railways (Obri NE) and industrial railways (connecting railways (BOA))

- Tramways (BOStrab)

- Special constructions:

- Rail-bound conveyors (e.g. in high-bay warehouses)

- Crane railways (K+S)

- Monorails (Wuppertal suspension railway)

- Special structures (turntables, traversers, transformer crossings, etc.)

- Crossings in mixed EBO/BOStrab traffic

- Mainline railways (DB according to EBO)

Your benefit

- Reduction of the costs of repairs

- Increased availability through the bundling of interventions

- Accelerated & simplified project handling through elimination of interfaces

- Regional availability

- No need for own spare parts inventory

- On-call service

Gantry train installation in the K+S workshop: New crane rails in a salt dome 940 m below ground

Wuppertal suspension railway:Repair of railway expansion joints

Turnout conversion DB station Lindau–Reutin: Targeted correction of a diamond crossing with double outside slip roads

BahnWege® seminars

Further training with know-how and passion

- The training organization BahnWege® seminars has been recognized by the German Federal Railway Authority (EBA) as a training organization according in accordance with TfV. Our training program is directed at both (lateral) entrants and experienced employees:

- Practically oriented communication of basic knowledge of rail technology

- Further qualification through in-depth specialist knowledge

- Targeted functional training with examination

- Digitally supported learning formats

- Our speakers are experts in their respective fields who pass on their extensive knowledge to the participants.

- For in-house seminars, we put together a tailor-made program for your training needs.

read more

read less

Referenzen

In-person/hybrid seminars

“For me, the compact seminar on superstructure engineering designed as a combined online and in-person training was a well-rounded event. Both in the online-seminars and in the practical part, we were provided with a comprehensive general and subject-specific knowledge of the basics of railway superstructure.

Particularly informative was the discussion of superstructure defects and the maintenance and repair of the superstructure based on practical examples.”

Mike Chlebowski, LEAG, on the compact seminar on railway superstructure engineering 2021

“In addition to the excellent organization, the material taught was of a very high standard. It was understandable and no questions were left unanswered. I felt very well looked after and have and will recommend your seminars to others.”

Ivan Glisovic, GEBR. LUTZ Bauunternehmung GmbH + Co KG on the seminar on railway superstructure engineering KOMPAKT 2024

read more

read less

Functional training

“These were two exciting, interesting and informative weeks on site. We were taught everything we should and wanted to know. From the clamp lock to the latest latch lock, we were able to try out everything and bombard the lecturers with our questions. Also our creature comforts were perfectly catered for. All in all, one of the best seminars I have ever attended!”

Nico Kunze, participant of the functional training course as Vignole turnout fitter, 2021

read more

read less

CFL corporate training

The training course for turnout fitters LST for the Luxembourg state railways CFL has been available since 2019 as follows:

- Module I: Basics of turnout engineering

- Module II: Installation & maintenance of locking devices

- Module III: Installation & maintenance of the drive engineering for Vignole turnouts > Documentation and measurement of forces

- Module PM: Review course Modules I, II and III and theoretical and practical examination

“I got to know very nice & competent people who despite, or perhaps just because, of our own experience imparted further knowledge and showed different procedures for our work so that all participants had a great deal to take away.

I am already looking forward to the next training. Many thanks to the entire team for this successful first course in the training as locking device mechanic LST.“

Luc Greter, trainer LST, QM, safety at CFL

read more

read less

Forums

“I joined because I simple wanted to gain a broader view and discover new perspectives for the city. The recent lecture on the new safety for cyclists in connection with rails was particularly interesting. With an integrated rubber profile, we can create more cycling safety also in a grown city.”

Wiebke Stolz, Bremer Straßenbahn AG, on the Light Rail Forum 2021

“I enjoy meeting people who deal with the same issues as I do. You have a good exchange, good discussions and also get a great benefit from it.”

Sabine Sürth, Kölner Verkehrs-Betriebe AG on the Light Rail Forum 2024

read more

read less

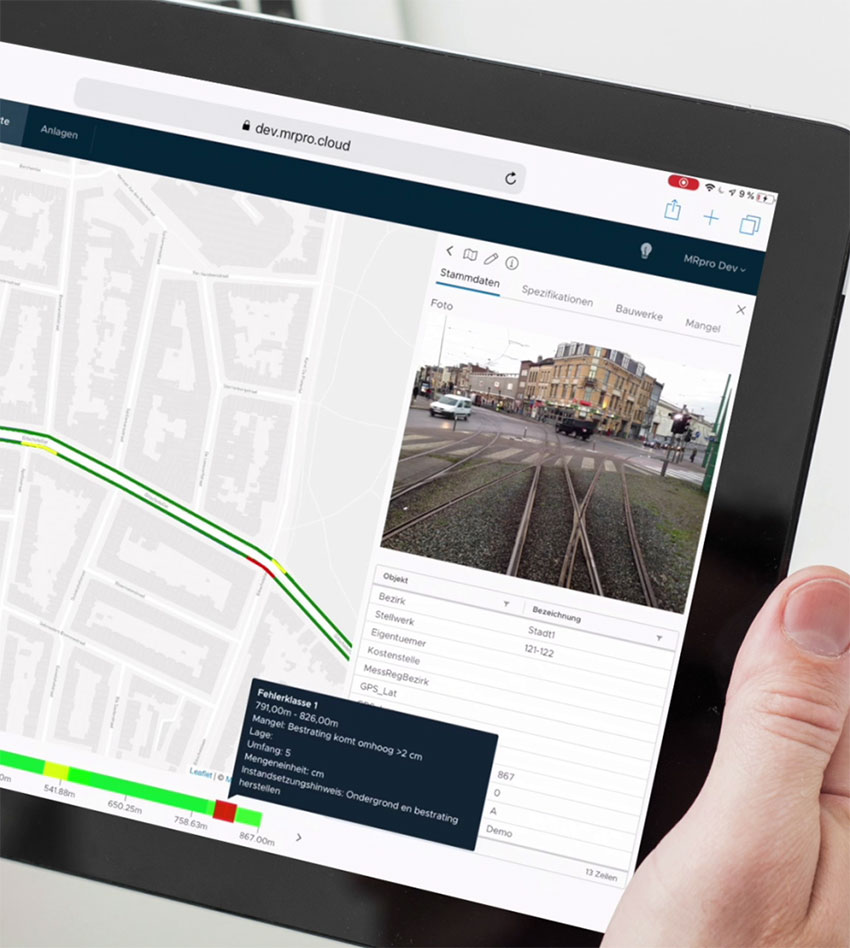

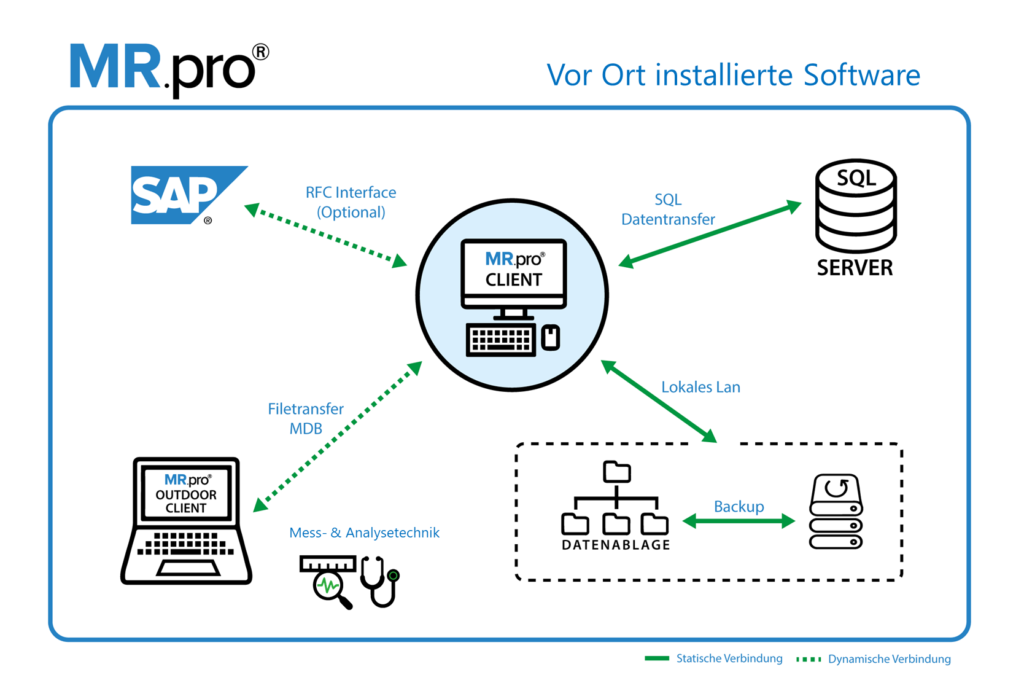

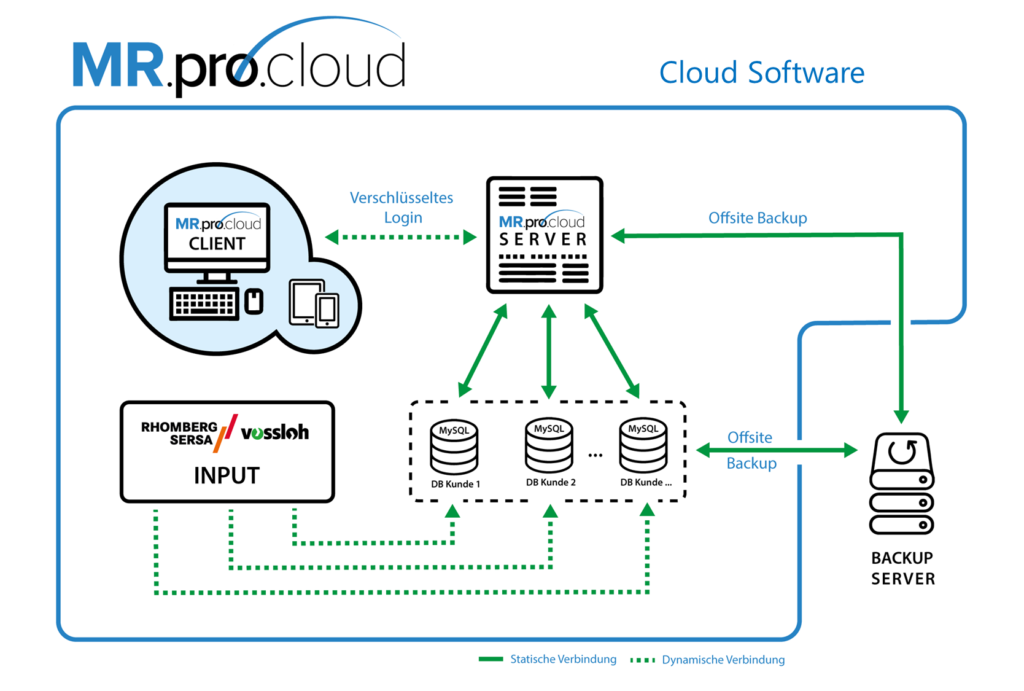

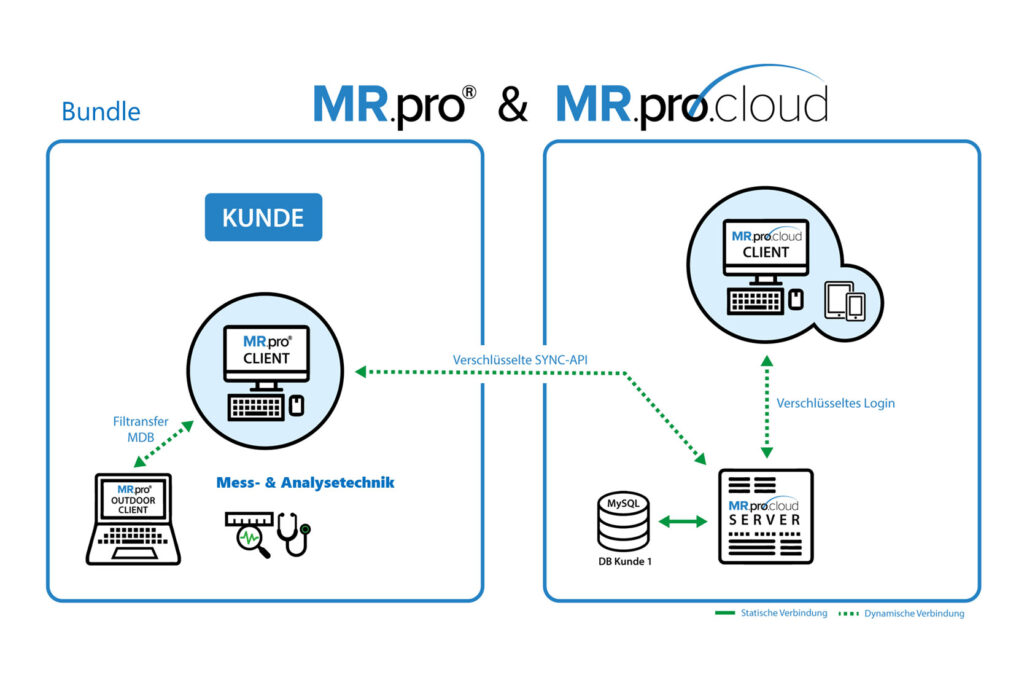

MR.pro®

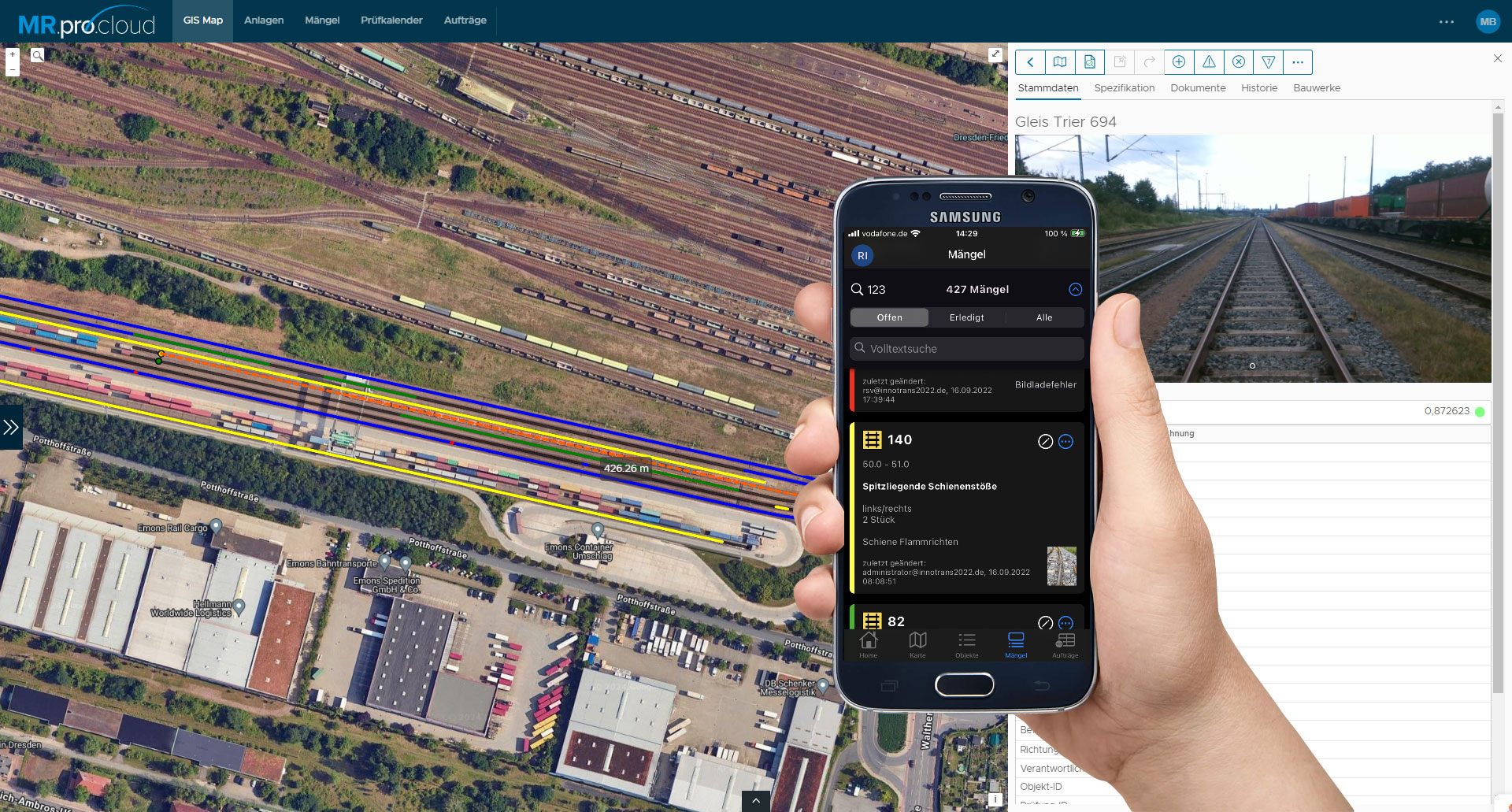

- MR.pro® is an asset management system designed for the total system of railway infrastructure that meets the specific requirements of each type and category of asset.

- This enables the software to provide asset managers with the necessary overview and show interrelationships.

- Thanks to the integrated workflow, the data maintenance effort is kept to a minimum, as the data, once recorded, are used throughout the entire maintenance process, so duplication of recording is avoided.

- Managing all types of objects in a structured manner in a single data model with a uniform framework avoids system and media discontinuities from the outset. Such a holistic data model facilitates understanding and communication and contributes significantly to an efficient division of labour.

Central system for all objects of the railway infrastructure – instead of fragmented data management

A special software for the “big picture” of railway infrastructure

- In addition to the track infrastructure, MR.pro® also manages traction power supply, overhead lines, signalling and communications engineering, stops, buildings and load-bearing structures, real estate, workshops, stations as digital twins in a data model with a uniform framework.

- Developed by railway technology specialists who are familiar with the needs of the users, the integrated expert system makes MR.pro® a kind of “sponge” for the experience-based knowledge of the specialists in the transport companies. It also has interfaces to ERP systems such as SAP.

- MR.pro® maps the entire process chain of infrastructure maintenance and provides all the information in a convenient and comprehensible way.

- An integrated, digital construction site management system that permits an easy and stress-free planning, control and invoicing of construction and maintenance processes: work preparation, construction schedule, construction diary, completion notification and invoicing of repair orders. This way, the overview in the office as well as on the construction site is guaranteed at all times.

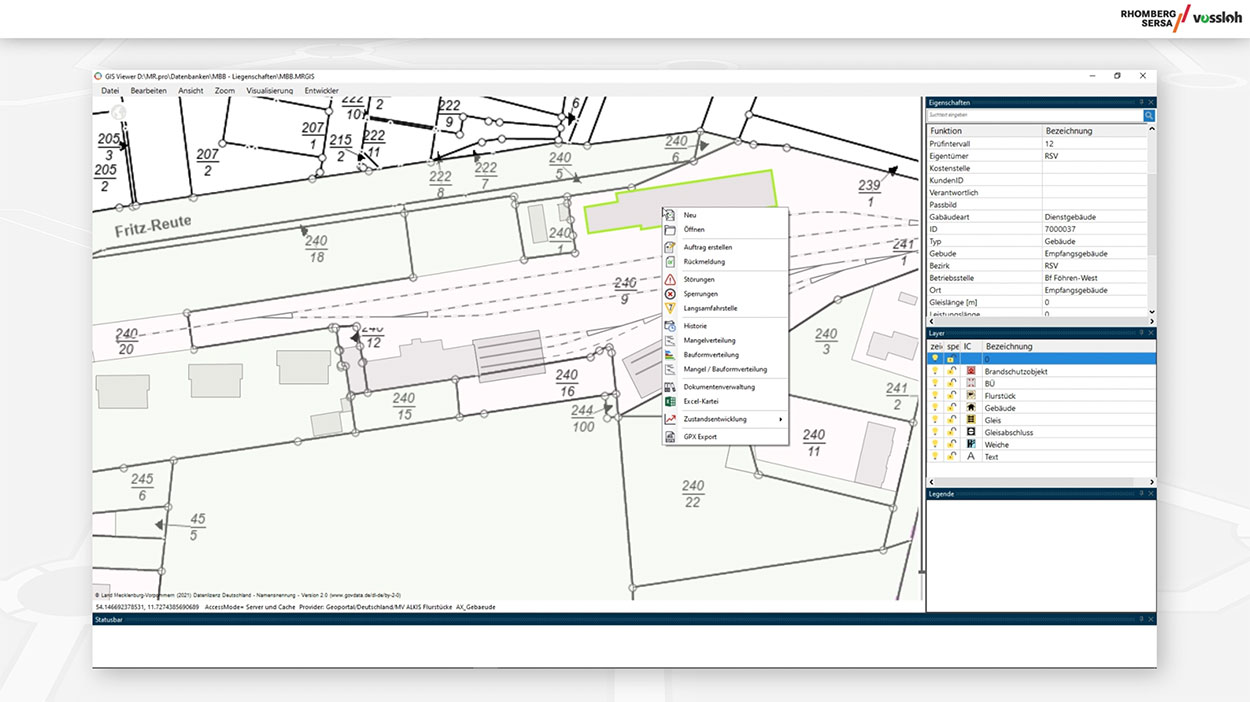

Geographical functions

For better orientation, all located inventory and condition data can be displayed to scale in maps or satellite photos; wherever it makes sense, also with colour coding in corresponding traffic light colours.

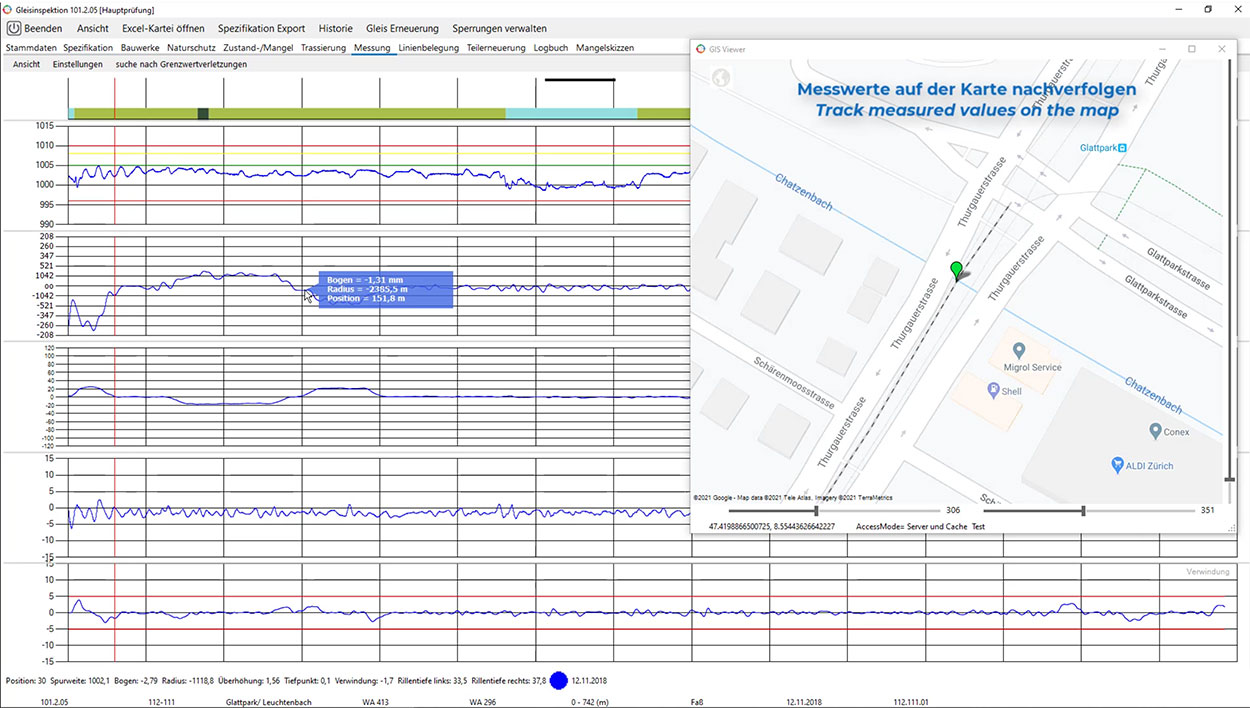

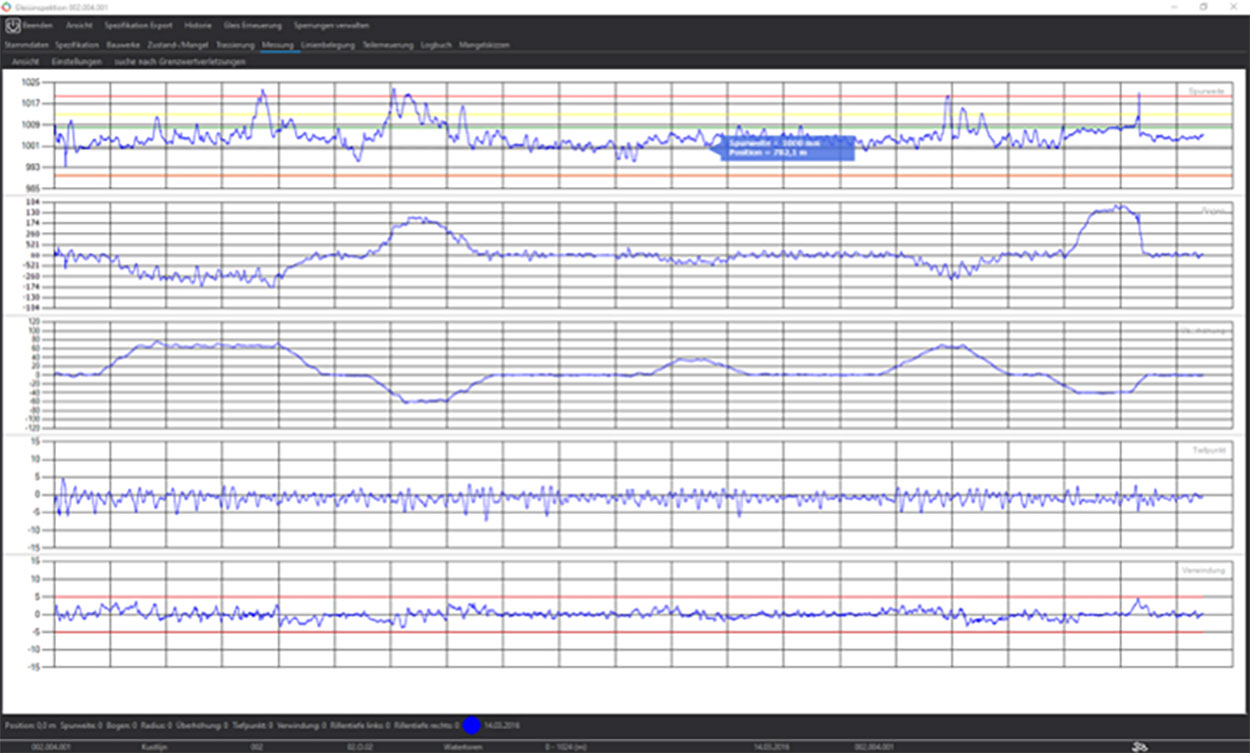

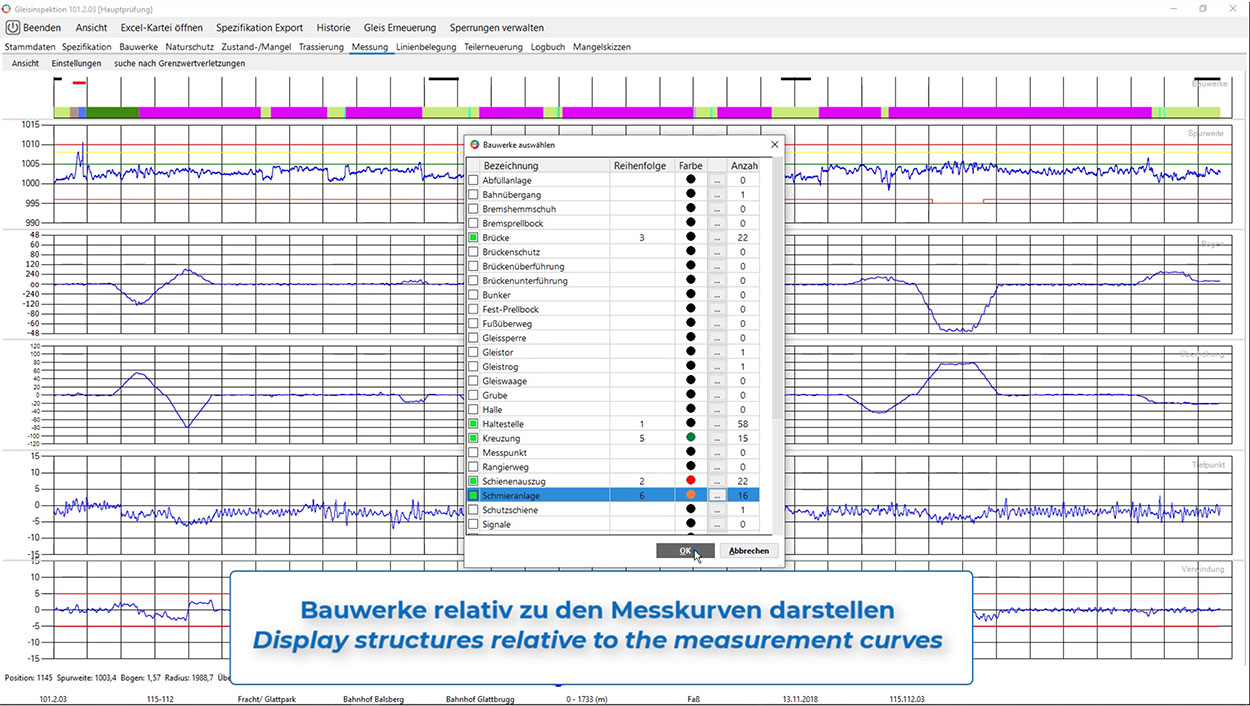

Measurement results

MR.pro® is designed to import and analyse raw data generated by common measuring equipment and to document this information in a uniform, manufacturer-independent format. Data collected with different measuring devices, and even mass data, can be displayed in overlays for multi-year comparisons – perfect for tracking the development of the condition.

- Clear arrangement

- Free selection of measurement parameters

- Structures (e.g. level crossings, track fixtures, switchgear, signals, etc.) can be displayed in a freely configurable manner in order to be able to detect correlations.

Buildings & properties

Numerous buildings, from filling stations to centralized traffic control offices, can be displayed in the route tapes and measurement records so their influence on the measurement results can be checked for plausibility and taken into account. Property management for land and buildings is also part of the functional scope of MR.pro.

References

Germany’s largest chemical complex relies on MR.pro®: Digital asset management system based on digital twins

Turnout inspection at the Luxembourg state railway CFL: Presentation of the superstructure in the GIS-Map of MR.pro® for convenient management

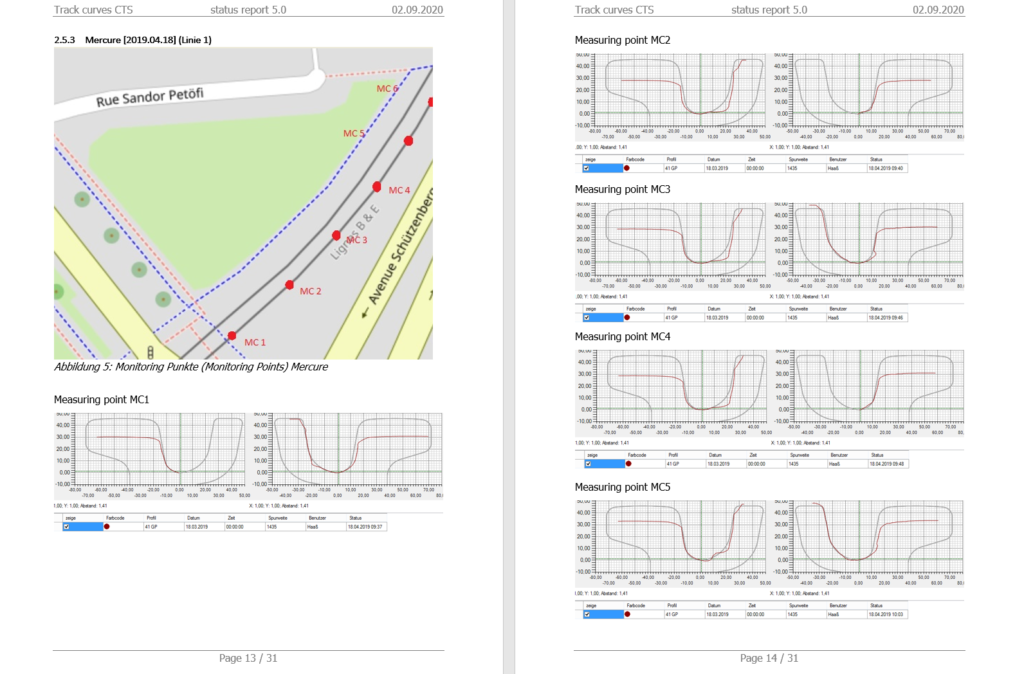

Highly efficient track maintenance in Strasbourg: 20 years of inspection of a growing track network

Wheel/rail system service

- In order to ensure a safe track guidance and the greatest possible running smoothness even in the permissible state of wear of the components, section 35 (1) of the German light railway regulations BOStrab requires a coordination of the vehicle and the track dimensions that are essential for the ride characteristics.

- The “right” combination of the two system partners, wheel & rail, enables a permanently safe and low-wear railway operation.

- A detailed track guiding analysis of the wheel/rail profile pairing usually identifies optimization potential for the interaction of wheel & rail.

Wheel/rail system service

- Design rating

- Gauge investigation

- Optimal interaction

- Knowledge management

The products and services listed belong to the Rhomberg Sersa Vossloh joint venture.