logistics

welding

turnout

installation

turnout

maintenance

monitoring

rail & turnout

maintanance

replacement

GS 1

crossing

Center

Rail Center

Long rail welding plant

User benefits

- Production of long rails, usually 180 m long, and pre-assembly for delivery to the customer/construction site.

- Precise prefabrication and welding of the rails reduces waste and

produces a precise and ready-to-install product.

Focus on track availability

- Enlarged capacities for just-in-time availability of all relevant rail profile, plus insulating & profile transition joints

- Removing the rolling skin reduces wear & ensures longer track availability

References

- Well over 100,000,000 m of rail supplied to date from 4 stationary

rail-welding plants in Europe - Contracts in Germany, Finland, Denmark, Sweden, the Netherlands, Switzerland, UK plus South Africa

Featured projects

- Riedbahn & HSL KRM, Germany

Production center for turnout solutions

Core activities

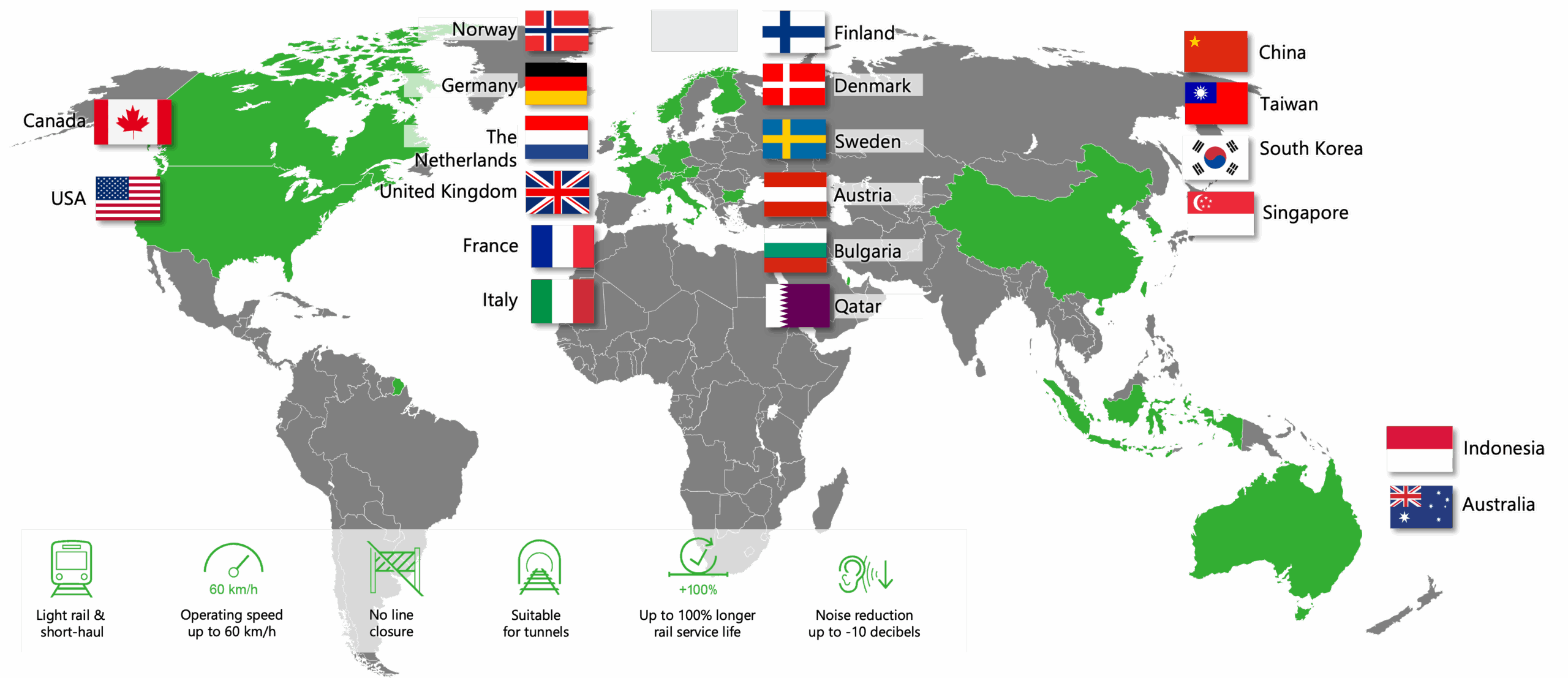

Industrial presence

- 19 companies and 22 industrial sites in 17 countries

- Being close to the customers with our local footprint contributes to solve issues and to support the customer within short delay

- Strong research & development capabilities, combined with a world-class industrial and logistics structure

Focus on track availability

- Contingency stock & on-call operations

- Market adequate capacity optimization at VSS sites

- Investments in either new factories, equipment or production lines in conjunction with digital innovations like BIM & data sharing

Rail logistics

Europe's largest fleet of long rail transport units

User benefits

- Thanks to just-in-time logistics, rails of up to 180 m in length (also 240 up to 300 m) are transported reliably and quickly to the construction track

- Europe’s largest long rail transport fleet with state-of-the-art Robel & STS wagons including the necessary loading & unloading systems

- Precise localization via our own GPS positioning system & tracking in the web-based rail logistics portal

Focus on track availability

- Thanks to these capacities, we were able to win various major DB projects and complete them on schedule

- Smooth rail replacement for rapid resumption of operations

References

Numerous customers in Europe

Featured projects

- Riedbahn, Germany

- HSL KRM, Germany

- BaneDanmark, Denmark

Turnout logistics

Transport of complete turnout segments

User benefits

- Modern & environmentally friendly transport by rail (lower CO2 emissions) with special tilted wagons

- Digital turnout measurement with minimal impact on ongoing operations creates the conditions for smooth turnout conversion

- Production & delivery of complete turnouts for the fastest possible installation

- Construction sequence planning (logistics simulator) to plan the necessary track possessions even more efficiently & safely

- Generally, we also offer to take the old turnouts away for refurbishment or disposal.

Focus on track availability

- The use of pre-assembled turnout modules as a plug & play solution in combination with just-in-time delivery allow a 30 % reduction of the on-site installation time.

References

- Across Europe

- Example Sweden: Delivery, removal, installation & complete installation within 8 hours – then immediately ready for operation again

Turnout installation

Fastest & most safest way

User benefits

- Uniform high quality of the turnout construction thanks to the stationary production in the turnout plant installed using a crane in just a few hours.

- Economic benefits through significantly shortened track construction work & reduced manpower requirements at the site. Moreover, no staff with turnout experience are needed in the track – a crucial advantage in times of personnel shortage, which also results from the demographic change.

- High level of safety in the track

Focus on track availability

- Quick unloading & installation; five

times faster as a traditional approach - Short track possessions & less noise

- No on-site assembly area required

- BIM for more efficient projects

- Turnout monitoring optimize the maintenance management

References

- Sweden: ca. 250 turnouts p.a. since 1999

- Norway: ca. 100 turnouts p.a. since 2003

- Finland: ca. 80 turnouts p.a. since 1994

- Denmark: ca. 80 turnouts p.a. from 2024

Mobile flash-butt welding

Without the introduction of any foreign material

User benefits

- One of the most advanced technologies for producing a seamless track body

- Higher quality & strength

- Greater process stability & high reproducibility of the result in mass production due to processor control → No additional ultrasonic testing required

- High quantities in a short period (up to 8 welds per hour) for fast work progress

- No foreign materials are employed → much safer working conditions & more environmentally friendly

Focus on track availability

As a result of our processor controlled, fully automatic flash-butt welding process, these welded joints are less prone to failure and ensure a significantly higher strength & durability.

References

- On the process & machine side, we have numerous country approvals as well as sufficient capacity to successfully complete major construction sites

- References on four continents

smart HSG

Smart maintenance on the fly

User benefits

- The innovative High Speed Grinding (HSG) process is the only technology in the world that enables rail maintenance at working speeds of up to 80 km/h in regular train traffic without line closures.

- Due to the elongated area of contact, the grinding wheels remove brittle surfaces (hardened surface layer) and the beginnings of corrugations and slip waves

- Reliable prevention & limitation of fault proliferation

- Efficient noise reduction thanks to a transverse groove-free process

Focus on track availability

- The innovative High Speed Grinding (HSG) process is the only technology in the world that enables rail maintenance at working speeds of up to 80 km/h in regular train traffic without line closures.

- Rail service life extended by up to 100 % → Rail replacement moved significantly into the future

References

- In China, the HSG-2 has been officially recommended by the Chinese Ministry for the maintenance of PDLs since 2019.

- The HSG-2 grinds approx. 13,000 km per year in the German high-performance network

smart HSG

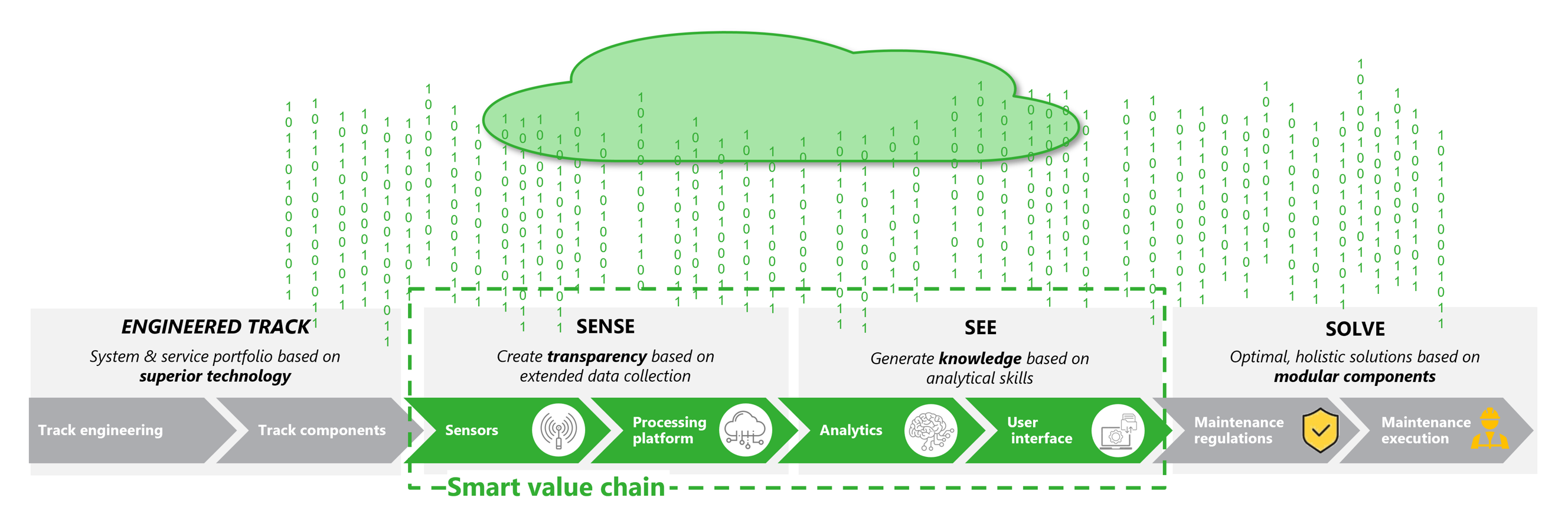

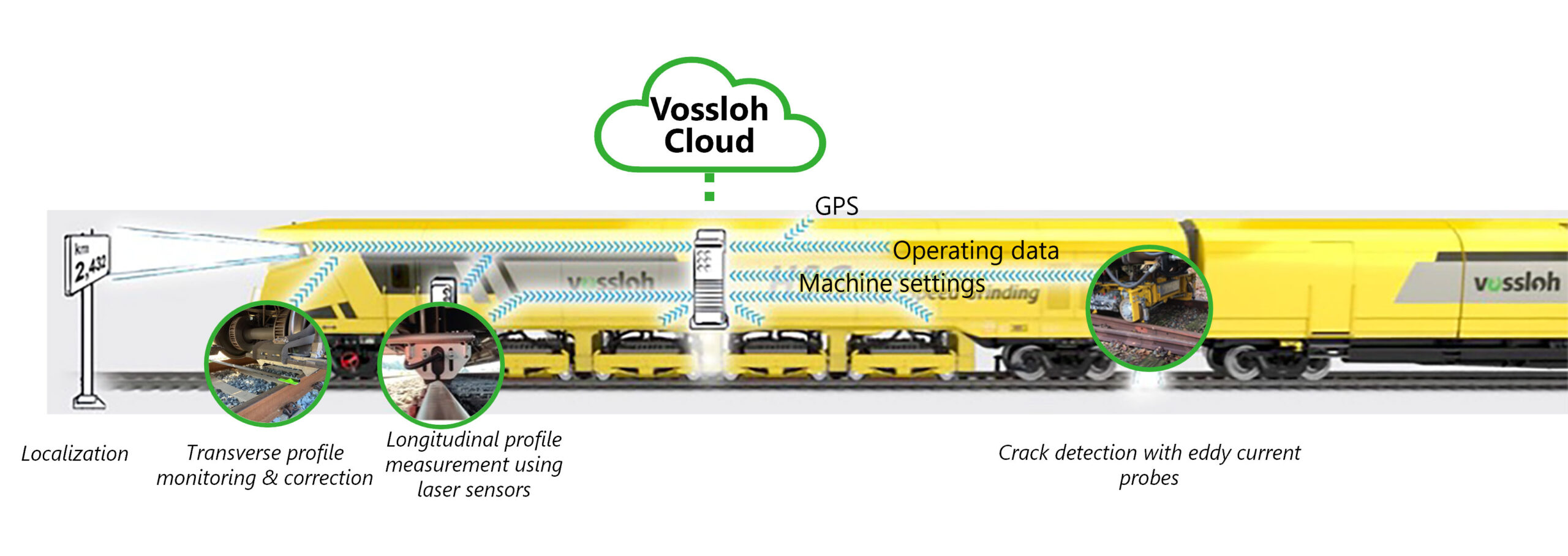

The future belongs to digital-based rail processing

User benefits

- Measurement data enables optimal planning of our rail processing

- Knowing the condition of the rail network is the essential lever to intelligent and efficient rail maintenance.

- Integrated measurement technology for performing transverse & longitudinal profile measurements and eddy current testing

- Sensor technology works relatively autonomously and measures both rails simultaneously, which also makes it possible to determine the track gauge. The wear reserve in the rail head can also be measured using transverse profile measurement.

- Intelligent evaluation of measurement data

- Processing is condition-oriented with the grinding track generator

Focus on track availability

- Measurements taken while the train is in motion enable daily reports on the track condition

- Maintenance measures tailored precisely to the needs of the track

- Disruption reduction

- Extended intervals for material-intensive processing → equates to fewer track closures

References

- New standard for HSG grinding machines

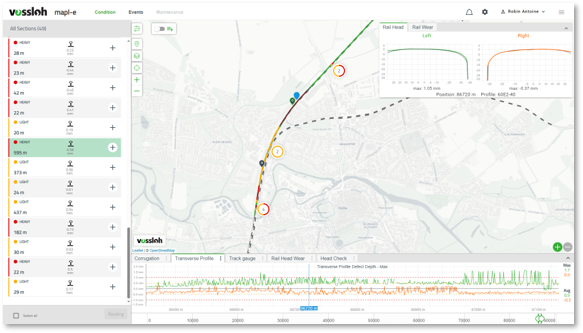

mapl-e enables condition-based rail processing

Smart maintenance as an evolutionary stage of HSG technology

User benefits

- mapl-e divides the measured track into different processing sections – depending on the type and depth of the fault – and visualizes the track condition intuitively with traffic light colors.

- Simplified evaluation of good, bad and critical can be adjusted quickly and easily at any time via tolerance bands by changing the threshold values and their effects on shift performance and costs.

- The forecasting capability increases with each cycle

- Rail condition can be simulated & corresponding rail processing procedures can be scheduled

Focus on track availability

- The complete overview makes it possible to prioritize the route sections which are to be worked on and to plan appropriate measures in a targeted manner

- Simplifies the entire planning & control process for rail maintenance

Alternatively, the compact smart HSG-city is available

Over 40 compact machines are in use worldwide with great success

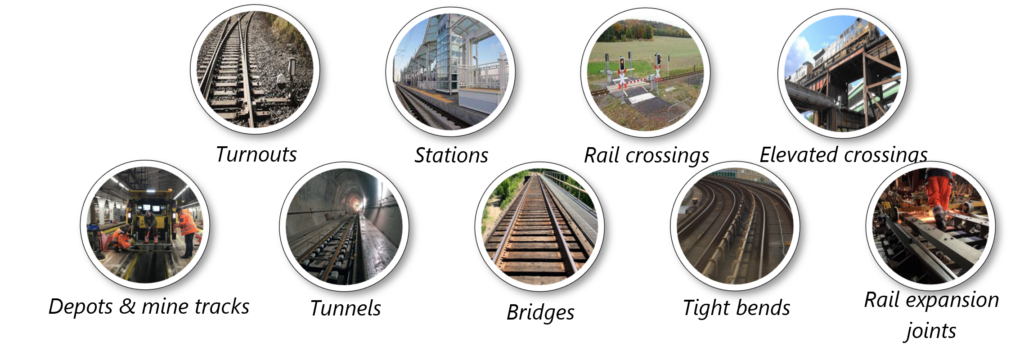

Preventive turnout rail maintenance

The most flexible solution: System Flexis

User benefits

- Vossloh’s all-round system for the rail maintenance of complete turnouts and common crossing assemblies. The system also machines the frog & point blades, which cannot be accessed by larger equipment.

- Combines highly accurate measuring techniques with technically versatile machines for effective, cost-efficient machining and care that accommodate the unique features of every turnout.

Focus on track availability

- Ideal solution in all weather conditions – quick & easy – when the entire rail head area of turnouts and shorter track sections need a reprofiling & reconditioning with a material removal from preventive to corrective (up to 1.5 mm and for individual defects up to 3 mm).

- For an exhaust & noise reduction: electric Flexis machines

References

Across Europe & in North America

Application Areas & Specialities

The most flexible solution: System Flexis

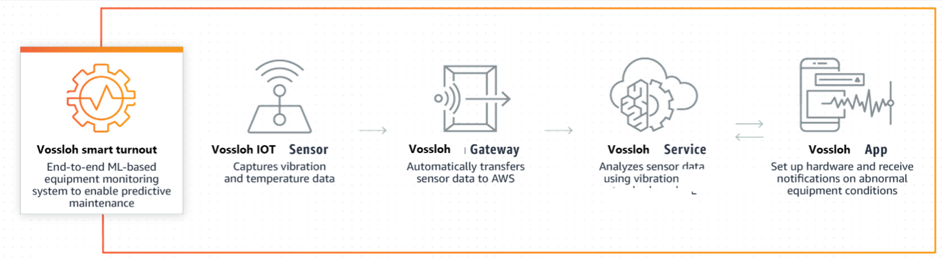

Smart Turnout

Continuous monitoring of turnouts

Solution

User benefits

- Optimized maintenance cycles:

- Asset Insight from automatic data-driven analytics (based on infrastructure expert knowledge)

- Proactive maintenance management

- 24/7 online monitoring of turnout asset:

- Data available with time stamp: vertical displacement, turnout vibration, train type & speed, total number of trains

- Asset status indicator & automatic alarms

- Asset monitoring device fleet management

- Ease of implementation of the sensor & gateway (quick installation)

- Wireless connectivity & cloud based data management and visualization

Smart Turnout Acquisition Device

Continuous monitoring of turnouts

Focus on track availability

- Optimized maintenance cycles:

- Detect turnout asymmetry before maintenance limits

- Anticipate evolution of degradation & give a support to prioritize maintenance

- Revise the maintenance specifications in the medium term

- Increase asset lifespan by ensuring on time intervention

- Confirm & check the quality of maintenance works (e.g. tamping works) by checking the return to nominal condition

SoniQ Rail Explorer incl. ultrasonic manganese inspection

Continuous monitoring of turnouts

User benefits

- Detects irregularities in the rail interior, volume defects in the rail head, web & base as well as corrosion at the rail base incl.

a classification & determination of the size of the defect - Multiple viewing modes to inspect the rail, incl. A-scan with multi-view, B-scan & synchronized camera image

- Enables condition monitoring of crossings made of cast manganese steel. The manual probes developed in partnership with UltraRS detect discontinuities in the cast manganese crossing interior to a depth of at least 60 mm below the running surface.

Focus on track availability

- Hand-held testing device for pinpointing & regular inspections on short track sections, switches, crossings, level crossings and stations

- No interference with trackside switching equipment or track circuits

- Manual probes can be used directly on the SRE or on a separate electronics box (PCUS pro® Single)

Potential

- In Europe & Asia

Corrective Rail maintenance

User benefits

- Corrective rail milling gives the rail a new lease of life.

- Even deep rail defects can be completely eliminated.

- The advantages of the milling process comprise the

- continuous transverse profile,

- high material removal in a single pass and

- uniform quality of the rail surface.

Focus on track availability

- As the European market leader, Vossloh has the largest fleet of milling machines

- The line will be closed for a comparatively short time in order to prevent a lengthy closure during the alternative, more costly rail replacement.

MillingXpress

HotSpot milling with VTM-compact

User benefits

- For the selective, fast & efficient removal of deep rail defects

- Reduces high number of fitting pieces/replacement rail exchanges

- Maximized rail service life

Focus on track availability

- Thanks to a logistical solution (“rolling highway”), transportation directly to the construction track is possible

- Lower personnel & planning costs

- No material procurement & logistics necessary

- Reducing the limited capacity of large mobile milling machines

Corrective turnout maintenance

The most flexible form of rail maintenance for turnouts

User benefits

- Perfect milling solution when maximum mobility, easy on-&-off railing – right at the work site where possible – as well as short tooling times are the order of the day.

- Transport truck & machine in one

- Simple logistics & ideal for small-scale works & tram networks

- Transfer via road or rail

- Maximum mobility & flexibility

- Very environmentally friendly: minimal production of dust & sparks

Focus on track availability

- Machining of the entire profile in just a single pass

- Achieving a low-noise rail surface quality what extends the rail‘s service life

- No dismantling of trackside switching & signaling equipment required

References

- Europe-wide

Corrective turnout maintenance

The perfect combination

User benefits

- Depending on the number of turnouts to be machined in a shift, a combined deployment with our milling truck & Flexis is recommended. Turnout processing time can be reduced considerably with the milling truck especially when material removal exceeds 0.5 mm. This method allows several turnouts per shift and various connecting lengths of track to be processed.

- Thanks to a specially constructed tool & an adjustment of the software for the machining process, it is possible to mill more than 95 % of a turnout.

- Complete reprofiling of the straight & diverging sections of the turnout incl. crossing (frog), wing rail and switch rail zone down to a width of 20 mm.

- Grinding with the Flexis System, specifically designed for the maintenance of

turnouts, is then only required for the alignment work in the transition zones. - The corrective repair measures of Flexis includes deposition welding where required.

- All turnouts with cast crossings (frogs) and swing nose crossings can be machined.

- Not recommended for economic reasons: single-slip turnouts, double-slip turnouts and line intersections.

Focus on track availability

- Simple on-railing & off-railing – right at the work site where possible

- Machining of the entire profile in just a single pass

- No dismantling of trackside switching and signalling equipment required

- Minimal time required for machining

- Reprofiling returns the turnout to near-new condition

References

All over Europe

Rail replacement

Vossloh‘s assembly line rail replacement system

Focus on track availability

- Shorter track possessions & construction periods thanks to the module‘s non-stop operation

- Integrated production of continuously welded track using mobile flash butt welding

- Cost-effective deployment thanks to the combination of unloading & replacement procedures

- Long-rail transport unit used for delivery & removal

- Uninterrupted process monitoring

- Full compliance with the rail’s prescribed bending line

References

- Europe-wide

Adopting the GS1 standard

For an optimized rail infrastructure management

A unique identifier to follow our product all along its lifecycle from production to asset management and end of life.

Focus on track availability

- Unique IDs: Each product is given a unique number, similar to an ID card number, guaranteeing precise, unambiguous identification that remains unchanged over time.

- Global interoperability: GS1’s global standards facilitate communication between partners (suppliers, customers, maintainers), ensuring that everyone speaks the same language and uses the same unique identifier for each asset.

- Improved safety & reliability: Standardized component identification & tracking ensures easy access to essential information, improving the safety and reliability of rail operations.

- Regulatory compliance: Helps companies in the rail sector to comply with regulatory requirements in terms of safety & quality management, thereby reinforcing compliance with national & international standards including the future European Digital Product Passport (DPP) regulation.

- Enhanced traceability: Ensures detailed tracking of components & rolling stock through-out their lifecycle, guaranteeing complete traceability & increased accountability.

- Efficient data exchange: Enables data sharing seamlessly between all the partners involved, whether internal to the company or multilateral.

Reference

- In Australia since 2018: Today, more than 600 Vossloh Cogifer turnouts are identified with this type of tag containing the unique identifier & various other elements legibly inscribed and partially encoded in data matrix.

GS1 is a neutral, not-for-profit international organization, created by companies and dedicated to the development of global standards for the identification, communication & sharing of information between companies.

Founded in 1973, GS1 enables companies to uniquely identify their products, logistics units, locations, entities & equipment throughout their lifecycle.

Manganese recycled crossing

In the environmentally friendly circular economy

User benefits

- Recycled manganese crossings create a sustainable product by transforming the metallurgic process, logistics, and procurement agreements into a circular economy model. This approach ensures price and volume stability, reduces CO2 footprints, and enhances customer relationships by making them suppliers of raw material.

- Challenges like controlling alloy composition and optimizing energy losses are addressed through testing, specialized machinery, and logistics adjustments. Stakeholder involvement and tools like CO2 impact calculators and life cycle analyses support the project’s sustainability goals.

Focus on track availability

- Manganese crossings have the greatest lifespan

- Great improvement in terms of environmental footprint

- The circular economy approach ensures price and volume stability by recycling dismantled crossings

- Recycling manganese not only reduces CO2 emissions but also mitigates the environmental, health, and social impacts associated with manganese extraction, aligning with the company’s sustainability goals.